Website:

motrona

Website:

motrona

Catalog excerpts

Industrial automation safety - control - motion - interface

Open the catalog to page 1

Contents SAFETY RELAYS Safety Speed Monitors with SIL certification Device Types Technical Data Our Classics Applications DIGITAL INDICATORS Digital- and touchMATRIX® Indicators Types Device Technical Data Our Classics Applications MOTION CONTROLLER Universal Motion Controller Device Types Technical Data Our Classics Applications SIGNAL CONVERTERS Signal Converters - Signal Distributors - Gateway Device Types Technical Data Our Classics Applications

Open the catalog to page 2

Device Types SAFETY RELAYS Safety Speed Monitors with and The safety of man and machine in production processes is the top priority, we guarantee for that with our speed monitors! Fulfilling the highest security standards, our devices offer maximum protection. These safety standards are verified by a double certificate EN 61508 and ISO 13849 by TÜV Nord. The focus of our safety relays is on monitoring movement sequences such as speed, standstill, direction of rotation and position. In order to implement further control and regulation purposes, our safety devices offer signal feedback via...

Open the catalog to page 3

Safety speed monitor 2-channel for sine/cosine encoders or 2-channel for sine/cosine and incremental encoders Safety speed monitor 1-channel for sine/cosine encoders Forced-guided redundant relay contacts (NO) Control outputs short-circuit-proof, [HTL / push-pull] Analog output 4 ... 20 mA (safety related), 14 Bit Safety monitors for incremental encoders / sensors Security level • Signal distributor Encoder interface Safety speed monitor 2-channel for sine/cosine encoders or 2-channel for sine/cosine and incremental encoders Encoder systems Article number Technical Data Monitor for speed,...

Open the catalog to page 4

Applications Load monitoring In the operation of cable cars, the safety of passengers is of pramount importance. In order to guaran- and unwinding speed and the safe standstill monitoring of the hoist rope. Especially when it comes to tee safe transport, unintentional opening of the doors must be ruled out. So the door locking is monitored great heights, e.g. with tower cranes, it is also possible to monitor the wind speed. Thereby a uncontrolled movement of the cable, an emergency stop of the cabine is triggered. In turbines, kinetic energy is generated by gas or fuel. To ensure that the...

Open the catalog to page 5

DIGITAL INDICATORS Device Types • Process indicator with analog input Sensors: analog sensors ± 10 V or 0/4 ... 20 mA Digital- and touchMATRIX® Indicators Measured variables: inclination (inclinometer), length, acceleration, pressure, flow rate • Incremental indicator for frequencies up to 1 MHz Sensors: incremental encoders, light barriers, proximity switches, linear scale Measured variables: speed, frequency, length, quantity, time Our unique touchMATRIX® indicators are widely used in industry as Smart HMI. Due to the different versions for analog, pulse, absolute value and strain gauge...

Open the catalog to page 6

• Bright and high-contrast display with event-dependent color variations • 4 preset / limit values • Panel housing (w x h x d) 96 x 48 x 116 mm / 3.78 x 1.89 x 4.56 inch • Protection class IP65 Electronic counters / tachometers (input frequency up to 1 MHz) Combi counter / tachometers (input frequency up to 1 MHz) • Power supply 24 VDC SSI (DATA, CLOCK) 6 decades or 8 decades with Process indicator with analog input • Freely editable symbols and units • Numerous functions: scaling, filter, start-up suppression • Linearization with 24 control points Optional interface • Intuitive and easy...

Open the catalog to page 7

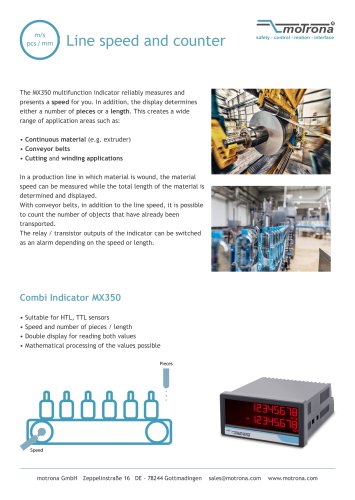

Applications Speed Flow Circumference Diameter In production lines with endless material, depending the adjustable material thickness the roll grinding machines. Another application is monitoring the speed of axes, shafts and rollers.In addition circumference and diameter can be calculated automatically with each full rotation. A precise to the rotary movements, the devices are also used for the line speed used on conveyor belts, extrusion visualization of the cutting length is also possible in following cutting processes. There is no difference lines and printing machines. This makes it...

Open the catalog to page 8

MOTION CONTROLLER Universal Motion Controller Device Types Motion controller for up to 4 axes Number of following axes cascadable Interface for CANopen, Modbus RTU Firmware options for various applications: Synchronization, flying operation, rotary material processing, Our motion controllers are implemented in numerous applications in the field of modern drive technology. The existing firmware library includes optimized routines for typical applications such as • • • • • • • • Electronic drive synchronization Index and print mark control Rotating cross cutters Flying saws Eccentric shears...

Open the catalog to page 9

Signal formats Control inputs Our Classics Article number Technical Data RS232 with Printer CR/LF Drivecom DIN ISO 1745 Analog output Analog (V, mA), 4 Transistors, 4 Relays RS232 with Printer CR/LF Drivecom DIN ISO 1745 PROFIBUS-DP connection possible RS232 with Printer CR/LF Drivecom DIN ISO 1745 Synchronization, flying operation, rotary material processing, position control Control for one following axis with 4 relays Thumbwheel switches Flying operation Flying operation Analog (V, mA) 4 Transistors, 4 Relays Modbus RTU, Printer CR/LF Drivecom DIN ISO 1745 Rotary cross cutter RS232 with...

Open the catalog to page 10

Applications Rotary material processing Motion controllers allow rotary cross cutters to be precisely synchronized with the material speed. A In tubular bag machines drives are placed at various points, e.g. at the conveyor belt of the products, rotary encoder transmits the frequency to the controller, which regulates the drive of the cross cutter. By at the feed of the foil and at the cutting tool. The motrona motion controllers synchronize the cutting sensors at the cutting tool, the process is constantly monitored and controlled. Accurate cuts can thus tool and the conveying speed of the...

Open the catalog to page 11All Motrona catalogs and technical brochures

-

Product portfolio

1 Pages

-

Profinet Indicator

1 Pages

-

Force Measurement

1 Pages

-

Wind warning devices

2 Pages

-

Load monitoring

2 Pages