Catalog excerpts

XP Parallel Index Drives Rotary Indexer

Open the catalog to page 1

Application examples Direct driven belt/chain M = Mb + Mb Calculations J = moment of inertia *with one-sided lifting of loads Man = drive torque [Nm] j = friction coefficient g = acceleration of gravity = 9,81m/s2 R = radius m = mass [kg] a = switching angle [°] ts = index time [s] n = number of stops i = ratio P = drive power [kW] n = efficiency worm gear fa = drive speed [1/min] Indirect driven belt/chain M Transducer of rotations in horizontal movement M = M + M a becomes a’ b will be removed

Open the catalog to page 2

XP030 Dimensions The measurements shown here illustrate the standard unit. We will gladly customize the housing and or shaft(s) to suit your needs. The drive shaft as well as the output shaft are available as double sided shafts with and without a keyway. If you would like to add additional holes into the housing yourself, please contact us for possible drilling depths. A =Drive shaft Configuration of all parallel drives The dimensions for the gearmotor may change based on the gearmotor size and options required for the application.

Open the catalog to page 3

1) Parallel drives with stop numbers 6, 8 and 10 are designed as a double index, i.e. with each full rotation of the drive shaft, two indexes occur in the output. 2) Parallel drives with 12 stops are designed as a four step index, i.e. with each full rotation of the drive shaft, four indexes occur in the output. 3) The additional load occurring with chains and belts due to friction is not taken into consideration here and must be calculated separately. Main Dimensions Capacities Shaft distance [mm] 30 Weight without drive [kg] 0.7 Index angle [°] see Load Table (other index angles upon...

Open the catalog to page 4

XP040 Dimensions The measurements shown here illustrate the standard unit. We will gladly customize the housing and or shaft(s) to suit your needs. The drive shaft as well as the output shaft are available as double sided shafts with and without keyways. If you would like to add additional holes into the housing yourself, please contact us for possible drilling depths. A = Drive Shaft The dimensions for the gearmotor may change based on the gearmotor size and options required for the application.

Open the catalog to page 5

1) Parallel drives with stop numbers 6, 8 and 10 are designed as a double index, i.e. with each full rotation of the drive shaft, two indexes occur in the output. 2) Parallel drives with 12 stops are designed as a four step index, i.e. with each full rotation of the drive shaft, four indexes occur in the output. 3) The additional load occurring with chains and belts due to friction is not taken into consideration here and must be calculated separately. Max. Output torque Input Shaft Load rating dynamic [kN] Load rating static [kN] Output Shaft Load rating dynamic [kN] Load rating static...

Open the catalog to page 6

XP050 Dimensions The measurements shown here illustrate the standard unit. We will gladly customize the housing and or shaft(s) to suit your needs. The drive shaft as well as the output shaft are available as double sided shafts with and without keyways. If you would like to add additional holes into the housing yourself, please contact us for possible drilling depths. A = Drive Shaft The dimensions for the gearmotor may change based on the gearmotor size and options required for the application.

Open the catalog to page 7

1) Parallel drives with stop numbers 6, 8 and 10 are designed as a double index, i.e. with each full rotation of the drive shaft, two indexes occur in the output. 2) Parallel drives with 12 stops are designed as a four step index, i.e. with each full rotation of the drive shaft, four indexes occur in the output. 3) The additional load occurring with chains and belts due to friction is not taken into consideration here and must be calculated separately. Max. Output torque Input Shaft Load rating dynamic [kN] Load rating static [kN] Output Shaft Load rating dynamic [kN] Load rating static...

Open the catalog to page 8

XP065 Dimensions The measurements shown here illustrate the standard unit. We will gladly customize the housing and or shaft(s) to suit your needs. The drive shaft as well as the output shaft are available as double sided shafts with and without keyways. If you would like to add additional holes into the housing yourself, please contact us for possible drilling depths. A = Drive Shaft The dimensions for the gearmotor may change based on the gearmotor size and options required for the application.

Open the catalog to page 9

Load Table 1) Parallel drives with stop numbers 6, 8 and 10 are designed as a double index, i.e. with each full rotation of the drive shaft, two indexes occur in the output. 2) Parallel drives with 12 stops are designed as a four step index, i.e. with each full rotation of the drive shaft, four indexes occur in the output. 3) The additional load occurring with chains and belts due to friction is not taken into consideration here and must be calculated separately. Main Dimensions Capacities Shaft distance [mm] 63 Weight without drive [kg] 8 Index angle [°] see Load Table (other index angles...

Open the catalog to page 10

XP080 Dimensions The measurements shown here illustrate the standard unit. We will gladly customize the housing and or shaft(s) to suit your needs. The drive shaft as well as the output shaft are available as double sided shafts with and without keyways. If you would like to add additional holes into the housing yourself, please contact us for possible drilling depths. A = Drive Shaft The dimensions for the gearmotor may change based on the gearmotor size and options required for the application.

Open the catalog to page 11

1) Parallel drives with stop numbers 6, 8 and 10 are designed as a double index, i.e. with each full rotation of the drive shaft, two indexes occur in the output. 2) Parallel drives with 12 stops are designed as a four step index, i.e. with each full rotation of the drive shaft, four indexes occur in the output. 3) The additional load occurring with chains and belts due to friction is not taken into consideration here and must be calculated separately. Max. Output torque Input Shaft Load rating dynamic [kN] Load rating static [kN] Output Shaft Load rating dynamic [kN] Load rating static...

Open the catalog to page 12All Motion Index Drives catalogs and technical brochures

-

RTF Rotary Index Tables

13 Pages

-

RTX Rotary Index Tables

20 Pages

-

TSR Series

13 Pages

-

TT315 Series

7 Pages

-

RT Series Rotary Index Table

14 Pages

-

Precision Link Conveyor

12 Pages

-

Weld Positioner

5 Pages

-

TMF Series Rotary Index Table

15 Pages

-

Pick and Place

5 Pages

-

Product Catalog

152 Pages

-

MX150 Slip Ring Brochure

2 Pages

-

MX470 Slip Ring Brochure

3 Pages

-

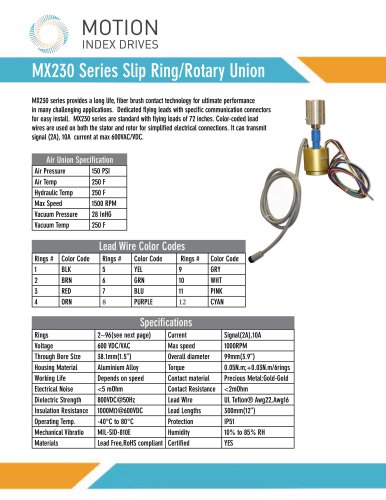

MX230 Slip Ring Brochure

2 Pages