Catalog excerpts

* Dimensions depend on the used drive

Open the catalog to page 2

Fitting position Load on output flange Load on central column Torque on output flange [Nm] 10 Axial runout on the output flange 0 [mm] * Increased indexing accuracy accessible through selected components From division 16, the division error due to multi-point locks on the drive cam is larger by a factor of 1.5“ Combined loads and possible process forces must be confirmed by Motion Index Drives. Standard drive Motor size

Open the catalog to page 3

Load table RTX350 n = Number of stops / 360° revolution of output flange t = Step time in [s] JMax = Mass moment of inertia (base plate + fixtures and parts) in [Kgm2] Without motor and lifetime JL = Mass moment of inertia by life time (base plate + fixtures and parts) in [Kgm2] J = Mass moment of inertia with motor (base plate + fixtures and parts) in [Kgm2] From n=16 The output flange steps 2 times per cam revolution From n=36 The output flange steps 3 times per cam revolution

Open the catalog to page 4

* Dimensions depend on the used drive

Open the catalog to page 5

Fitting position Load on output flange Radial force F,a [N] 17.5 Axial force F3a [kN] 20 Torque on output flange [Nm] 322 Load on central column Precision Axial runout on the output flange 0 [mm] * Increased indexing accuracy accessible through selected components From division 16, the division error due to multi-point locks on the drive cam is larger by a factor of 1.5“ Axial force FaM [kN] 18 Torque on output flange [Nm] 77 Combined loads and possible process forces must be confirmed by Motion Index Drives. Standard drive Output flange 0 Motor size

Open the catalog to page 6

Load table RTX450 n = Number of stops / 360° revolution of output flange t = Step time in [s] JMax = Mass moment of inertia (base plate + fixtures and parts) in [Kgm2] Without motor and lifetime JL = Mass moment of inertia by life time (base plate + fixtures and parts) in [Kgm2] J = Mass moment of inertia with motor (base plate + fixtures and parts) in [Kgm2] From n=16 The output flange steps 2 times per cam revolution From n=36 The output flange steps 3 times per cam revolution

Open the catalog to page 7

Position of the hole pattern in the output flange Stop number Further stop numbers you can find in the RTF/RTX550 dimension sheet at our website. * Dimensions depend on the used drive

Open the catalog to page 8

Fitting position Load on output flange Radial force FrA [kN] 23 Axial force FaA [N] 18.4 Torque on output Precision Axial runout on the output flange 0 [mm] * Increased indexing accuracy accessible through selected components From division 16, the division error due to multi-point locks on the drive cam is larger by a factor of 1.5“ Axial force FaM [kN] 18 Torque on output flange [Nm] 77 Combined loads and possible process forces must be confirmed by Motion Index Drives. Standard drive Output flange 0 Motor size

Open the catalog to page 9

Load table RTX550 n = Number of stops / 360° revolution of output flange t = Step time in [s] JMax = Mass moment of inertia (base plate + fixtures and parts) in [Kgm2] Without motor and lifetime JL = Mass moment of inertia by life time (base plate + fixtures and parts) in [Kgm2] J = Mass moment of inertia with motor (base plate + fixtures and parts) in [Kgm2] From n=16 The output flange steps 2 times per cam revolution From n=36 The output flange steps 3 times per cam revolution

Open the catalog to page 10

Fitting position Load on output flange Radial force FrA [kN] 20 Axial force FaA [kN] 22.5 Torque on Precision Axial runout on the output flange 0 [mm] * Increased indexing accuracy accessible through selected components From division 16, the division error due to multi-point locks on the drive cam is larger by a factor of 1.5“ Axial force FaM [kN] 14 Torque on output flange [Nm] 170 Combined loads and possible process forces must be confirmed by Motion Index Drives. Standard drive Output flange 0 Motor size

Open the catalog to page 12

Load table n = Number of stops / 360° revolution of output flange t = Step time in [s] JMax = Mass moment of inertia (base plate + fixtures and parts) in [Kgm2] Without motor and lifetime JL = Mass moment of inertia by life time (base plate + fixtures and parts) in [Kgm2] J = Mass moment of inertia with motor (base plate + fixtures and parts) in [Kgm2] From n=16 The output flange steps 2 times per cam revolution From n=36 The output flange steps 3 times per cam revolution

Open the catalog to page 13

* Dimensions depend on the used drive

Open the catalog to page 14

Fitting position Load on output flange Load on central column Axial runout on the output flange 0 [mm] Radial force FrM [kN] 3.8 Axial force FaM [kN] 15 Torque on output * Increased indexing accuracy accessible through selected components From division 16, the division error due to multi-point locks on the drive cam is larger by a factor of 1.5" Standard drive Motor size

Open the catalog to page 15

Load table RTX750 n = Number of stops / 360° revolution of output flange t = Step time in [s] JMax = Mass moment of inertia (base plate + fixtures and parts) in [Kgm2] Without motor and lifetime JL = Mass moment of inertia by life time (base plate + fixtures and parts) in [Kgm2] J = Mass moment of inertia with motor (base plate + fixtures and parts) in [Kgm2] From n=16 The output flange steps 2 times per cam revolution From n=36 The output flange steps 3 times per cam revolution

Open the catalog to page 16

* Dimensions depend on the used drive

Open the catalog to page 17

Fitting position Load on output flange Load on central column Axial runout on the output flange 0 [mm] * Increased indexing accuracy accessible through selected components From division 16, the division error due to multi-point locks on the drive cam is larger by a factor of 1.5“ Axial force FaM [kN] 25 Torque on output flange [Nm] 450 Combined loads and possible process forces must be confirmed by Motion Index Drives. Standard drive Output flange 0 Motor size

Open the catalog to page 18

Load table RTX900 n = Number of stops / 360° revolution of output flange t = Step time in [s] JMax = Mass moment of inertia (base plate + fixtures and parts) in [Kgm2] Without motor and lifetime JL = Mass moment of inertia by life time (base plate + fixtures and parts) in [Kgm2] J = Mass moment of inertia with motor (base plate + fixtures and parts) in [Kgm2] From n=16 The output flange steps 2 times per cam revolution From n=36 The output flange steps 3 times per cam revolution

Open the catalog to page 19All Motion Index Drives catalogs and technical brochures

-

RTF Rotary Index Tables

13 Pages

-

TSR Series

13 Pages

-

TT315 Series

7 Pages

-

RT Series Rotary Index Table

14 Pages

-

Precision Link Conveyor

12 Pages

-

Weld Positioner

5 Pages

-

TMF Series Rotary Index Table

15 Pages

-

XP Series

23 Pages

-

Pick and Place

5 Pages

-

Product Catalog

152 Pages

-

MX150 Slip Ring Brochure

2 Pages

-

MX470 Slip Ring Brochure

3 Pages

-

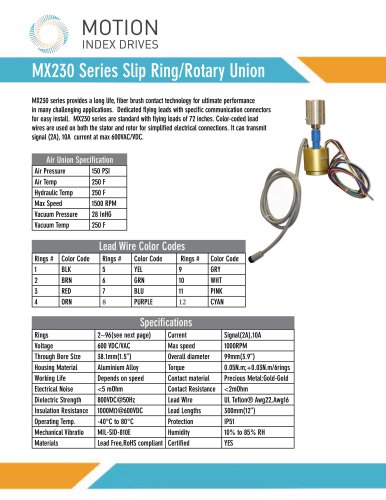

MX230 Slip Ring Brochure

2 Pages