Catalog excerpts

Omni-Lift Drum Rackers The Specialist In Drum Handling Equipment Lift, Rotate and Rack a Drum • Rack your drum up to 6’ (1.83 m) high Lift an upright or horizontal drum Control the lift height and tilt angle Easily handled by one person Heavy-duty hydraulics Capacity: 800 Lb (363 kg) full drum 500 Lb. (227 kg) half-full drum * Model 405 has hand pump drum lift and hand crank drum tilt control Use the Omni-Lift Drum Racker to pick up or place an upright or horizontal drum on the floor. Secure your drum in the holder with the web strap and ratchet. The drum holder is designed with strong teeth and redundant safety features for reliability and ease of use. Heavy duty hydraulic lift cylinders include a velocity fuse to provide a full line shut-off in the event of a line failure. Manual tilt models have hand crank tilt control with safety gear covers. We recommend the MORStop Tilt-Brake option (shown below) on all manual tilt models. Models with power lift and tilt provide a more ergonomic solution to drum handling (see side 2). Load a Morse drum roller Quickly and efficiently lift and rack your drum up to six feet (1.83 m) high. The Omni-Lift moves easily on its two 8” (20.3 cm) wheels and two 4” (10.2 cm) casters. Clearance for 8” wheels is required under the lowest shelf. Drum cradles on rack must be no wider than 16” (40.6 cm) for steel drum, or no wider than 11” (28 cm) for plastic drum. IMPORTANT: Add Kit # 3313 Plastic Drum Pad Kit for handling a rimmed 55-gallon plastic drum. You can place a 55-gallon (210 liter) steel drum onto the wheels of the open end of a Morse Stationary Drum Roller or onto a Portable Drum Roller (Not when equipped with accessory 3313-P). You may also use Omni-Lift Drum Rackers for controlled drum dispensing. Options and Accessories MORStop TM Tilt-Brake Handle a Rimmed 55-Gallon Plastic Drum Lift an upright plastic drum Turn drum to horizontal We recommend the MORStop Tilt-Brake to automatically stop and hold the drum tilt angle on models with manual tilt control! It functions smoothly and quietly in both directions. Without the MORStop TiltBrake, a heavy unbalanced drum may tilt out of control. Rack plastic drum in horizontal position Option # 3900i-P Factory installed on new unit with manual tilt. Plastic Drum Adaptor Kit # 3313-P provides pads to support the flexible sidewalls of a 55-gallon RIMMED plastic drum. The drum must have suitable top rim for chine catches to engage. Kit # 3900-P for customer to install on manual tilt model. Not for placing plastic drum onto rotator. NOTE: Drum cradle on rack must be no wider than 11” (28 cm) for plastic drum. * Half-full rating is an indication of capacity for tilting an unbalanced, bottom-heavy drum. A partially full drum with a shifting load is harder to tilt than a full drum. NOTE: Models with spark resistant parts already include spark resistant Poly Drum Pad Kit.

Open the catalog to page 1

The Specialist In Drum Handling Equipment Omni-Lift Drum Rackers Secure drum into holder by tightening the web strap and ratchet between the drum ribs. Approach upright drum with drum racker with two chine catches below the drum rim. Raise drum and rotate to horizontal drum racking position. Once drum is horizontal, release the web strap and ratchet. Drum then rests in cradle to enable placing it into a rack. Rack a drum up to 72” (183 cm) high with a Morse Omni-Lift Drum Racker. Model 405 shown has hand pump drum lift and hand crank drum tilt control. Place drum onto drum rack. Then back...

Open the catalog to page 2

Omni-Lift Drum Rackers The Specialist In Drum Handling Equipment Models with Factory Installed Power Lift Models with Factory Installed Power Lift and Tilt Power-Lift Models ease drum lifting, but retain manual tilt control. Drum tilt control is by hand crank. Gear covers are included on all Omni-Lift Drum Rackers. Model # Motor Type Power Lift and Tilt Models make drum handling easier and faster. There are two hand valve controls: One for the power-lift function and a second for power-tilt. Motor Control Motor Type Motor Control Switch, cord & plug Switch, cord & plug On/Off valve * On/Off...

Open the catalog to page 3

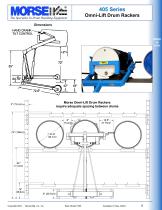

The Specialist In Drum Handling Equipment Omni-Lift Drum Rackers Morse Omni-Lift Drum Rackers require adequate spacing between drums

Open the catalog to page 4

The Specialist In Drum Handling Equipment Omni-Lift Drum Rackers Straddle Left Upright Inside Left Upright

Open the catalog to page 5

The Specialist In Drum Handling Equipment Omni-Lift Drum Rackers Inside Right Upright MADE IN USA

Open the catalog to page 6All Morse Mfg. Co. catalogs and technical brochures

-

Hydra-Lift Karriers

3 Pages

-

311 Series

2 Pages

-

310 Series

6 Pages

-

Tilt-To-Load Drum Tumblers

5 Pages

-

Hydra-Lift Drum Rollers

5 Pages

-

201 Series

6 Pages

-

1-5154 Series

5 Pages

-

611 and 620 Series

5 Pages

-

195 Series

3 Pages

-

Models 185XGR & 185XMGR

3 Pages

-

305 Series Can Tumblers

3 Pages

-

Model 14 Round Drum Dolly

2 Pages

-

160 4-Wheel Drum Trucks

2 Pages

-

Drum Lifters 90

3 Pages

-

309 series

4 Pages