Catalog excerpts

Molten Metal Systems Syncarb Z2 e2 Crucibles DESCRIPTION Syncarb Z2 e2 is a premium quality hybrid ceramic bonded clay graphite crucible with a high silicon carbide and graphite content that is manufactured through an advanced iso-static pressing process. Molten Metal Systems uses a proprietary processing technology that results in a product with a very homogenous and high density structure. This allows the crucible to obtain superior thermal conductivity over its entire operating temperature range, high mechanical strength and erosion resistance along with good shock resistance. These properties translate into a durable and robust crucible with excellent performance characteristics in lower temperature environments. In addition, Syncarb Z2 e2 also features proprietary internal and external glazes to prevent low temperature oxidation and degradation that occur in aluminum and other low temperature alloys over extended periods of time. APPLICATIONS Syncarb Z2 e2 is designed to perform exceptionally well to melt and hold aluminum and other low temperature alloys in gas and electric resistance furnaces TYPICAL METAL CASTING TEMPERATURE • Metal casting temperature between 400°C and 1000°C (752°F and 1832°F) PERFORMANCE CHARACTERISTICS • • • • • Extremely high oxidation resistance. Very good thermal conductivity. Very good resistance to chemical attack. High mechanical strength and good erosion resistance. Good thermal shock resistance. IDENTIFICATION Syncarb Z2 e2 crucibles are finished with a gray Low Temperature Protection (LTP) coating. PATTERN RANGE Syncarb Z2 e2 crucibles are available in a range of shapes and sizes to suit most end user requirements. Certain sizes can be made available with pyrometer pocket to facilitate measurement of metal temperature. A wide range of pouring lips are available. QUALITY Syncarb Z2 e2 crucibles are manufactured from premium grade raw materials under an ISO 9001:2008 quality management system. For additional information on MMS’ products & services or to find a location nearest to you, please visit: www.morganmms.com All dimensions are subject to normal manufacturing tolerances. Molten Metal Systems reserves the right to change specifications at any time. Not responsible for any typographic errors. www.morganmms.com © 2013 Molten Metal Systems, a business of Morgan Advanced Materials.

Open the catalog to page 1All Morgan Molten Metal Systems catalogs and technical brochures

-

Morganite® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

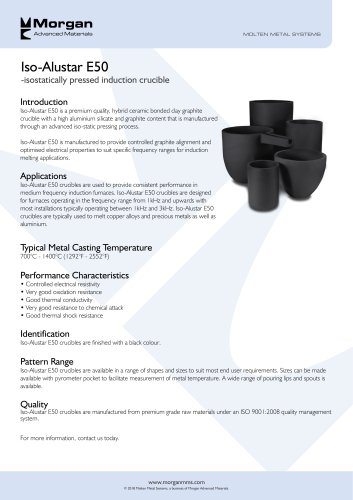

Alustar E50

2 Pages

-

ResCoat Coating

2 Pages

-

Z2e² PRO Coating

2 Pages

-

Degassing Rotors

2 Pages

-

Ladle Liners

2 Pages

-

Stabil

2 Pages

-

Grafit

2 Pages

-

Excel & Himelt

8 Pages

Archived catalogs

-

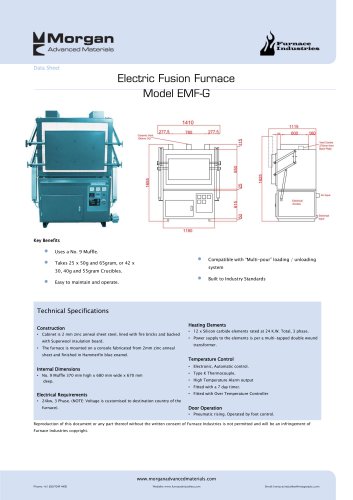

Morgan MMS Furnace Range

4 Pages

-

Crucible Lifter

2 Pages

-

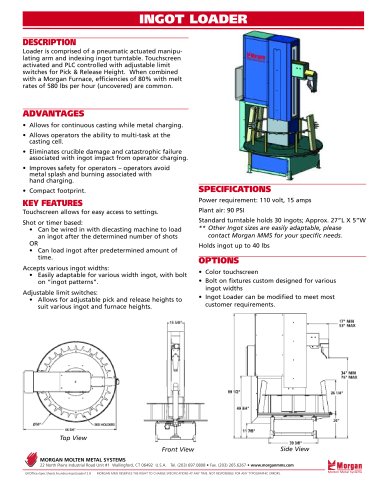

Ingot Loader

1 Pages

-

Foundry Products

2 Pages

-

Ultramelt Crucible Brochure

6 Pages

-

Crucible Accessories

4 Pages

-

Excel HiMelt Brochure

6 Pages

-

IsoAlustar Crucible Brochure

6 Pages

-

Salamander Crucible Brochure

4 Pages

-

Ultramelt Crucible Brochure

4 Pages

-

Indux Crucible Brochure

4 Pages

-

Starrbide Crucible Brochure

6 Pages

-

Excel E Crucible Brochure

4 Pages