Catalog excerpts

Innovating tomorrow’s solutions . . . today STABIL Crucibles DESCRIPTION Noltina‘s Stabil crucibles are carbon-bonded silicon carbide crucibles, which are characterised by very good thermal conductivity and high oxidation resistance. Due to their carbon content, these SiC crucibles have excellent stability at high temperatures and are therefore particularly suitable for processes where the temperature is changing frequently and where high heating rates are utilized. APPLICATIONS Noltina‘s Stabil crucibles are particularly suitable for processes with frequently changing temperatures and high heating rates. Stabil crucibles can be used for the holding of all non-ferrous alloys. They have a very high mechanical strength and a high refractoriness, making them especially suitable for melting heavy metal alloys. Additionally, they are resistant to chemical attack by fluxes. The standard Stabil crucibles are suitable for electric resistance heated and fuel fired furnaces for melting and holding with a melting temperature between 700°C and 1200°C. They perform well under difficult operating conditions. As a consequence of user-related innovative developments, optimised Stabil variants are available, especially for the higher temperature range up to 1400°C. They are particularly appropriate for melting copper and bronze alloys in furnaces with high power and high heating rates. TYPICAL METAL CASTING TEMPERATURE • 700 - 1200°C (1292 - 2192°F) PERFORMANCE CHARACTERISTICS • • • • • Outstanding thermal shock resistance. Very good thermal conductivity. High oxidation resistance. Very high mechanical strength. Good resistance to chemical attack. IDENTIFICATION Noltina‘s Stabil crucibles are coloured black and utilize the suffix C to denote the type. MorganMMS is a business within the MEM Division of The Morgan Crucible Company plc. PATTERN RANGE Noltina‘s Stabil crucibles are available in a wide range of sizes and shapes. QUALITY Noltina‘s Stabil crucibles are manufactured from premium grade raw materials under an ISO 9001:2008 quality management system. PREHEATING/FIRST USE Crucibles should be preheated empty until they reach a bright-red color. Heat to 200ºC (400ºF) over two hours. Heat at full power to 950ºC (1750ºF). Hold at this temperature for one hour. The cover should be in place throughout the process. This procedure drives off any moisture absorbed in shipping and sets the glaze to achieve maximum oxidation resistance CHARGING As soon as the crucible becomes hot all over, charge and melt immediately. Charge light returns first to form a cushion for heavier metal to follow. Use tongs to charge ingots. Place large pieces and ingots vertically.

Open the catalog to page 1

TILTING FURNACES The use of a base block made of the same material will ensure uniform heating of the crucible base and help reduce thermal strains. The base block should have the same or slightly larger diameter as the base of the crucible to provide ad- equate support For optimum heat transfer and melting efficiency, the height of the base block should be such that the base of the crucibles is level with the center line of the burner.The base blockand crucible should be installed The crucible should have a 3mm (1/8") gap between the top edge of the crucible and the cover, to allow for...

Open the catalog to page 2All Morgan Molten Metal Systems catalogs and technical brochures

-

Morganite® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Alustar E50

2 Pages

-

ResCoat Coating

2 Pages

-

Z2e² PRO Coating

2 Pages

-

Degassing Rotors

2 Pages

-

Syncarb Z2 e2

1 Pages

-

Ladle Liners

2 Pages

-

Grafit

2 Pages

-

Excel & Himelt

8 Pages

Archived catalogs

-

Morgan MMS Furnace Range

4 Pages

-

Crucible Lifter

2 Pages

-

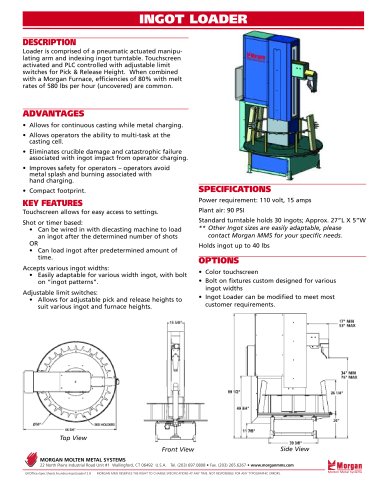

Ingot Loader

1 Pages

-

Foundry Products

2 Pages

-

Ultramelt Crucible Brochure

6 Pages

-

Crucible Accessories

4 Pages

-

Excel HiMelt Brochure

6 Pages

-

IsoAlustar Crucible Brochure

6 Pages

-

Salamander Crucible Brochure

4 Pages

-

Ultramelt Crucible Brochure

4 Pages

-

Indux Crucible Brochure

4 Pages

-

Starrbide Crucible Brochure

6 Pages

-

Excel E Crucible Brochure

4 Pages