Catalog excerpts

MOLTEN METAL SYSTEMS Case Study ResCoat Coating -better erosion resistance & increased production output Product name: ZYLS 815 x 610 with ResCoat Coating Copper alloy melting Parameters Furnace: Casting temperature: SnPbZn - Copper - Alloy Picture: BNS 600 PT with ResCoat Coating Benefits – Comparison of Syncarb with ResCoat Coating against existing crucible* better erosion resistance increased lifetime less crucible change overs higher metal output *For more details, please refer to page 2. www.morganmms.com © 2018 Molten Metal Systems, a business of Morgan Advanced Materials.

Open the catalog to page 1

MOLTEN METAL SYSTEMS M Morgan f Advanced Materials Existing Crucible The customer was using an ISO pressed, clay bonded, cylindrical crucible for melting a Copper alloy in an induction furnace at 1 80 Hz. The low frequency operation created significant metal movement during melting which was wearing off the crucible faster and led to failure of the crucible by erosion. Syncarb with ResCoat Coating With ResCoat, the customer achieved 20% higher metal output over the crucible life. This was due to better erosion resistance provided by ResCoat which led to higher crucible life. Picture 1...

Open the catalog to page 2All Morgan Molten Metal Systems catalogs and technical brochures

-

Morganite® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Alustar E50

2 Pages

-

Z2e² PRO Coating

2 Pages

-

Degassing Rotors

2 Pages

-

Syncarb Z2 e2

1 Pages

-

Ladle Liners

2 Pages

-

Stabil

2 Pages

-

Grafit

2 Pages

-

Excel & Himelt

8 Pages

Archived catalogs

-

Morgan MMS Furnace Range

4 Pages

-

Crucible Lifter

2 Pages

-

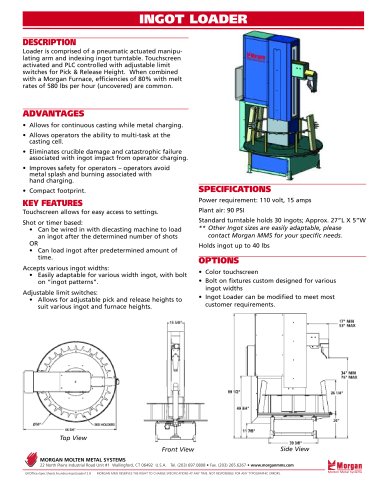

Ingot Loader

1 Pages

-

Foundry Products

2 Pages

-

Ultramelt Crucible Brochure

6 Pages

-

Crucible Accessories

4 Pages

-

Excel HiMelt Brochure

6 Pages

-

IsoAlustar Crucible Brochure

6 Pages

-

Salamander Crucible Brochure

4 Pages

-

Ultramelt Crucible Brochure

4 Pages

-

Indux Crucible Brochure

4 Pages

-

Starrbide Crucible Brochure

6 Pages

-

Excel E Crucible Brochure

4 Pages