Catalog excerpts

Molten Metal Systems

Open the catalog to page 1

Advanced Thinking in Crucibles and Foundry Products Contents NOLTINA® Product Overview / NOLTINA® Produktübersicht ___________________________ 04 Metal casting temperature / Metallgießtemperatur ________ 05 NOLTINA® Heating recommendations / Aufheizempfehlungen ______________________________06 – 07 A ________________________________________________ 08 – 09 BG SF ________________________________________________ 09 BN & NO _____________________________________________ 10 BU & NO ________________________________________ 11 – 12 C ____________________________________________________ 13 FU...

Open the catalog to page 2

NOLTINA® Product Overview / NOLTINA® Produktübersicht 1. GRAFIT • Rib-formed, clay-bonded crucible • Plastisch geformter, tongebundener Schmelztiegel • Variable electrical resistivity for induction furnaces • Variabler elektrischer Widerstand für Induktionsöfen • Very good chemical attack resistance • Sehr gute chemische Resistenz gegenüber Schmelzpräparaten • Very good thermal shock resistance • Sehr gute Temperaturwechselbeständigkeit • Isostatically pressed, clay-bonded crucible • Isostatisch gepresster, tongebundener Tiegel • Outstanding oxidation resistance • Hervorragende...

Open the catalog to page 4

Molten Metal Systems 5 Metal casting temperature / Metallgießtemperatur 1200˚C (2200˚F) Lead Bronze / Bleibronze Gun Metal / Rotguss Aluminium Bronze Cupronickel / Nickel Bronze Cast Iron / Gusseisen Aluminium Alloys / Aluminium Legierungen Syncarb VAluStar Silver / Silber Brass / Messing Zinc Distillation / Zink Destillation Copper / Kupfer Gold Bronze

Open the catalog to page 5

Heating recommendations for GRAFIT & SYNCARB Z2e² / FL / Z2 / VAluStar crucibles Aufheizempfehlungen für GRAFIT & SYNCARB Z2e² / FL / Z2 / VAluStar Schmelztiegel After installation in the furnace the crucible should be heated up slowly to a temperature of 200°C (390°F) over a period of 2 hours, in order to eliminate any moisture that may be present. Subsequently, the NOLTINA crucible should be heated up to 600°C (1100°F) on low power, before the full heating rate is used to reach 950°C (1750°F), or the desired working temperature if higher. Nach dem Einbau sollte der Tiegel innerhalb von 2...

Open the catalog to page 6

Molten Metal Systems 7 Heating recommendations for STABIL & SYNCARB UL / ISO-SiC R crucibles Aufheizempfehlungen für STABIL & SYNCARB UL / ISO-SiC R Schmelztiegel After installation in the furnace, the crucible should be heated up slowly to a temperature of 200°C (390°F) over a period of 2 hours, to eliminate any moisture that may be present. Afterwards, the crucible should be heated up to a temperature of 950°C (1750°F) on full power if possible. NOLTINA crucibles used in a melting operation can be continuously heated up on full power until working temperature is reached. The crucible is...

Open the catalog to page 7

* With pouring Lip * Mit AuGentulle ** See under Bilge Shape ** Siehe unter Bilge Form

Open the catalog to page 8

Molten Metal Systems Shape / Form A AS SYNCARB H mm D/d mm Sizes A200 - AII00 without pouring lip GroGe A200 - AII00 ohne AuGentulle * also available with d = 630 mm or d = 760 mm * lieferbar mit d = 630 mm oder d = 760 mm ** also available in SYNCARB ** lieferbar in SYNCARB Dimensions are subject to manufacturing tolerances / Abmessungen unterliegen fertigungsbedingten Toleranzen

Open the catalog to page 9

Size / Size / GroRe GroRe BN & NO Formen verfugbar mit oder ohne Pyrome-tertasche (PT) / Pyrometerloch (PL) * nur mit Pyrometerloch lieferbar Bohrungstoleranz +/- 1,5 mm

Open the catalog to page 10

Molten Metal Systems For tilting furnaces these crucibles can be supplied with recess in bottom (VT) and cut-out (AE) for spout Standard AE: up to D = 615 AE = 30 x 80 mm (H x B in mm) from D = 775 AE = 60 x 120 mm (H x B in mm) Standard VT: 12 x 100 (H x D in mm) * available with pyrometer-pocket ** available with pyrometer-hole in wall Fur Kippofen mit Bodenvertiefung (VT) und Ausgusseinschnitt (AE) lieferbar Standard AE: bis zu D = 615 AE = 30 x 80 mm (H x B in mm) ab D = 775AE = 60 x 120 mm (H x B in mm) Standard VT: 12 x 100 (H x D in mm) * lieferbar mit Pyrometertasche ** lieferbar...

Open the catalog to page 11

Shape / Form BU & NO BU Size / GroRe Size / GroRe BUS & NOS SYNCARB PL For tilting furnaces these crucibles can be supplied with recess in (VT) and cut-out (AE) for spout Standard AE: up to D = 615 AE = 30 x 80 mm (H x B in mm) from D = 775 AE = 60 x 120 mm (H x B in mm) Standard VT: 12 x 100 (H x D in mm) * available with pyrometer-pocket ** available with pyrometer-hole in wall bottom Fur Kippofen mit Bodenvertiefung (VT) und Ausgusseinschnitt (AE) lieferbar Standard AE: bis zu D = 615 AE = 30 x 80 mm (H x B in mm) ab D = 775 AE = 60 x 120 mm (H x B in mm) Standard VT: 12 x 100 (H x D in...

Open the catalog to page 12

Molten Metal Systems Up to size C 80 without recess in bottom * Without pouring lip Bis GroRe C 80 ohne Bodenvertiefung * Ohne AuRentulle Cut-out (AE) up to D = 6I5: 40 x 80 (H x D in mm) Bottom recess (VT): 12 x 100 (H x D in mm) Ausgusseinschnitt (AE) bis D = 6I5: 40 x 80 (H x D in mm) Bodenvertiefung (VT): 12 x 100 (H x D in mm) Dimensions are subject to manufacturing tolerances / Abmessungen unterliegen fertigungsbedingten Toleranzen

Open the catalog to page 13

Shape / Form P (TP without spout / TP ohne Ausguss) P PG GRAFIT Bottom recess (VT): 12 x 100 (H x D in mm) Bodenvertiefung (VT): 12 x 100 (H x D in mm)

Open the catalog to page 14

Molten Metal Systems Shape / Form R R Size / H Retorts / Retorten RETORT Dimensions are subject to manufacturing tolerances / Abmessungen unterliegen fertigungsbedingten Toleranzen

Open the catalog to page 15

Shape / Form TP (BU with Spout / BU mit Ausguss) Crucibles for heated transport ladles - Type 1 Tiegel fur beheizbare Transportpfannen - Typ 1

Open the catalog to page 16

Molten Metal Systems Shape / Form TPG SF2 TPG SF 2 Size / H h Crucibles for heated transport ladles - Type 2 Tiegel fur beheizbare Transportpfannen - Typ 2 Shape / Form US BASIN BASIN Dimensions are subject to manufacturing tolerances / Abmessungen unterliegen fertigungsbedingten Toleranzen

Open the catalog to page 17All Morgan Molten Metal Systems catalogs and technical brochures

-

Morganite® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Alustar E50

2 Pages

-

ResCoat Coating

2 Pages

-

Z2e² PRO Coating

2 Pages

-

Degassing Rotors

2 Pages

-

Syncarb Z2 e2

1 Pages

-

Ladle Liners

2 Pages

-

Stabil

2 Pages

-

Grafit

2 Pages

-

Excel & Himelt

8 Pages

Archived catalogs

-

Morgan MMS Furnace Range

4 Pages

-

Crucible Lifter

2 Pages

-

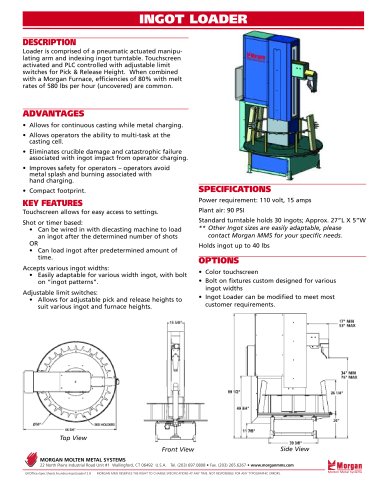

Ingot Loader

1 Pages

-

Foundry Products

2 Pages

-

Ultramelt Crucible Brochure

6 Pages

-

Crucible Accessories

4 Pages

-

Excel HiMelt Brochure

6 Pages

-

IsoAlustar Crucible Brochure

6 Pages

-

Salamander Crucible Brochure

4 Pages

-

Ultramelt Crucible Brochure

4 Pages

-

Indux Crucible Brochure

4 Pages

-

Starrbide Crucible Brochure

6 Pages

-

Excel E Crucible Brochure

4 Pages