Catalog excerpts

Innovating tomorrow's solutions... today SALAMANDER LADLE LINERS ✓ CLEAN, GAS FREE METAL ✓ LONG LIFE, NO PATCHING The liner should be set in the steel shell with Trimor Insulcast, which is a good insulator and sets firmly. Mix only sufficient for the job at hand Mix with water - four parts by weight of Insulcast, to one part 1. Ladle shells should be vented to ensure the release of moisture from the Insulcast. Shells with a capacity less than 150 Kg should have four 6mm holes in the base (Including one in the centre) and four around the side, well-spaced out. Shells with a capacity above 150Kg should have five 6mm holes in the base and six around the side. 2. The setting material should be vented using two lengths of string or"spun yarn" tied vertically around the lin- ers so as to make four vents, or for liners over 150 Kg capacity, three lengths to make six vents. 1. Place a thick layer of Insulcast in the bottom of the 2. Bed the liner down firmly, squeezing the setting material up the sides until the liner is level with the bottom of 3. Ram more Insulcast down from the top all around, so that the liner is firmly supported. The liner will rise during ramming, and should finish up 3 - 6mm above the Salamander Liner setting 3-6mm proud of steel shell String vents Cement seal around spouts Ladle Liner String vents Steel shell ASSEMBLY OF SALAMANDER LINERS IN STEEL LADLES 1. The refractory materials should be allowed to air-set over night. 2. Dry thoroughly for several hours, by torch or in an 3. Seal the joint between ladle and liner around the pouring spouts only, with 12mm depth of Salamander Morcem 900 mixed with water to a putty consistency. Do not 4. Thoroughly pre-heat cold ladles, as usual, It is dangerous to pour molten metal into a newly lined ladle, which has not been properly dried. New ladles should not be filled until all emission of steam has ceased and the liner should be sufficiently hot to char a piece MorganMMS is a business within the MEM Division of The Morgan Crucible Company pic.

Open the catalog to page 1

Salamander Super clay graphite ladle liners are available in the following sizes and can also be supplied with bottom pour arrangement (riser tube and cover plate). Salamander Clay Graphite Brimful Capacity (Litres) With riser tube and cover plate The following sizes are available as Excel silicon carbide ladle liners and also with bottom pour arrangement (riser tube and cover plate). With riser tube Salamander Excel Silicon Carbide Brimful Capacity (Litres) Notes 1. Pattern L, LB & LT are Salamander Super clay graphite 2. Pattern LX, LBX & LTX are Salamander Excel carbon bonded silicon...

Open the catalog to page 2All Morgan Molten Metal Systems catalogs and technical brochures

-

Morganite® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

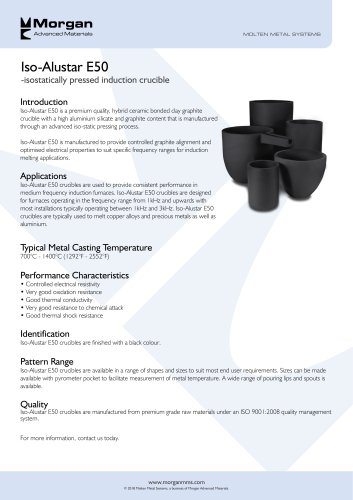

Alustar E50

2 Pages

-

ResCoat Coating

2 Pages

-

Z2e² PRO Coating

2 Pages

-

Degassing Rotors

2 Pages

-

Syncarb Z2 e2

1 Pages

-

Stabil

2 Pages

-

Grafit

2 Pages

-

Excel & Himelt

8 Pages

Archived catalogs

-

Morgan MMS Furnace Range

4 Pages

-

Crucible Lifter

2 Pages

-

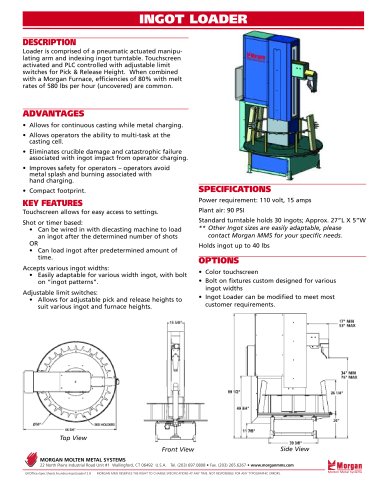

Ingot Loader

1 Pages

-

Foundry Products

2 Pages

-

Ultramelt Crucible Brochure

6 Pages

-

Crucible Accessories

4 Pages

-

Excel HiMelt Brochure

6 Pages

-

IsoAlustar Crucible Brochure

6 Pages

-

Salamander Crucible Brochure

4 Pages

-

Ultramelt Crucible Brochure

4 Pages

-

Indux Crucible Brochure

4 Pages

-

Starrbide Crucible Brochure

6 Pages

-

Excel E Crucible Brochure

4 Pages