Catalog excerpts

Innovating tomorrow’s solutions . . . today GRAFIT Crucibles DESCRIPTION Noltina‘s Grafit crucibles are rib formed CLAY-GRAPHITE crucibles characterised by high refractoriness and good thermal conductivity as well as very good thermal shock resistance and chemical resistance against fluxes. In order to meet the specific requirements of induction furnaces, NOLTINA has developed a specialised range of CLAY-GRAPHITE crucibles with a specific modified electrical resistivity. This optimises the coupling power of the crucibles especially in middle frequency induction furnaces (Frequence 1 kHz - 3 kHz) and avoids the risk of overheating. APPLICATIONS Noltina‘s Grafit crucibles are suitable for all furnace systems for non-ferrous metal alloys and precious metals with melting temperatures between 400°C and 1400°C. TYPICAL METAL CASTING TEMPERATURE 400 - 1400°C (752 - 2552°F) PERFORMANCE CHARACTERISTICS • • • • • High mechanical strength. Good thermal conductivity. Good resistance to chemical corrosion. High refractoriness. Good oxidation resisistance. IDENTIFICATION Noltina‘s Grafit crucibles are coloured black and utilize the suffix G to denote the type. PATTERN RANGE Noltina‘s Grafit crucibles are available in a wide range of sizes and shapes. Consult the product selector or contact MorganMMS for a specific recommendation based on your requirements. QUALITY Noltina‘s Grafit crucibles are manufactured from premium grade raw materials under an ISO 9001:2008 quality management system. MorganMMS is a business within the MEM Division of The Morgan Crucible Company plc. INSTALLATION Grafit crucibles are used free standing in lift out furnaces. In fuel fired and electric furnaces the stand should be made from similar material to the crucible to ensure uniform heating of the crucible base and provide sufficient mechanical support. The diameter of the stand should be at least the same as the base of the crucible and the height should be such that the base of the crucible is level with the centre line of the burner. The stand and crucible should be installed centrally in the furnace. In induction furnaces the crucible stands on a refractory pedestal and must be installed centrally within the coil. A thin layer of coke dust or other carbonaceous material should be sprinkled on to the stand or pedestal to prevent the crucible sticking to it. PREHEATING / FIRST USE Fuel-Fired and Electric Resistance Furnaces: A new crucible should be pre-heated empty in order to minimise the temperature gradient across the crucible wall. If the furnace refractories have been repaired or if there is a risk of the crucible having absorbed some moisture, then the furnace should initially be heated slowly up to circa 200ºC and held at this temperature until all moisture has been driven off. A new crucible should initially be heated slowly and evenly to 600ºC on low power (avoiding local impingement of flame for gas/oil fired furnaces). Subsequently the full heat input rate should be utilised to achieve a uniform bright red condition over the whole crucible (circa 900ºC / 1650ºF) at which point the crucible should be charged immediately taking care to avoid packing metal tightly or bridging ingots across the crucible. The furnace controls can then be set to achieve the desired metal operating temperature and heating should continue at the full rate until the metal has reached the desired temperature.

Open the catalog to page 1

In the case of crucibles to be fed with molten metal, it is important that the crucible body temperature is equivalent to or slightly above that of the molten metal in order to mini- mise thermal stress. Induction Furnaces: Grafit crucibles are sometimes used in medium to high frequency induction furnaces.The heat-up procedure is dependent on furnace frequency, coil dimen- sions, and the resistivity of the metal being melted. It is recommended where possible to preheat the crucible empty. The furnace should initially be run at 20% of maximum power until the crucible shows signs of red heat....

Open the catalog to page 2All Morgan Molten Metal Systems catalogs and technical brochures

-

Morganite® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Alustar E50

2 Pages

-

ResCoat Coating

2 Pages

-

Z2e² PRO Coating

2 Pages

-

Degassing Rotors

2 Pages

-

Syncarb Z2 e2

1 Pages

-

Ladle Liners

2 Pages

-

Stabil

2 Pages

-

Excel & Himelt

8 Pages

Archived catalogs

-

Morgan MMS Furnace Range

4 Pages

-

Crucible Lifter

2 Pages

-

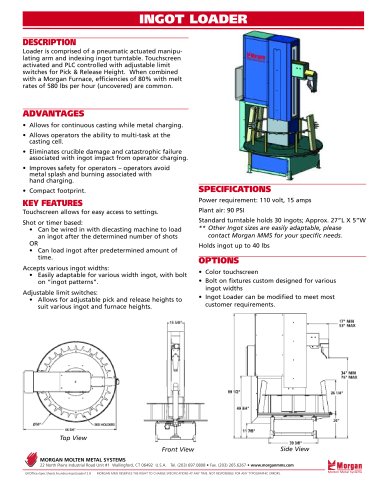

Ingot Loader

1 Pages

-

Foundry Products

2 Pages

-

Ultramelt Crucible Brochure

6 Pages

-

Crucible Accessories

4 Pages

-

Excel HiMelt Brochure

6 Pages

-

IsoAlustar Crucible Brochure

6 Pages

-

Salamander Crucible Brochure

4 Pages

-

Ultramelt Crucible Brochure

4 Pages

-

Indux Crucible Brochure

4 Pages

-

Starrbide Crucible Brochure

6 Pages

-

Excel E Crucible Brochure

4 Pages