Catalog excerpts

EXCEL and HIMELT are high quality carbon-bonded silicon carbidecrucibles manufactured using the latest roller-forming techniques and are designed to cater for a range of non-ferrous melting applications. > EXCEL: Intended for aluminium melting in oil-fired furnaces, meltingcopper-based alloys in gas and oil-fired furnaces, melting precious metals and non-ferrous alloys in low to medium frequency induction furnaces. HIMELT: Provides enhanced performance in those applications wheremore arduous service conditions exist. > Fast melting speed through high consistent thermal conductivityՕExcellent thermal shock resistance High resistance to oxidation ՕGood erosion resistance Good resistance to corrosive attack by chemical treatment agents INDUCTION FURNACES: The heat-up procedureisdependant on furnacefrequency,coil dimensions, and the resistivity of the metal being melted. It is recommended wherepossible to preheat the crucible empty.The power input rate should initially be limited until the crucible becomes bright red over its entiresurface. The time taken to pre-heat will depend on the size of the crucible, but is usually in the range 20 Ֆ 40 minutes. Once one thirdof the crucible is full of molten metal the power can be increased to a higher level. Silicon carbide crucibles absorbproportionally high levels of power from the induction field. Care should be taken not to overheat the crucible. The actual maximum power setting should be assessed from experience and will be dependant on the capacity of the crucible. The appearance of the inside wall of thecrucible should be monitored for signs of over-heating and the powerreduced once the full charge is molten. > FUEL-FIRED FURNACES: Crucibles should be pre-heated empty until theyreach a uniform bright red colour (circa 900C) in order to pre-condition the glaze. The pre-heating time will depend on the size of the crucible. In the case of large capacity crucibles and furnaces with high output burners the rate of temperature rise should be controlled in the initial stages to minimise thermal stress. The typical time taken from ambient to red heat is up to 1 hour. Avoid direct flame impingement on the crucible surface. EXCEL crucibles are coloured dark red and utilise the code X. e.g. AX800.HIMELTcrucibles arebright red and utilise the code HM e.g. AHM800. > EXCEL and HIMELT crucibles are available in a comprehensive range of shapes and sizes to suit most end user requirements. Custom sizes can be supplied by special request. Heavy wall (HW) versions can be supplied for increased life in arduous applications and a selection of fixed pouring spouts with optimised profiles is offered where required. EXCEL and HIMELT crucibles can be supplied with MorganiteВs unique PD coating system, which can assist with metal cleanliness and prevention ofdross adhesion. > EXCEL and HIMELT crucibles are manufactured from premium grade raw materials to ISO9000:2000 quality standards. > Crucibles should be cleaned out carefully between melts or at least once per day in holding applications while hot in order to remove build-up of oxide dross. In tilting furnaces crucibles should be cleaned in the horizontal position where possible. > As soon as the crucible has been pre-heated as specified, charge and melt immediately. Charge light scrap and returns first in order to form a cushion for heavier material. Use tongs to charge ingots and place large pieces and ingots vertically allowing space for expansion. Only add flux once the metal is molten and use the minimum quantity required to obtain good metal quality. > Proper safety clothing must be worn at all times. Ensure that no moisture is introduced into the melt. Provision should be made underneath the furnace to catch metal that may be discharged. > EXCEL,HIMELT EXCEL E INDUX SALAMANDER SUPER SYNCARB ULTRAMELT Roller-Formed SIC Roller-Formed SIC Clay Graphite Clay Graphite ISO-Pressed Clay Graphite ISO-Pressed SIC MORGAN MMS RESERVES THE RIGHT TO CHANGE SPECS AT ANY TIME. NOT RESPONSIBLE FOR ANY TYPOGRAPHIC ERRORS. size="-2">

Open the catalog to page 1

The stand should be made from the same material as the crucible toensure uniform heating of the crucible base and provide sufficient mechanical support. The diameter of the stand should be at least the same as the base of the crucible and the height should be such that the base of the crucible is level with the centre line of the burner in fuel-fired furnaces. The stand and crucible should be installed centrally in the furnace. Cement the stand on the floor of the furnace and ensure that it is central and level. Place the crucible centrally on the stand and use a thin layer of Morcem 900...

Open the catalog to page 6All Morgan Molten Metal Systems catalogs and technical brochures

-

Morganite® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

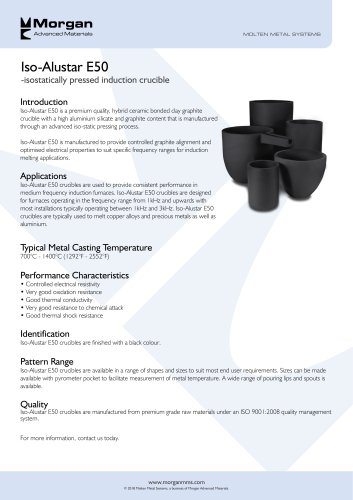

Alustar E50

2 Pages

-

ResCoat Coating

2 Pages

-

Z2e² PRO Coating

2 Pages

-

Degassing Rotors

2 Pages

-

Syncarb Z2 e2

1 Pages

-

Ladle Liners

2 Pages

-

Stabil

2 Pages

-

Grafit

2 Pages

-

Excel & Himelt

8 Pages

Archived catalogs

-

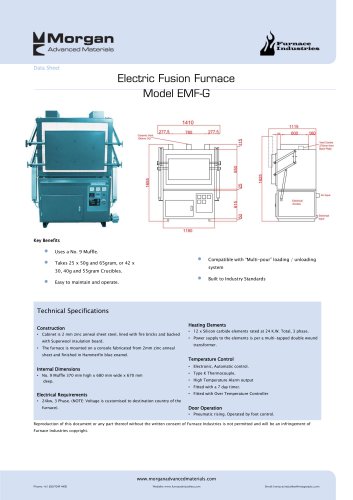

Morgan MMS Furnace Range

4 Pages

-

Crucible Lifter

2 Pages

-

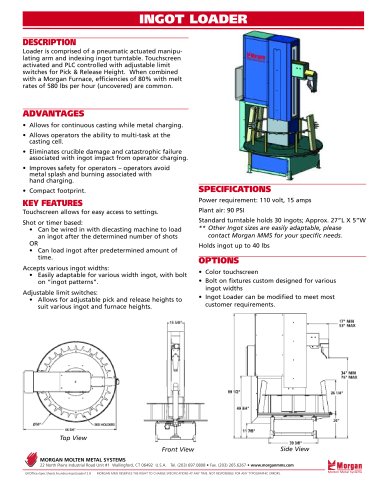

Ingot Loader

1 Pages

-

Foundry Products

2 Pages

-

Ultramelt Crucible Brochure

6 Pages

-

Crucible Accessories

4 Pages

-

IsoAlustar Crucible Brochure

6 Pages

-

Salamander Crucible Brochure

4 Pages

-

Ultramelt Crucible Brochure

4 Pages

-

Indux Crucible Brochure

4 Pages

-

Starrbide Crucible Brochure

6 Pages

-

Excel E Crucible Brochure

4 Pages