Catalog excerpts

MOLTEN METAL SYSTEMS Product name: DGRU I 50-700-S02T2 Application: Aluminum sand casting & permanent mold casting Casting parts: A wide range of cast parts, Furnace: Electric resistance Alloy: AlSiI0Mg - Aluminium Alloy Process duration: 5 minutes less crucible change overs consistent density index value For more details, please refer to page 2. www.morganmms.com © 2018 Molten Metal Systems, a business of Morgan Advanced Materials.

Open the catalog to page 1

MOLTEN METAL SYSTEMS Existing Rotor The customer was not happy about the short lifespan of existing degassing rotor (approximately 1 day). The rotor lifespan had reduced over the years to only 100 treatment cycles. The customer was eager to save costs of degassing without compromising the quality and efficiency of degassing process. The customer was delighted after using Morgan DGR for 1700 cycles without any significant change in density index. The rotor remained intact as shown in the photo. Picture 1 Existing Rotor after 100 treatment cycles. Picture 2 DGRU 150-700-S02T2 after 1700...

Open the catalog to page 2All Morgan Molten Metal Systems catalogs and technical brochures

-

Morganite® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

Noltina® Crucibles

32 Pages

-

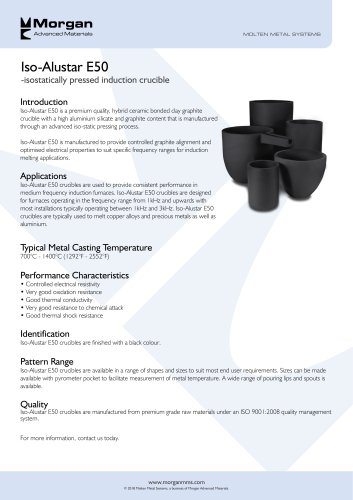

Alustar E50

2 Pages

-

ResCoat Coating

2 Pages

-

Z2e² PRO Coating

2 Pages

-

Syncarb Z2 e2

1 Pages

-

Ladle Liners

2 Pages

-

Stabil

2 Pages

-

Grafit

2 Pages

-

Excel & Himelt

8 Pages

Archived catalogs

-

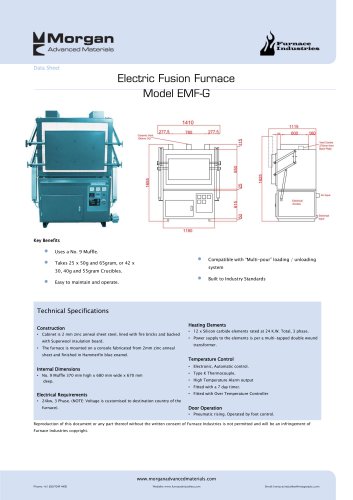

Morgan MMS Furnace Range

4 Pages

-

Crucible Lifter

2 Pages

-

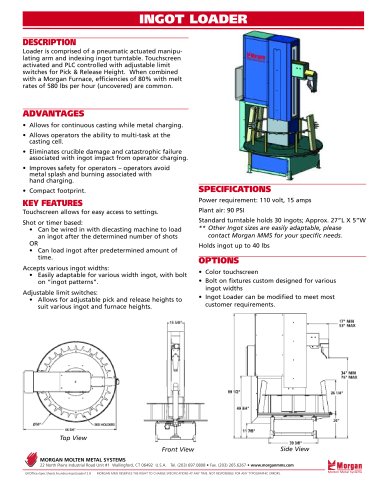

Ingot Loader

1 Pages

-

Foundry Products

2 Pages

-

Ultramelt Crucible Brochure

6 Pages

-

Crucible Accessories

4 Pages

-

Excel HiMelt Brochure

6 Pages

-

IsoAlustar Crucible Brochure

6 Pages

-

Salamander Crucible Brochure

4 Pages

-

Ultramelt Crucible Brochure

4 Pages

-

Indux Crucible Brochure

4 Pages

-

Starrbide Crucible Brochure

6 Pages

-

Excel E Crucible Brochure

4 Pages