Catalog excerpts

MORBARK 640 LOG DEBARKER B EN E F I TS • Multi purpose debarker that can be utilized in chip plants and sawmills and will accept soft woods, hardwoos, small and large logs. • Front and back yoke assemblies are adjustable, allowing the operator to properly center either large or small diameter sawlogs on the center of the cutterhead. • The hydraulic system has been engineered with proper reliefs to reduce or eliminate shock load to all working parts of the machine helping to keep downtime and maintenance costs to a minimum. The trough-type infeed and outfeed conveyors are variable in length up to 80’. The all steel infeed conveyor is fabricated from 5/8” formed plate steel with 3/8” gussets is equipped with Morbark’s exclusive all-steel welded track type chain Note: Specifications may vary with equipment options 25’ trough-type infeed conveyor with track type chain and hydraulic drive 25’ trough-type outfeed conveyor with WD-110 chain, hydraulic drive and one set of manually operated 3-arm kickers Front yoke set at 10o Hydraulic shoe for bark removal depth Hydraulic top wheel and back wheel adjustable to log diameter Hydraulic spiral control for debarking speed Table lock assembly Longer or shorter infeed with 13” track type chain Longer or shorter outfeed with WD-110 chain 25’ trough outfeed conveyor with 19” track type chain in lieu of standard 25’ trough infeed conveyor with 19” track type chain in lieu of standard Longer or shorter infeed and outfeed conveyors with 19” track chain 10,000 Series conveyor drive in lieu of standard 13” x 3/4” UHMW Duralite wear strip for infeed and outfeed conveyors 19” x 3/4” UHMW Duralite wear strip for infeed and outfeed conveyors Hydraulic oil temperature and level control Hydraulic oil tank heater All weather operator’s cab. Cab is 54” wide x 58” x long x 6’8”tall and includes two side sliding windows for cross ventilation Side mounted combination air conditioner/heater unit for cab enclosure Heavy duty underneath bark auger Hoses are provided to position operator’s console approximately 4’ from the debarker center section. Cab positions requiring longer hoses.

Open the catalog to page 1All Morbark catalogs and technical brochures

-

1300B TUB GRINDER

2 Pages

-

1600 TUB GRINDER

2 Pages

-

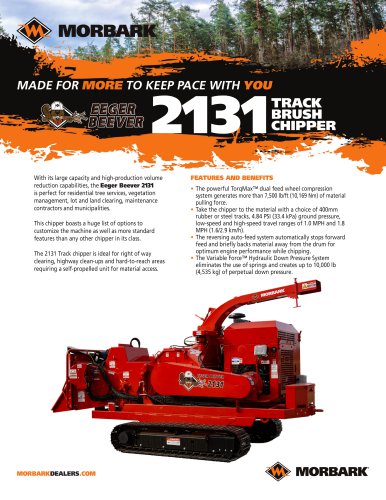

2131

2 Pages

-

RUSH CHIPPERS

22 Pages

-

23X series

1 Pages

-

MORBARK® 50/48X

1 Pages

-

640 Debarker

1 Pages

-

DeNubber Debarking Head

1 Pages

-

C Series Debarker

1 Pages

-

PSP Pole and Post Peeler

1 Pages

-

48″ & 58″ Chip Pacs

1 Pages

-

1300 VMill

1 Pages

-

Trough-Type Conveyor

1 Pages

-

Stac-Trac 1000

1 Pages

-

Green Chains

1 Pages

-

Mulch Hog

1 Pages

-

40/36 NCL WHOLE TREE CHIPPER

1 Pages

-

30-36B WCL

1 Pages

-

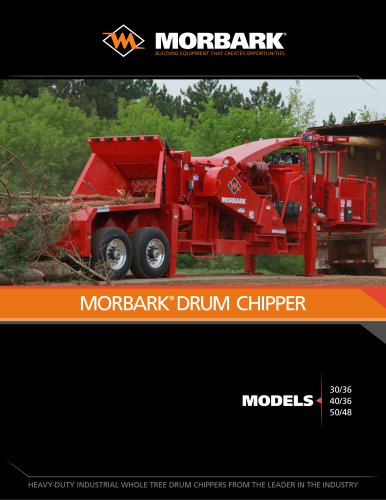

MORBARK ® DRUM CHIPPER

6 Pages

-

Morbark Beever M12R

1 Pages

-

Morbark Beever M12D

1 Pages

-

Morbark Beever M8D

1 Pages

-

Morbark Beever M6R

1 Pages

-

D76 track stump grinder

1 Pages

-

D86 track stump grinder

1 Pages

-

CHIP SCREENS

1 Pages

-

CHIP-PACS

1 Pages

-

C-SERIES DEBARKERS

1 Pages

-

PS8 POST PEELER

1 Pages

-

1300 V-MILL

1 Pages

-

through type conveyor

1 Pages

-

MATERIAL HANDLING CONVEYOR

1 Pages

-

BARN SWEEP CONVEYOR

1 Pages

-

1000 . STAC . TRAC

1 Pages

-

LIVE DECKS

1 Pages

-

CHIP BLOWERS

1 Pages

-

CIRCULAR CHOP SAW

1 Pages

-

MORBARK GREEN CHAIN

1 Pages

-

MODEL . HD-30 . MULCH . HOG

1 Pages

-

MORBARK® BEEVER™

6 Pages

-

1200XL Tub Grinder

1 Pages

-

Vibrating Conveyors

1 Pages

-

Stationary Chippers

1 Pages

-

628 Debarker

1 Pages

-

20 NCL Chiparvestor

1 Pages

-

2355 Flail Chiparvestor

1 Pages

-

5500 Stand-Alone Flail

1 Pages

-

25/36 NCL Drum Chipper

1 Pages

-

4600XL Wood Hog

1 Pages

-

D52SPH Stump Grinder

1 Pages

-

7600B Wood Hog

1 Pages

Archived catalogs

-

1300B Tub Grinder

1 Pages

-

Morbark Beever M6R

1 Pages

-

Entire Sawmill Product Guide

20 Pages

-

Predator Shredder

1 Pages

-

Electric Powered Units

3 Pages

-

1600 Tub Grinder

1 Pages