Website:

Morbark, Inc.

Website:

Morbark, Inc.

Catalog excerpts

Infeed chute attaches to impact hopper and directs material to hammermill rotor. Chute is constructed from 1/4” thick sides and 1/2” thick top and back. Standard chute opening for infeed conveyor is 50 1/2” wide and 43 15/16” high and includes a double debris curtain for material containment. Must specify infeed material size. OUTFEED OPTIONS • Discharge chute back and sides are constructed from 1/4” thick T1 steel. Rubber seals around bottom of chute help contain material flow on to optional outfeed conveyor. (specify direction of discharge). • Outfeed Trough Type Belt Discharge Conveyor, 60” wide x 22’ long, complete with three (3) troughing rolls and three (3) idler rolls. Head and tail pulley (self-cleaning) are 12” diameter with 2-7/16” shafts. 5-HP electric drive with gear reduction drive. Conveyor mounts underneath Hammermill. • Longer or shorter outfeed belt conveyor per foot. • 2,000 Series Char-Lynn Hydraulic Drive in lieu of standard for the discharge conveyor (less power source). • Magnetized End Pulley, for discharge conveyor, complete with collecting slide tray for ferrous metal removal. STANDARD EQUIPMENT 31” x 55” hammermill system constructed of heavy duty 20” diameter rotor, (13) 1-7/8” (2 piece) thick laser-cut rotor plates to ensure precision and enforce steel strength. The plates are keyed on a 7” diameter shaft with 4-7/16” bearings and (8) 2-1/4” hammer retaining rods. Complete with (24) 2” balanced steel fixed teeth insert hammers and (24) 2-1/2” wide double-edged replaceable teeth inserts. One set of two (2), 5” hexagon x 1” thick wear form steel heavy duty grates Hammermill base with grate supports. Impact hopper is constructed of 1/2” steel. Hopper has AR plate bolt on wear plates. Hopper is hinged for easy access to Hammermill and grates. Two hydraulic cylinders with safety lockouts operate Hopper tilt. 110-volt power pack to open hopper is furnished when no hydraulic pump stand is ordered. The frame supporting the hammermill is made of 12” x 8” structural tubing and is 8’7” wide and 17’6” long [14’ 9” on single engine frame]. Surface is covered with floor grating. Motor rails Leg Package includes (6) legs, (2) sets of stairs, 3’ wide catwalk on both sides of platform and handrails. Catwalks and handrails removed for transporting. With catwalks attached, overall size of platform is 14’7” wide x 17’6” long. Standard legs give platform an overall height of 84” high Longer legs

Open the catalog to page 1All Morbark catalogs and technical brochures

-

1300B TUB GRINDER

2 Pages

-

1600 TUB GRINDER

2 Pages

-

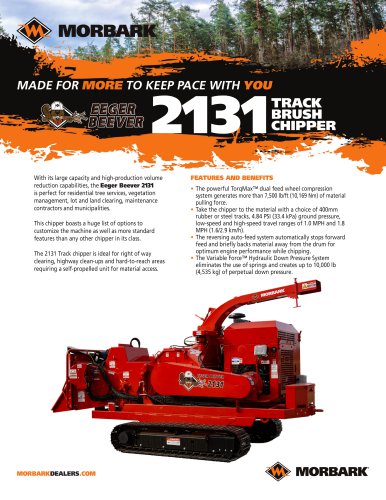

2131

2 Pages

-

RUSH CHIPPERS

22 Pages

-

23X series

1 Pages

-

MORBARK® 50/48X

1 Pages

-

640 Debarker

1 Pages

-

DeNubber Debarking Head

1 Pages

-

C Series Debarker

1 Pages

-

PSP Pole and Post Peeler

1 Pages

-

48″ & 58″ Chip Pacs

1 Pages

-

1300 VMill

1 Pages

-

Trough-Type Conveyor

1 Pages

-

Stac-Trac 1000

1 Pages

-

Green Chains

1 Pages

-

Mulch Hog

1 Pages

-

40/36 NCL WHOLE TREE CHIPPER

1 Pages

-

30-36B WCL

1 Pages

-

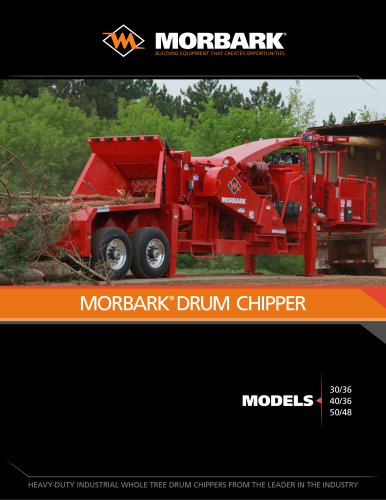

MORBARK ® DRUM CHIPPER

6 Pages

-

Morbark Beever M12R

1 Pages

-

Morbark Beever M12D

1 Pages

-

Morbark Beever M8D

1 Pages

-

Morbark Beever M6R

1 Pages

-

D76 track stump grinder

1 Pages

-

D86 track stump grinder

1 Pages

-

MORBARK 640 LOG DEBARKER

1 Pages

-

CHIP SCREENS

1 Pages

-

CHIP-PACS

1 Pages

-

C-SERIES DEBARKERS

1 Pages

-

PS8 POST PEELER

1 Pages

-

through type conveyor

1 Pages

-

MATERIAL HANDLING CONVEYOR

1 Pages

-

BARN SWEEP CONVEYOR

1 Pages

-

1000 . STAC . TRAC

1 Pages

-

LIVE DECKS

1 Pages

-

CHIP BLOWERS

1 Pages

-

CIRCULAR CHOP SAW

1 Pages

-

MORBARK GREEN CHAIN

1 Pages

-

MODEL . HD-30 . MULCH . HOG

1 Pages

-

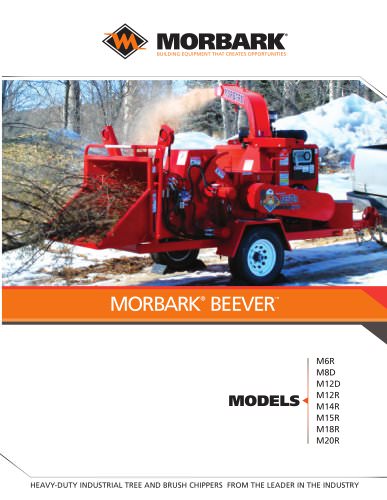

MORBARK® BEEVER™

6 Pages

-

1200XL Tub Grinder

1 Pages

-

Vibrating Conveyors

1 Pages

-

Stationary Chippers

1 Pages

-

628 Debarker

1 Pages

-

20 NCL Chiparvestor

1 Pages

-

2355 Flail Chiparvestor

1 Pages

-

5500 Stand-Alone Flail

1 Pages

-

25/36 NCL Drum Chipper

1 Pages

-

4600XL Wood Hog

1 Pages

-

D52SPH Stump Grinder

1 Pages

-

7600B Wood Hog

1 Pages

Archived catalogs

-

1300B Tub Grinder

1 Pages

-

Morbark Beever M6R

1 Pages

-

Entire Sawmill Product Guide

20 Pages

-

Predator Shredder

1 Pages

-

Electric Powered Units

3 Pages

-

1600 Tub Grinder

1 Pages