Catalog excerpts

November 2000 Data Sheet 5.11 The high-performance IPT > 2 Current-to-Pressure (I/P)Transmitter converts a current signal to a pneumatic signal so that an electronic-based system such as a DCS, PLC, or PC can control a pneumatic actuator, valve, or damper drive. Available models accept a wide range of current inputs (4-20mA, 4-12mA, and 12-20mA) and provide a proportional pneumatic signal (3-15psig, 0.2-1 Bar, 20-100kPA, etc.).The IPT > 2 is available in a compact, 40mm wide alumi-num housing that can be conveniently snapped onto a standard mounting rail or Moore Industries pneumatic header rack (such as the RIR and SIR, shown in Figure 4).Standard features that raise the IPT > The IPT 2 pneumatic mounting block allows the unit to beeasily snapped onto a DIN rail for high density installation. 2 above the compe-tition include a front panel LED that varies in intensity to reflect the strength of the input current and a built-in orifice cleaning mechanism that eliminates potentially messy clogs. Time-saving equipment such as a pneumatic test jack that simplifies calibration and maintenance is also available. > Wide variety of output and air supply choices. ?Enhanced circuit design. Choose one of 18 different standard output pressure ranges or contact the Interface Solution Center nearest you for custom ranges. Closed loop designdelivers quick response to step changes, enhances accuracy, and reduces drift. ?Low air consumption and high output volume. The IPT > Figure 1. A typical IPT 2 application. IPT Current-to-PressureTransmitter 2 2 outputs at least 2.0 SCFM whileconsuming just 0.08 SCFM. > 2 ?High accuracy. With an accuracy of ձ0.25% ofspan and a six-month stability rating, you can be confident that the IPT > IPT CURRENT/PRESSURETRANSMITTER +ININ SPANZERO 2 will provide you with anaccurate signal for a long time to come. > +T֖T ?Immune to supply pressure variation. The IPT > 2 CurrentSignal PneumaticControl Valve maintains its incredible accuracy even when thesupply pressure fluctuates between 20 and 40psi. ?Clog-resistant design. A larger orifice with anexternal plunger for cleaning the orifice, provides excellent protection against clogging. ?Clean start-up. A valuable feature in cold weatherconditions, an advanced mechanical assembly prevents stickingӔ upon instrument restart-up. ?RFI/EMI protection. Special circuit and housingdesigns protect against the harmful and unpredict- able effects of radio frequency and electromagnetic interference. > Certification CE Conformant EMC Directive 89/336/EECEN 50081-2, 1993 and EN 50082-2, 1995 ֩ 2000 Moore Industries-International, Inc. Page 1 size="-2">

Open the catalog to page 1

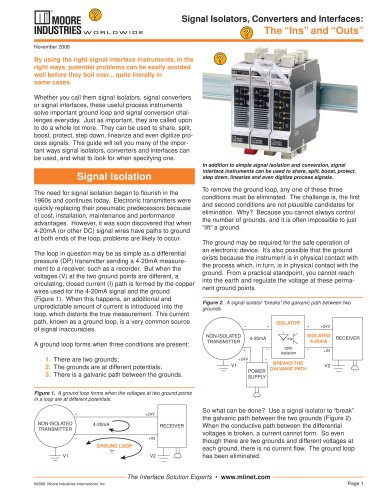

2 CURRENT/PRESSURETRANSMITTER +IN IN SPANZERO Span Adj. Air Vents Zero Adj. PneumaticTest Jack > +T֖T Orifice-CleaningPlunger MountingBlock > Rear Access Location for PneumaticConnections,1/8 NPT FRONT VIEW SIDE VIEW Bottom Access Location for PneumaticConnections,1/8 NPT Red LED "ON" When Input Current is PresentElectrical Test Jack (Calib.) For 2 mm (0.8 in) Dia. Phone Tip Plug 12mm(.45 in) >

Open the catalog to page 4All Moore Industries catalogs and technical brochures

-

SB

2 Pages

-

LH

2 Pages

-

TMZ

8 Pages

-

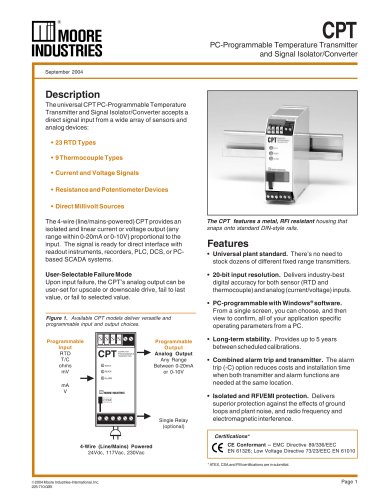

CPT (Current/Voltage Input)

8 Pages

-

CCS - Cable Concentrator System

12 Pages

-

HIM HART® Interface Module

8 Pages