Catalog excerpts

CHLORINATION/DECHLORINATION CONTROLLER Flow Pacing Control Residual Chlorine Control Compound Loop Chlorine Control Dechlorination Control The Interface Solution Experts www.miinet.com PS555 V5

Open the catalog to page 1

CHLORINATION/DECHLORINATION CONTROLLER Automatic and accurate control of chlorine in potable and waste water is more important than ever due to health and regulatory concerns. Poor control can lead to failure of biomonitoring tests leading to an even more costly "Toxicity Reduction Evaluation." The 555 is a cost-effective way to upgrade chlorination and dechlorination processes in an easy to use, rugged 1/4 DIN size package. The 555 can be easily set up to handle flow proportional control, residual control, compound loop control with lag times, and dechlorination with sulfur dioxide....

Open the catalog to page 2

FLOW PACING CHLORINE CONTROL Both chlorination and dechlorination may be accomplished simultaneously based on the same water flow rate. Ease of use is provided by continuous readout of dosage setting and flow rate or valve position. Flow paced control is well suited for applications where the water flow rate varies but the disinfection/ oxidation demand remains constant. Flow paced (or flow-proportioning) control positions a chlorine or sulfur dioxide valve in direct proportion to the water flow rate. For chlorine, a user-defined "dosage-setting" from 0% to 400% (the percentage of gas flow...

Open the catalog to page 3

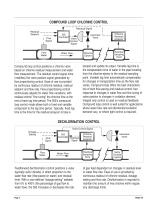

COMPOUND LOOP CHLORINE CONTROL l c sample and update its output. Variable lag time is the transportation time of water in the pipe traveling from the chlorine ejector to the residual sampling point. Variable lag time automatically compensates for changes in transportation time as the flow rate varies. Compound loop offers the best characteristics of both flow pacing and residual control: fast response to changes in water flow and fine tuning of valve position to changes in oxidation demand. Integral only control is used on residual feedback. Compound loop control is well suited for...

Open the catalog to page 4

SPECIFICATIONS ACCURACY PROCESS VARIABLE INPUTS TYPICAL Linear (Voltage) ± 0.025% of full scale ± 0.100% of full scale (Current) ± 0.050% of full scale ± 0.150% of full scale Display accuracy is ± 1 digit. These accuracy specifications are at reference conditions (25°C). Detailed accuracy information is available upon request. Two universal inputs are available. TRANSMITTER/ANALYZER SIGNALS Milliamps DC Voltage DC Millivolts DC CONTROL MODES Flow pacing The controller output is based on a selected chlorine, and or sulfur dioxide dosage (0-400%) which is proportional to a given flow rate....

Open the catalog to page 5

INPUT FILTER Single pole lowpass digital filter with selectable time constant from 0 to 120 seconds. CALIBRATION Continuous calibration compensates for component aging due to temperature and time, except for the reference voltage. Reference calibration can be easily performed in the field with only a precision multimeter. Process variable offset and gain factors are provided to correct for sensor errors. OUTPUT MODULES Up to four output modules may be installed. There are five types of output modules which can be mixed and matched to suit your particular application. The modules may be...

Open the catalog to page 6

Meets 1/4 DIN designation as specified in DIN standard number 43 700. See dimensional diagram below for details. MOUNTING Panel-mounted. See diagram for details. WIRING CONNECTIONS Case: extruded, non-perforated black anodized aluminum with ABS plastic sleeve. Bezel: black plastic ABS. Chassis assembly: plug-in type. Keys: silicone rubber with diffusion printed graphics. NEMA rating: front panel conforms to NEMA 4X when instrument is properly installed. 29 screw terminals in the rear of the instrument. AGENCY APPROVALS POWER CONSUMPTION LISTED Process Control Equipment Approximately 1 kg...

Open the catalog to page 7

ORDERING INFORMATION 555 OUTPUT 1 — CONTROL OUTPUT 2 — CONTROL, ALARM, OR RETRANSMISSION OUTPUT 4 — ALARM, RETRANSMISSION, OR LOOP POWER OPTIONAL INPUTS OUTPUT 3 — ALARM OR RETRANSMISSION SERIAL COMMUNICATIONS Capability for position proportioning output is specified by ordering 555-11xxAxxx00, 555-33xxAxxx00, or 555-44xxAxxx00. (Slidewire not required for velocity proportioning.) Note 2: Up to two outputs may be used for alarms. Note 3: All outputs are interchangeable modules. Note 4: The mechanical relay and solid state relay modules are derated to 0.5 amp at 24 Vac when used as the...

Open the catalog to page 8All Moore Industries catalogs and technical brochures

-

SB

2 Pages

-

LH

2 Pages

-

TMZ

8 Pages

-

CPT (Current/Voltage Input)

8 Pages

-

CCS - Cable Concentrator System

12 Pages

-

HIM HART® Interface Module

8 Pages