Website:

MONTECH

Website:

MONTECH

Catalog excerpts

more than technology

Open the catalog to page 1

CONVEYORS - OVERVIEW The Montech portfolio includes: – Conventional belt conveyors in different executions, with configurable lengths and widths; – SOLTB conveyors specifically designed for lightweight products, e.g. substrates for the photovoltaic industry; – Multitrack conveyors for large parts up to 120 kg; – Longitudinal transfer system with modular design, allowing the implementation of automation processes with a gradual approach; – Cleanroom conveyor with ISO 5 cleanroom certification for applications in the pharmaceutical and medical industry. All products leverage many years of...

Open the catalog to page 2

PRODUCT DESCRIPTION TECHNICAL DATA WORKPIECE CARRIER BELT SECTION DRIVE / DRIVE CONTROLLER SEPARATING UNIT POSITIONING UNIT PLACING UNIT load of up to 16.8 kg and can be equipped with RFID so that LATERAL TRANSPORT they can be identified at any time. LIFTING/TURNING UNIT The individual transport sections will be equipped with the selected assemblies according to the customer's wishes. PLANNED ASSEMBLIES The LT40 transport system consists of a dual-belt system on which the individual workpiece carriers run at a speed of up to 20 m/min. The workpiece carriers in six sizes allow a rated Thanks...

Open the catalog to page 3

TRANSPORT SYSTEM LT40 - PRODUCT DESCRIPTION The closed aluminum chassis profile without profile grooves provides optimum stiffness at a low weight. The separating unit stops the workpiece carriers at the desired location. The 90° deflection is used for redirection. Workpiece carriers can be removed with the lateral transport or with a switchable transfer gate. Positioning and placing units are available for work on the workpiece carriers. The bridge lift unit makes decoupling from the line possible and is suitable for time-intensive processing. Workpiece carrier alignment within the line...

Open the catalog to page 4

TRANSPORT SYSTEM LT40 - PRODUCT DESCRIPTION Advantages of the LT40: – The almost noiseless drive with a diameter of only 60 mm is directly integrated into the shaft, giving it a compact build. With cable routing available as an accessory, the dovetail can be covered on the outside and/or inside. – Conveying speed, direction, acceleration and deceleration will be adjusted continuously over an open field bus (Profibus DP). – With the future Configurator, 3D CAD data and offers can be easily created at www.montech.com. – The system’s individual belt section will be designed and assembled by...

Open the catalog to page 5

TRANSPORT SYSTEM LT40 - TECHNICAL DATA Ambient temperature normal workshop atmosphere Noise level Protection class of components Repeatability Workpiece carrier sizes 200 ×200 mm (weight: 1180 g) 200 ×240 mm (weight: 1453 g) 240 ×240 mm (weight: 1772 g) 240 ×320 mm (weight: 2375 g) 320 ×320 mm (weight: 3245 g) 320 ×480 mm (weight: 4890 g) Max. pressure position unit Max. pressure placing unit Operating pressure Operating medium Material workpiece carrier 15 5–6 air, oiled or unoiled, filtered to 5 µm, dew point < 6 °C Polyethylene terephthalate PET, black Lateral guide material Belt type...

Open the catalog to page 6

WORKPIECE CARRIER WT - PRODUCT DESCRIPTION For the LT40, there are square and also oblong workpiece carriers in six different sizes: 200x200, 200x240, 240x240, 240x320, 320x320 and 320x480mm (width x length). The maximum rated loads range from 7 kg to 16.8 g depending on the workpiece carrier. Thanks to the solid plastic material, the workpiece carriers are over 4 times more rigid than comparable workpiece carriers from competitors (frame structures and metal filling) and lighter as well. Thanks to threaded inserts for M5 screws and center bores on the top of the workpiece carrier,...

Open the catalog to page 7

WORKPIECE CARRIER WT - DIMENSIONS Weight total

Open the catalog to page 8

WORKPIECE CARRIER WT - DIMENSIONS

Open the catalog to page 9

BELT SECTION BS40 WITH INTEGRATED DRIVE - PRODUCT DESCRIPTION LT40 uses belt sections with a dual-belt system. The length is variable up to 3000 mm in three sizes: 200 mm, 240 mm and 320 mm. There are also belt sections longitudinal (round tabs) and belt sections lateral (mounting tabs). The belt sections lateral can be mounted perpendicular to the belt sections longitudinal via the dovetail guide. Also available is a chassis width of 480 mm (for the lateral transport of the workpiece carrier 320 mm ×480 mm). The drive is built into the drive roller of only 60 mm diameter with no protruding...

Open the catalog to page 10

BELT SECTION LONGITUDINAL BS40 WITH INTEGRATED DRIVE - DIMENSIONS Belt section longitudinal Type 200 Belt section longitudinal Type 240 Belt section longitudinal Type 320

Open the catalog to page 11

BELT SECTION LATERAL BS40 WITH INTEGRATED DRIVE Belt section lateral Belt section lateral Belt section lateral Lateral belt section

Open the catalog to page 12

CALCULATING THE CHASSIS LENGTH, THE LATERAL GUIDE LENGTH FOR ALL DRIVES Belt section long/long L60/L60 76 38 Conveyor length LS = Lateral guide (max. 3000 mm) Exit Belt section lateral/lateral Q60/Q60 Conveyor length LC = L – 160 mm LS = Lateral guide (max. 3000 mm) Exit Belt section lateral/long Q60/L60 Conveyor length LC = Chassis length (max. 3000 mm) Incoming LC = L – 156 mm LS = Lateral guide (max. 3000 mm) Exit Belt section long/lateral L60/Q60 L= Conveyor length LS = Lateral guide (max. 3000 mm) LS = L – 156 mm LA = Axis distance

Open the catalog to page 13

CALCULATING BELT LENGTH Calculating the belt length LG = Belt length LC = Chassis length LG = 0.992[(2 × (LC+76))+(62 × π)] Belt thickness = 1.0 mm Pretension = 0.8 % Calculating the belt length deflection: (one side only) Belt length Weiche = LG+165 mm Belt thickness = 1.0 mm Pretension = 0.8 % Calculating the belt length cental drive: Belt length center drive = LG+178.5 mm Belt thickness = 1.0 mm Pretension = 0.8 % Belt type / quantity per chassis Belt width Belt length LT40/0200/01000/G2/0025/2354/OI/L60/L60 Conveyor length Conveying width Conveyor type End-outlet side End-inlet side...

Open the catalog to page 14

BELT SECTION BS40 - DRIVE By default, the integrated drive is used. The center drive is used when heavy masses are transported. Integrated drive Center drive Drive rated power cable length 500 mm with connector M16 CENTER DRIVE - DIMENSIONS 190 cable output Center drive

Open the catalog to page 15All MONTECH catalogs and technical brochures

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

Conveyor TB30

57 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

CONVEYOR TB30

57 Pages

-

RB40 Roller Conveyor

18 Pages

-

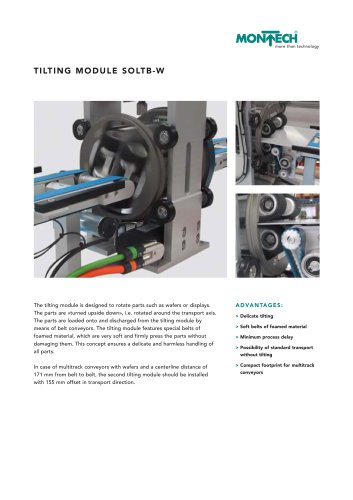

TILTING MODULE SOLTB-W�

2 Pages

-

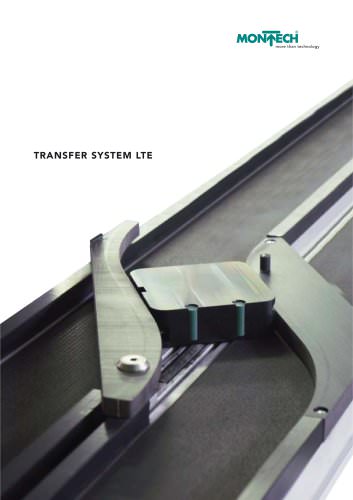

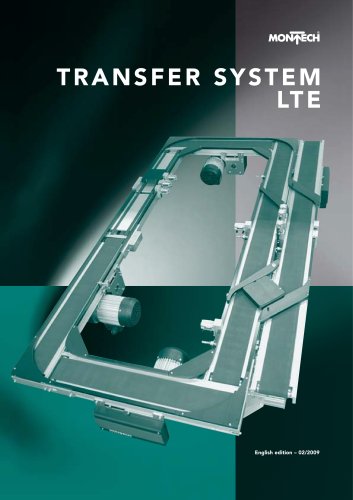

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

Automation – Accessories

6 Pages