Catalog excerpts

more than technology

Open the catalog to page 1

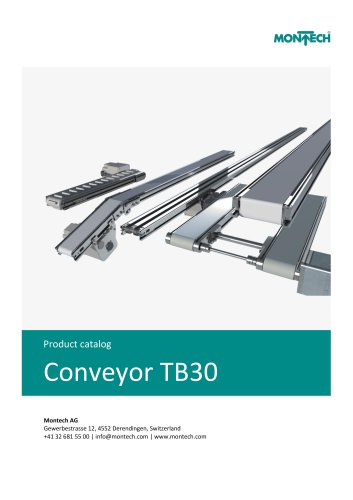

CONVEYORS - OVERVIEW The Montech portfolio includes: – Conventional belt conveyors in different executions, with configurable lengths and widths; – SOLTB conveyors specifically designed for lightweight products, e.g. substrates for the photovoltaic industry; – Multitrack Conveyors for big parts up to 120 kg; – Longitudinal transfer system with modular construction, allowing to implement automation processes with a gradual approach; – Cleanroom Conveyor with Class ISO 5 certification for applications in the pharmaceutical and medical industry. All products leverage many years of experience...

Open the catalog to page 2

PRODUCT DESCRIPTION TECHNICAL DATA CONVEYOR TB/TBD BYPASS CONVEYOR BPBE workpiece holders made of high-strength plastic and are The workpieces to be processed are attached to standardized CURVES KFE/KBEA ing to their asssembly sequence. CONVEYORS COMPONENTS guide workpieces through the necessary workstations accord- BELT FABRICATION nous transfer system whose function is to automatically The single-belt transfer system from Montech is an asynchro- BYPASS BPEA/BPE INDEXING DEVICE IVE/IVEB carried on single-belt conveyors. The modular system makes it possible to implement the automation...

Open the catalog to page 3

TRANSFER SYSTEM LTE - PRODUCT DESCRIPTION Typical application criteria are: • assembly automation and logistics • system arrangement «inline» and/or «offline» • repeatability ± 0.05 mm • four workpiece holders: 80 x 80, 115 x 115, 160 x 160 and 225 x 225 mm To ensure a high degree of flexibility, we recommend the use of the profile system Quick-Set as a substructure. It is based on a dovetail clamping principle, requires no drilling or pinning, and can be used universally.

Open the catalog to page 4

TRANSFER SYSTEM LTE - TECHNICAL DATA Ambient temperature normal workshop atmosphere Noise level type of switching nominal rating delta/star (factory state) [W] winding rated current with 3 temperature contacts [A] Workpiece holder WTE sizes 115 ×115 mm (weight: 360 g) 160 ×160 mm (weight: 690 g) 225 ×225 mm (weight: 1660 g) Max. weight WTE 80, 115, 160 (with load) Max. weight WTE 225 (with load) Operating pressure Operating medium Material workpiece holder WTE Material lateral guide Belt type (recommended) air, oiled or unoiled, filtered to 5 µm, dew point < 6 °C polyethyleneterephtalat...

Open the catalog to page 5

MAXIMUM TORQUE POSITIONING UNIT PVE

Open the catalog to page 6

TRANSFER SYSTEM LTE - TECHNICAL DATA Changeover times (with belt type ENI-5EE) Speed Indexing device IVE / IVEB IVE / IVEB-105 Movable curve with drive KBEA KBEA-105 Movable curve without drive KBE KBE-105 Bypass with drive BPEA Bypass without drive BPE BPE-105 Times indicated refer to the time for setting and setting back the curve with drive, or the transfer gate, or the bypass with drive, plus the transit time of the workpiece holder. For the curve and the bypass BPE without drive, the time indicated refer the time for setting and setting back plus the transit time of the workpiece holder.

Open the catalog to page 7

PRODUCT DESCRIPTION WORKPIECE HOLDER WTE The workpiece holder WTE made from high-strength plastic is available in four standard sizes: 80 × 80, 115 × 115, 160 × 160 and 225 × 225 mm. Depending on the design of the pallet transfer system and the preferred direction of transport, version A or mirrored version B is used. The permissible total weight of each workpiece holder, including workpiece receiver and product, is 2.5 kg.

Open the catalog to page 8

WORKPIECE HOLDER WTE - DIMENSIONS G

Open the catalog to page 9

WORKPIECE HOLDER WTE - DIMENSIONS

Open the catalog to page 10

CONVEYOR TB - PRODUCT DESCRIPTION The conveyor both modular and proven in design forms the basis of the transfer system. Chassis widths of 105, 140, 185 and 250 mm are used for the respective workpiece holders. The conveyors are driven by a 3 × 230/400 V central spur gear drive. Belt speeds can be varied simply and economically between 7.5 and 19.9 m/min using conversion kits. The construction is precise, stable and durable. All steel parts are nickel plated or made from non-corroding materials; deflecting rollers are stainless, and the drive rollers are coated with vulcanized rubber.

Open the catalog to page 11

CONVEYOR SINGLE-BELT WITH DRIVE HORIZONTAL TB - DIMENSIONS L max. 282 256 205 139 Link to Configurator Link to CAD Data Type horizontal drive min. 385 mm – max. 3 m (at certain conditions may even longer bands are allowed))

Open the catalog to page 12

CONVEYOR SINGLE-BELT WITH DRIVE VERTICAL TB - DIMENSIONS L 155.5 144 30 Link to Configurator Link to CAD Data Type vertical drive min. 324 mm – max. 3 m (at certain conditions may even longer bands are allowed))

Open the catalog to page 13

CONVEYOR DUAL-BELT WITH DRIVE HORIZONTAL TBD - DIMENSIONS L max. 282 256 205 Link to Configurator Link to CAD Data Type horizontal drive min. 385 mm – max. 3 m (at certain conditions may even longer bands are allowed))

Open the catalog to page 14

CONVEYOR DUAL-BELT WITH DRIVE VERTICAL TBD - DIMENSIONS L 155.5 144 30 Link to Configurator Link to CAD Data Type verticalal drive min. 324 mm – max. 3 m (at certain conditions may even longer bands are allowed))

Open the catalog to page 15

PRODUCT DESCRIPTION BYPASS CONVEYORS BPBE The bypass belt permits the installation of two parallel conveying sections with only one drive unit. The distance between the two conveyor belts is 12 mm. Consequently, the inward and outward transfer elements (see catalog, pages 37 to 39) can be installed in the bypass belt for construction of a bypass.

Open the catalog to page 16

BYPASS CONVEYORS BPBE SINGLE-BELT WITH GLIDING PLATE - DIMENSIONS L max. 282 256 205 60 Link to CAD Data Type horizontal drive min. 385 mm / max. 10 m – belts over 10 m long on request

Open the catalog to page 17

PRODUCT DESCRIPTION BELT COUPLING BKE The belt coupling BKE is used for coupling a double- At the same time, the belt coupling BKE is also used belt conveyor TBD to a single-belt conveyor TBE, for for special applications, e.g. in conveyors in hot zones example for use as a positioning unit PVE (see if it is not possible to use a drive at the given tempera- page 46). Force transmission from conveyor to con- veyor is by means of a synchronous belt drive. Consequently, no second conveyor drive is required.

Open the catalog to page 18All MONTECH catalogs and technical brochures

-

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

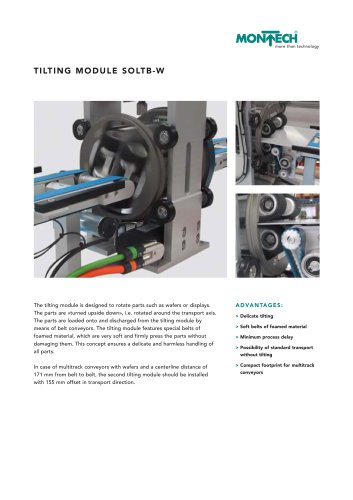

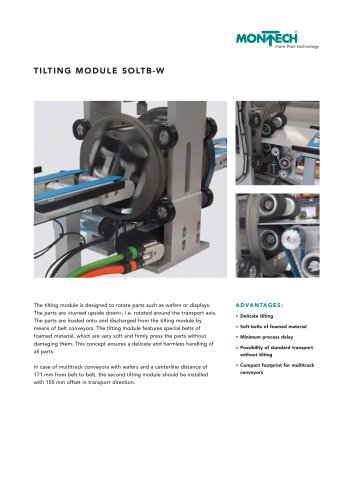

TILTING MODULE SOLTB-W�

2 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

Automation – Accessories

6 Pages