Catalog excerpts

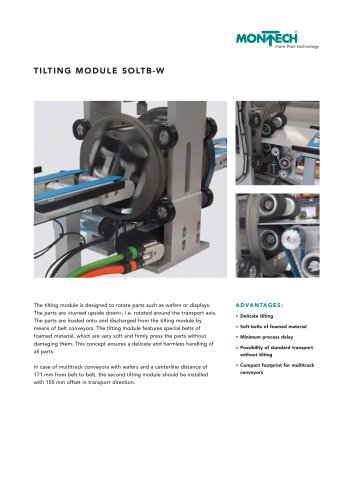

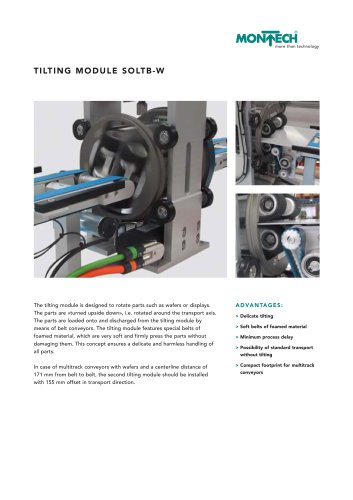

more than technology The tilting module is designed to rotate parts such as wafers or displays. The parts are «turned upside down», i.e. rotated around the transport axis. The parts are loaded onto and discharged from the tilting module by means of belt conveyors. The tilting module features special belts of foamed material, which are very soft and firmly press the parts without damaging them. This concept ensures a delicate and harmless handling of all parts. In case of multitrack conveyors with wafers and a centerline distance of 171 mm from belt to belt, the second tilting module should be installed with 155 mm offset in transport direction. > Compact footprint for multitrack conveyors > Delicate tilting > Soft belts of foamed material > Minimum process delay > Possibility of standard transport without tilting

Open the catalog to page 1

at transportet partsØ188 with 8 mm thickness counterbore for cheese head screws M6 attachment points Max. weight. 600 g, terminal area = max. 130 mm air unoiled, filtered to 5 µm, dew point < 6°C Driving medium Pneumatic connection Belt drive motor capacity Supply voltage/current Tilting drive motor capacity Intermediate circuit voltage/current Nominal voltage regulator Cycle time with wafer 156 x 156 mm min. 1.5 (loading – tilting – extracting) Cycle time (continuous) Ambient conditions: temperatur normal workshop atmosphere

Open the catalog to page 2All MONTECH catalogs and technical brochures

-

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

TILTING MODULE SOLTB-W�

2 Pages

-

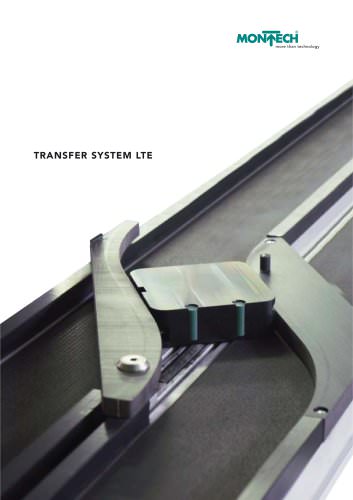

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

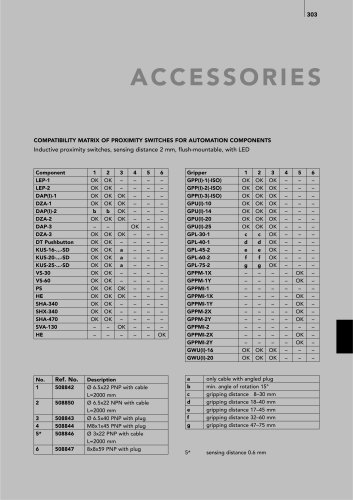

Automation – Accessories

6 Pages