Catalog excerpts

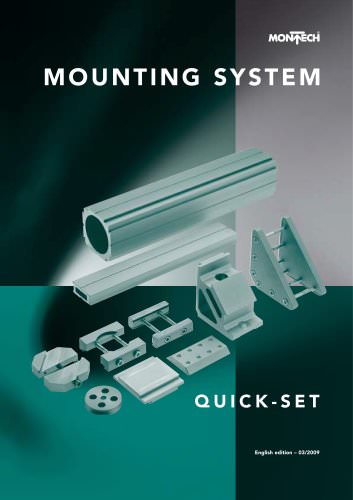

1 English edition – 03/2009 MOUNTING SYSTEM Q U I C K - S E T

Open the catalog to page 1

2 QUICK-SET MOUNTING SYSTEM Montech AG has stood for innovation in the automation industry since 1963. As a global player with headquarters in Switzerland, we base our success on maintaining flexibility and closeness to customers around the world. Quick-Set is a patented mounting system with cross-product compatibility and flexibility. Its proven dovetail fastening system permits rapid, uncomplicated assembly of all Montech products. The safety devices and cells are based on our Quick-Set mounting system. They are installed and expanded easily and quickly, even on existing machines.

Open the catalog to page 2

3 PROFILES 8 LOAD DIAGRAM 17 CLAMPING ELEMENTS 18 CONNECTORS 34 Modifications may be made without

Open the catalog to page 3

5 Precision, heavy-duty, vibration-proof two-part connections with dovetail geometry and clamping elements. For static as well as dynamic use. * With the screws tightened to 6 Nm torque, the strength of resistance to displacement between two interconnected profiles is 3000 N. A TECHNOLOGY WITH MANY POSSIBILITIES Form fit Form fit Frictional fit*

Open the catalog to page 5

6 QUICK-SET SIZE 40 PRODUCT DESCRIPTION 6kN Quick-Set is a universal modular system for mounting elements. The system makes it possible for fast installation without machining the profile ends. A variety of mounting options can be obtained with a minimum of individual elements (10 base elements). Quick-Set can be adjusted easily, quickly and precisely, without the need for drilling or pinning. Quick-Set is suitable for precise dimensionally-stable connections. Its dovetail connections can be subjected to larger loads than T-slot connections. With the screws tightened to the correct torque,...

Open the catalog to page 6

7 Quick-Set-connections are vibration proof and highly suitable for demanding applications. The connections established are precise, regardless of the treatment of the profile ends. Quick-Set makes it possible to set up linear connections as well as connections with adjustable angles. Its excellent flexibility makes it easy to reinforce mounting elements (vertical supports, horizontal carriers/diagonal braces). All the clamping screws of the mounting elements are always accessible. It is simple to disassemble and reuse the mounting elements at any time; clamping connections leave no...

Open the catalog to page 7

8 y y x x 26 40 8 16 Precision-extruded aluminum profile to DIN 17615, warm hardened, surface anodized natural, smooth ends. Profile area 368 mm2 Section modulus Wx = 1.025 cm3 Wy = 1.640 cm3 Moment of inertia Jx = 0.820 cm4 Jy = 3.280 cm4 Tolerance length DIN 7168 Distortion tolerance 1 mm/m Straightness tolerance 0.7 mm/m Weight 0.980 kg/m Ref. No. natural 1000 mm 44207N1000 2000 mm 44207N2000 SUPPORTING PROFILE TP-16-40

Open the catalog to page 8

9 Precision-extruded aluminum profile to DIN 17615, warm hardened, surface natural, smooth ends. Suitable for substructures and mounting elements which are not exposed to dynamic loads. Profile area 809 mm2 Section modulus Wx = Wy = 13 cm3 Moment of inertia Jx = Jy = 45 cm4 Tolerance length DIN 7168 Distortion tolerance 1 mm/m Straightness tolerance 0.7 mm/m Weight 2.186 kg/m Ref. No. natural 2000 mm 49260N2000 3000 mm 49260N3000 66 66 40 58 x x y y LIGHT PROFILE LP-66-40

Open the catalog to page 9

10 Precision-extruded aluminum profile to DIN 17615, warm hardened, surface anodized natural, smooth ends. Profile area 1480 mm2 Section modulus Wx = Wy = 23 cm3 Moment of inertia Jx = Jy = 76 cm4 Tolerance length DIN 7168 Distortion tolerance 1 mm/m Straightness tolerance 0.7 mm/m Weight 3.996 kg/m Ref. No. natural 2000 mm 42852N2000 3000 mm 42852N3000 Pack of 4x2 m 42852N4x2m Pack of 4x3 m 42852N4x3m x x y y 66 58 66 40 Ø 55 SUPPORTING PROFILE TP-66-40

Open the catalog to page 10

11 y y x x 40 96 96 96 Ø85 Precision-extruded aluminum profile to DIN 17615, warm hardened, surface anodized natural, smooth ends. Profile area 1767 mm2 Section modulus Wx = Wy = 37.82 cm3 Moment of inertia Jx = Jy = 181.53 cm4 Tolerance length DIN 7168 Distortion tolerance 1 mm/m Straightness tolerance 0.7 mm/m Weight 4.771 kg/m Ref. No. natural 3000 mm 43207N3000 SUPPORTING PROFILE TP-96-40

Open the catalog to page 11

12 Precision-extruded aluminum profile to DIN 17615, warm hardened, anodized natural, smooth ends. Used for making adapters. Profile area 271 mm2 Section modulus Wx = 0.32 cm3 Wy = 1.36 cm3 Moment of inertia Jx = 0.14 cm4 Jy = 2.72 cm4 Tolerance length DIN 7168 Distortion tolerance 1 mm/m Straightness tolerance 0.7 mm/m Weight 0.732 kg/m Ref. No. natural 1000 mm 41258N1000 2000 mm 41258N2000 x x y y 40 8 45° ADAPTER PROFILE AP-40-40

Open the catalog to page 12

13 y y x x 40 56 12 4 45° Precision-extruded aluminum profile to DIN 17615, warm hardened, anodized natural, smooth ends. Used for making adapters. Profile area 600 mm2 Section modulus Wx = 1.04 cm3 Wy = 4.83 cm3 Moment of inertia Jx = 0.67 cm4 Jy = 13.53 cm4 Tolerance length DIN 7168 Distortion tolerance 1 mm/m Straightness tolerance 0.7 mm/m Weight 1.620 kg/m Ref. No. natural 1000 mm 46253N1000 2000 mm 46253N2000 ADAPTER PROFILE AP-56-40

Open the catalog to page 13

14 x x y y 35 24 15.5 8.6 40 7 10.5 16 5 15 15 M5/M6/M8 5 15 15 M6 Precision-extruded aluminum profile to DIN 17615, warm hardened, anodized natural. With T-slot for M5, M6 and M8 square nut (non slip with drop protection) of steel, chemically nickel-plated. Section modulus Wx = 1.346 cm3 Wy = 1.7466 cm3 Tolerance length DIN 7168 Weight 0.8546 kg/m Ref. No. natural 2000 mm 45088N2000 Square nut M5 45089 M6 21913 M8 45091 non slip M6 45090/F non slip DIN PROFILE RAIL DP-40

Open the catalog to page 14

15 55 40 39.5 22 4 1.2 18.5 Snap-on profile for routing pneumatic hoses and electric cables – aluminum, warm hardened, anodized natural, smooth ends. Tolerance length DIN 7168 Weight 0.549 kg/m Ref. No. natural 1000 mm 45229N1000 2000 mm 45229N2000 CABLE DUCT, MULTIPLE KFM-40

Open the catalog to page 15

16 96 66 16 To cover the ends of the TP supporting profiles – material plastic (ABS), turquoise green or light-grey. Ref. No. light-gray turquoise AK-16-40 for TP-16-40 48619 44871 AK-66-40 for TP-66-40 or LP-66-40 48617 44869 AK-96-40 for TP-96-40 48618 44870 CAPS AK-16-40/AK-66-40/AK-96-40

Open the catalog to page 16All MONTECH catalogs and technical brochures

-

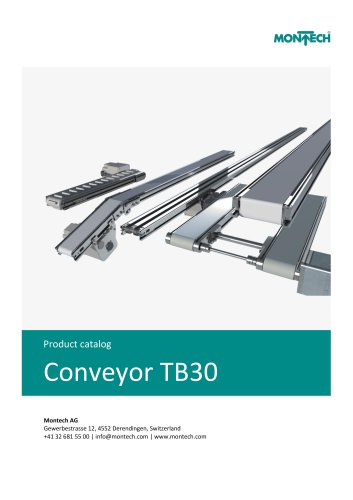

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

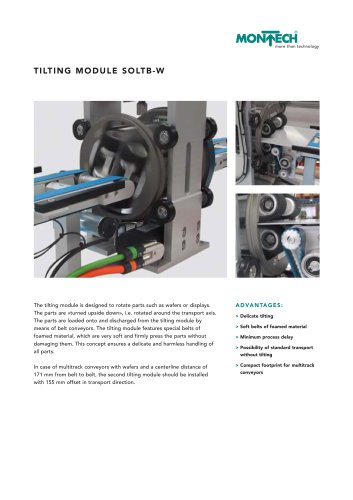

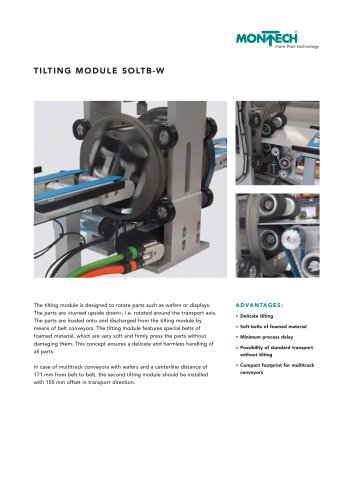

TILTING MODULE SOLTB-W�

2 Pages

-

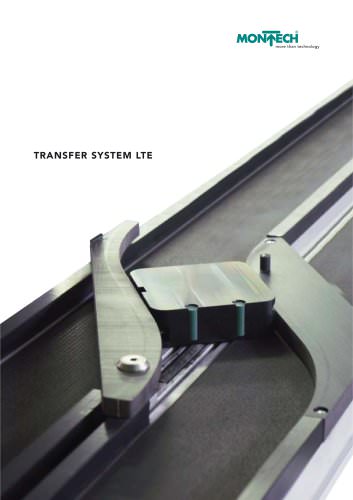

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

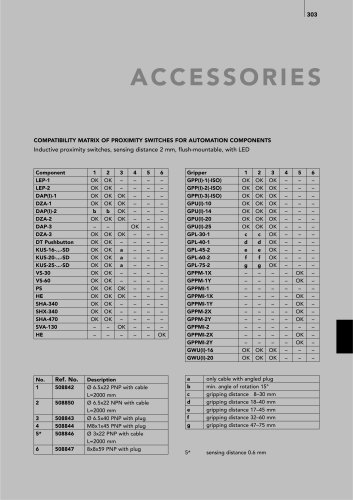

Automation – Accessories

6 Pages