Catalog excerpts

09/2010 English edition MONTRAC

Open the catalog to page 1

4 MONTRAC MONTRAC IN USE BY ... «With Montech’s technology, we could customize the transport system according to our production needs, eliminating dust, reducing consumption and optimizing the entire production cycle.» Vincenzo Lioy, Managing Director, Triom «Based on a positive result gained in a project, we know we can find a suitable solution to satisfy the requirements in terms of compact dimensions, small footprint, compatibility with aseptic environments, reliability and high availability.» Thomas Otto, CEO of Vetter Pharma-Fertigung GmbH & Co. KG «We are very satisfied with the...

Open the catalog to page 4

Montrac is an intelligent conveyor system for industrial production and logistical processes. Montrac exemplifies total flexibility when it comes to conveyor technology, providing virtually limitless possibilities combined with user-friendly simplicity throughout the entire system. Montrac has been optimizing production processes and intralogistics in innovative companies worldwide for over a decade. The Montrac intra-logistic solution guarantees that products are arriving at the proper destination at the right time. More importantly, it takes the most efficient path. When one wants to...

Open the catalog to page 6

MONTRAC-CONFIGURATOR 12 CONTROL SYSTEM 14 CHAOS TECHNOLOGY 16 Modification reserved TRACLINK 20 INTELLIGENT MODULES 82 TRACCROSSING 36 TRACSWITCH ARENA 32 LIFT 39 TOUCHPANEL 84 FRAMEWORKS 70 TRACDOOR 68 TRAC 18 TRACCURVE 22 TRACSWITCH 28 SHUTTLE 51 PALLET 55 SUPOTRAC/ERGOTRAC 57 POSITIONING UNIT 60 CONTENTS SOLUTION PATHS 8 MONTRAC 7 POWER SUPPLY 88 LOGIBOX 86 SPECIAL COMPONENTS 91 ACCESSORIES 97

Open the catalog to page 7

8 MONTRAC Are you planning a new production system or expanding an existing production facility? The Montrac monorail system provides you with fast and flexible solutions. Montrac is an intelligent transport system networking industrial production and logistic processes. Envision your production and logistics in the future – Montrac can help you realize that vision today. Montrac will revolutionize your logistic and production workflow. SOLUTIONS FOR YOUR PRODUCTION SYSTEM APPLICATION EXAMPLES Intra-logistics and assembly line In one of the largest engine plants in the world, production and...

Open the catalog to page 8

MONTRAC 9 SIMPLICITY FLEXIBILITY CLEANROOM RELIABILITY Montrac was designed to be extraordinarily simple. It is comprised of very few components, making design and assembly very easy compared to ordinary conveyor systems. The Trac components are quick to assemble. Other than a straight cut, there are no machining processes required. The exclusive use of electronic components eliminates the need for pneumatic connections and complicated wiring. Chaos Technology greatly reduces cabling and programming. You will benefit from this simplicity not only during assembly but also when changing or...

Open the catalog to page 9

10 MONTRAC PROFITABILITY & COST EFFICIENCY Montrac’s latest developments are aimed at increasing the system’s efficiency. Montrac is driven solely by electricity – there are no costly pneumatic components or connectors. Power is supplied directly through the conductor rails; this means there is very little to no cabling required. With Chaos Technology, programming and controls hardware is reduced or eliminated. Cost comparison over 6 years: Conventional conveyor system with 34 motors, 11 stations, and 48 pallets. Montrac with 24 Shuttles and 11 process stations. 1. Implementation costs 2....

Open the catalog to page 10

MONTRAC 11 MONTRAC – FOR A CLEANER ENVIRONMENT Montrac is not only attractively priced, it is also environmentally friendly. A conveyor belt system with 34 motors consumes $20,000 worth of electricity a year, whereas a comparable Montrac system only consumes $600. This equates to a significant reduction in environmental impact. Conveyor belt Montrac An analogy using automobiles illustrates this point from a different perspective: a Montrac Shuttle would be able to travel more than once around the world (estimated distance of 26,600 km) using only two tanks of fuel.

Open the catalog to page 11

12 MONTRAC Using our free configuration tool, you can configure Montrac systems yourself and experiment with different layouts. This tool lets you easily adapt the path of the monorail to your facility to create the perfect solution for your specific needs and spatial restrictions. Your floor plan can be imported in 2D or 3D (DWG or DXF). The intuitive construction handles make it easy to design systems. The required control elements (IRMs & proximity switches) can be added with the click of a mouse. You can toggle between 2D and 3D views for a choice of layout views. There is also an...

Open the catalog to page 12

MONTRAC 13 3D CONFIGURATION CONSTRUCTION HANDLES AUTOMATIC PLACEMENT OF CONTROL ELEMENTS LIBRARY WITH PRECONFIGURED SECTIONS The screen is divided into a vertical menu bar, a large configuration window, and a function and selection view. The configuration window is where you configure the Montrac system in real time. The resulting system is shown as a realistic 3D rendering, or as a bill of materials. Simple spatial elements can be used to simulate an existing building element for planning purposes. Zones can be created where layouts can then be placed and referenced. The user’s manual is...

Open the catalog to page 13

14 MONTRAC The IRM & ISM (Intelligent Routing Modules & Intelligent Shuttle Modules) are used to control the Trac and Shuttles in a Montrac system. The IRM and ISM are infrared communication modules that exchange data allowing Shuttle, Trac, and work station to interact. The ISM Shuttle module, and IRM Trac module, communicate with each other. In addition to communicating with the ISM, the IRM can also control TracSwitchs and Crossings when programmed to operate autonomously. TRAVEL CONTROL WITH IRM & ISM

Open the catalog to page 14

MONTRAC 15 CONNECTION BOXES AND CABLES MONTECH IRM & ISM CONFIGURATION SOFTWARE INTERFACES CONTROLLING THE TRAVEL SPEED An IRM is needed at each stopping point in the system. At the minimum, it serves to detect and start the Shuttles. The «IRM Basic» assembly serves this purpose. It consists of an IRM, a connection cable, an AB-cam (speed reduction), and an A-cam (stop). Various connection kits are available for specific uses: connection box (terminal box) for a single IRM, with or without proximity switch holder; connection box for two IRMs and a proximity switch holder; and connection box...

Open the catalog to page 15All MONTECH catalogs and technical brochures

-

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

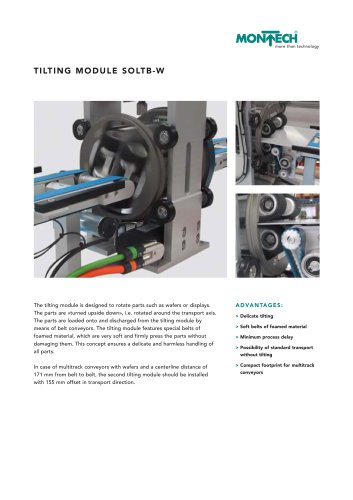

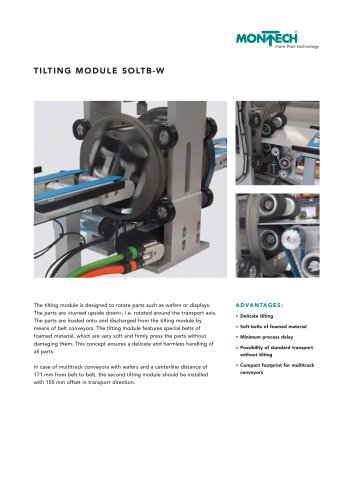

TILTING MODULE SOLTB-W�

2 Pages

-

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

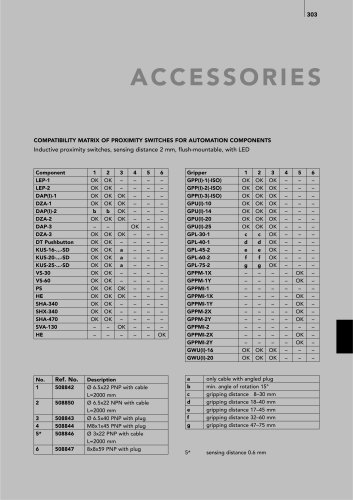

Automation – Accessories

6 Pages