Catalog excerpts

DESIGNED TO BE MAINTENANCE FREE > 2120 size="-1">

Open the catalog to page 11

RELIABILITY One of the most compelling advantages of theMontrac system is that none of the wear items are single points of failure.Ӕ A shuttle can be removed at anytime so that Montrac runs at anytime with no single point of failure. The Trac itself is a passive element and not subject to failure. The shuttle was designed to be maintenance free. > SIMPLICITY Montrac was designed to be extraordinarily simple. It iscomprised of very few components, making design and assemblyeasy. The Trac components are quick to assemble. Other than a straight cut, there are no machining processes required....

Open the catalog to page 18

PROFITABILITY/EFFICIENCY Montrac offers multiple opportunitiesto quickly get a return on your investment. It reduces cycle time and improves the utilization of production capacities. Montrac has a smaller footprint, optimizing real estate. Powering parts while in transit may allow you to capitalize on idle time. Montrac consumes 95% less electricity and no compressed air when compared with tradi- tional systems. The simplicity of Montrac means considerably less time spent designing, installing, and programming. Montrac likewise provides benefits that are less quantifiable. For example,...

Open the catalog to page 19

NO MAINTENANCE Montrac is the only transport system requiringabsolutely no maintenance! Mechanical components constitute atiny portion of the overall system and were developed with longevity in mind. The Trac itself is a passive element and is not subject to wear.The shuttle is self-propelled by a brushless DC motor. All bearings aresealed and lubricated for life. The components are preset and meet the most exacting quality standards. Modular design means that the unlikely minor repair can be made easily. Since all components complywith EMC and ESD requirements, they are not a potential...

Open the catalog to page 20

Ryan Johnson, Engineer, Hewlett-Packard CLEANROOM Montrac is perfectly suited for cleanrooms. Theshuttles are self-propelled and therefore have no dirty belts. There isno sliding friction to create particulate. Even its form reduces air turbulence. The standard components were designed for a class 1000cleanroom. With minor adjustments we have reached class 100according to US Federal standard 209E. > Roman Wieser, Siemens VDO Firstline Manager TRAVEL TIME BECOMES PRODUCTION TIME Montrac hasdeveloped an additional current collector on the shuttle that can continuously supply 3 A at 24 VDC to...

Open the catalog to page 21

ANTISTATIC AND ELECTROMAGNETIC PROPERTIES TheMontrac-System exceeds the highest antistatic requirements andmeets European electromagnetic interference guidelines, EMC,EN 50081-2 and EN 50082-3. These features open a wide range of possible applications in electronics and computer industries. PRODUCT SIZE UP TO 500 x750mm HANDLING FROM BELOW With Montrac it is possible to work onthe product from below by ejecting the pallet from the shuttle and moving it to the side. This can be done while the shuttle is moving so production is not interrupted. Pulling the pallet aside allows fullaccess to...

Open the catalog to page 22

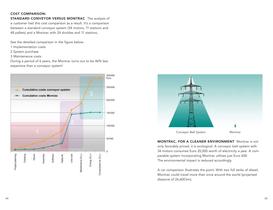

COST COMPARISON: STANDARD CONVEYOR VERSUS MONTRAC The analysis of a customer had this cost comparison as a result. Its a comparison between a standard conveyor system (34 motors, 11 stations and 48pallets) and a Montrac with 24 shuttles and 11 stations.See the detailed comparison in the figure below:1 Implementation costs2 System purchase 3 Maintenance costs During a period of 6 years, the Montrac turns out to be 46% lessexpensive than a conveyor system! > Conveyor Belt SystemMontrac MONTRAC, FOR A CLEANER ENVIRONMENT Montrac is notonly favorably priced, it is ecological. A conveyor belt...

Open the catalog to page 23

TRACCURVE Montrac trans-port system includes 90 and 45а curves. With a connectingradius of only 280 mm, Montrac offers unparalleled flexibility. INTERACTIVE MONTRAC-CONFIGURATOR Using ourfree configuration tool, you can configure Montrac systems yourself and experiment with different layouts. This tool lets you easily adapt the path of the monorail to your facility to create the perfect solution for your specific needs and spatial restrictions. Your floor plan can be imported in 2D or 3D (DWG or DXF). TRACLINK The TracLink is theconnection between two Trac sections. It allows the Trac tobe...

Open the catalog to page 25

TRACSWITCH ARENA The TracSwitch Arena either diverts Shuttles into a bypass (45) or allows them to con- tinue on the main Trac. The TracSwitch Arena makes it possible to perform a com- plete bypass with a single component. The TracSwitch Arena is electrically operated and is powered directly from the conductor rails. LIFT The lift transportsShuttles vertically for the following tasks: Ж Bridging over forklift paths Connection of two or moresystems with different work- ing heights֖ Transport of Shuttles from astation to a ceiling systemand vice versa. TRACSWITCH The switchserves to divide...

Open the catalog to page 26

Maximum speed: 30 m/minCurrent consumption: ~ 0.8 A Amps at max. constant speed per driven axle Standard dimensions and mass:200x300 mm EPV Mass (pallet length 300,400, 550 mm): 11.6, 12.8, 14.6 kg MPV Mass (pallet length 300, 400, 550 mm): 12.6,14.7,16.8 kg Repeatability of pallet positioning EPV: In X and Y 0.02 mm, in Z ѱ0.2 mm Repeatability of pallet positioning MPV: In X and Y 0.03 mm, in Z ѱ0.2 mm Maximum additional force: 3 kN, with reinforcement from below 25 kN Time to change a pallet: 2.85 s > 2 Single-axle Shuttle ; 2.5 kg200x400 mm > 2 Maximum payload: 12 kg ; 3.3 kg300x400 mm >...

Open the catalog to page 27

QUICK-SET QUICK-SET > This is a profilesystem that is compatible with all products. It is specifically designed for dynamic loads, but it is equally suitable as static framework. It is based on our proven dovetail system. Quick-Set TRAVEL CONTROL WITHIRM SCALE MODULE The scalemodule is a SupoTrac with a built-in high-precision scale from the Eilersen company. As the Shuttle drives in the SupoTrac, the pallets are lifted and weighed with accuracy to within 1/10 gram Ζ no impact or vibration. This module is used in intralogistic applications as well as to verify processes in assembly systems....

Open the catalog to page 28All MONTECH catalogs and technical brochures

-

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

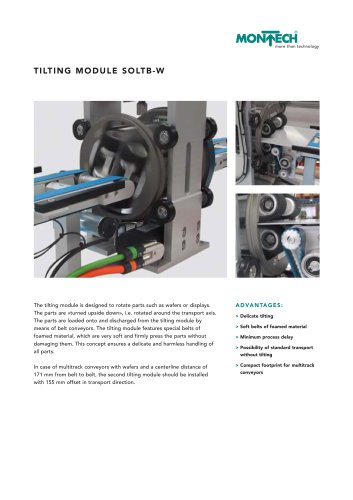

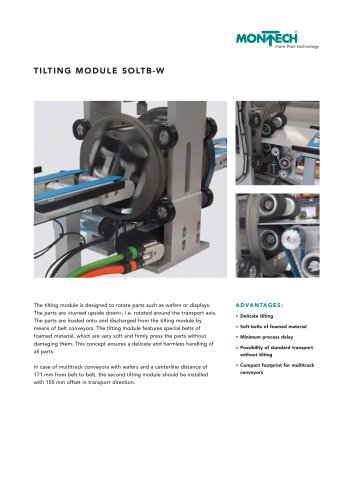

TILTING MODULE SOLTB-W�

2 Pages

-

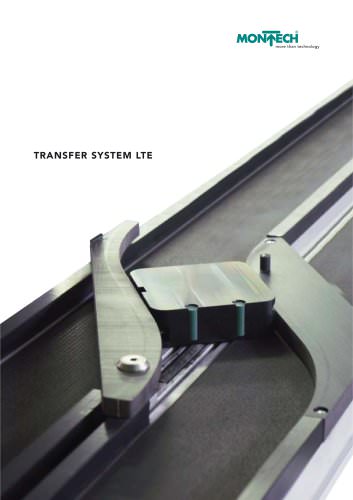

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

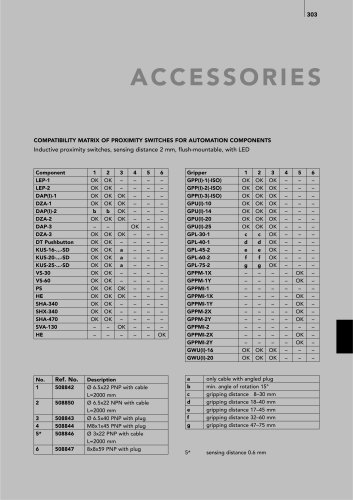

Automation – Accessories

6 Pages