Catalog excerpts

more than technology

Open the catalog to page 1

CUSTOMIZED SOLUTIONS Watch industry Electronics industry Construction industry Mechanical engineering Plastics industry Printing industry Automotive suppliers Medical industry Automotive suppliers Solar industry Medical industry Automotive suppliers Mechanical engineering Airport industry Airport industry Electronics industry

Open the catalog to page 2

PRODUCT DESCRIPTION TECHNICAL DATA Max conveyors GTB are used to carry parts to or from the various manufacturing stations, or combined to form complete transport systems. The modular construction of the system permits simple adaptation to specific customer requirements. The conveyor is driven by a 230/400 V spur gear motor. This permits transportation of up to 125 kg in conveying mode. The following chassis widths are available: 200, 300, 400, 500, 600, 700 and 800 mm (widths up to 1200 mm on request). The max conveyor is available with end drive. The warranty is 24 months from date of...

Open the catalog to page 3

MAX CONVEYORS GTB - PRODUCT DESCRIPTION The belt speed can be altered by simply exchanging sprockets and chain or with the aid of a frequency converter, if variable speed is requested. Conveyor products are complemented by our full range of accessories and special fittings (dependent on the chassis width selected). This includes various belt types for different applications, stands and lateral guides. Accessories can be included in the future easily, quickly and without mechanical processing.

Open the catalog to page 4

MAX CONVEYORS GTB - TECHNICAL DATA Ambient temperature normal workshop atmosphere Noise level Gear motor 3 400V/50 Hz frequency converter 1 x 230 V/50 Hz Category of protection Type of switching Insulation of motor windings Thermal protection delta/star for frequency converter operation with phase isolation 2 thermal sensors (from 130 °C) Start/stop operation On-time Material aluminum, anodized natural Deflecting rollers Drive roller steel rubber-coated aluminum PU, steel Gear motor Sliding plate nickel-plated/option stainless steel Connecting support aluminum, anodized natural, plastic

Open the catalog to page 5

MAX CONVEYOR WITH END DRIVE GTB-K - PRODUCT DESCRIPTION The Max conveyor with end drive GTB-K is driven by a 230/400 V spur gear motor. This permits transportation of up to 125 kg in conveying mode. The following chassis widths are available: 200, 300, 400, 500, 600, 700 and 800 mm (widths up to 1200 mm on request). The GTB-K model is a variant at affordable costs thanks to its simple construction. The end drive version can be fitted above or below the belt depending on available space. The top drive version can transport products up to 80 mm high. The possible belt length is between 1 and...

Open the catalog to page 7

MAX CONVEYOR WITH END DRIVE GTB-K - DIMENSIONS L left right Type A [mm] L Gear motor Ref. No. E [mm] min. 1m / max. 6 m – belts shorter than 1m and longer than 6 m on request 3G90F71/4D63b4-8 G90F/4D63b4-8

Open the catalog to page 8

Operat. temp., continous Required force for 1% rotation Maximum permissible force meets European food regulations meets US food regulations Important! Cleats not possible in combination with nose bar! Color of conveying side inclined Surface of conveying side Method of transport: horizontal Manufacturer’s designation dark green Food Chemistry Pharmaceuticals Mounting systems, general Electronics industry (electrically conductive) Effect of oil and grease For high operating temperatures Printing industry High-performance belt, high mechanical and chemical resistance Standard belts

Open the catalog to page 9

MAX CONVEYOR WITH END DRIVE GTB-K - CLEATS1) PQS-8 NAB-8EEDV 11 Manufacturer’s designation Suitable for belt type Manufacturer’s designation Suitable for belt type Field of application Color Cleat height h Suitable for belt type Manufacturer’s designation Cleat spacing 4) Cleat spacing A = 2 length L [mm] + 60 number of cleats 4) Number of cleats = 2 length L [mm] + 60 cleat spacing A Cleated belts require at least two weeks delivery time For legend, see page 9 The tolerance of the cleat spacing A is ± 2 mm Length L see page 8

Open the catalog to page 10

MAX CONVEYORS WITH END DRIVE GTB-K - LOADING LIMITS Belt speed Belt width End- drive in conveying mode Belt speed Belt width End drive in buffering mode

Open the catalog to page 11

Mode of drive BA = permissible starting load in %, BD = permissible continuous load in % For max conveyors with nose bar the maximum permissible speed is 39.6 m/min also in use with frequency converter.

Open the catalog to page 12

MAX CONVEYORS WITH END DRIVE GTB-K - TECHNICAL DATA DRIVE No. of drive roller teet Current consumption Spur gear Gear type/ Motor type Belt speed [m/min] All motors are fitted with heat sensors (130 °C).

Open the catalog to page 13

MAX CONVEYOR GTB - BELT FABRICATION Montech procures the belt for you according to the list of belt codes below. LIST OF BELT CODES Structure of our code: 10/0457/02326/1 Connection code (see code below) Belt length (always 5-digit) Belt length (always 4-digit) Belt number (see code below) No. Belt designation Connection code Connection Connection Connection Connection code code code code endless flexproof endless thermofix open beveled cut square Connection code 1 is prefarable! CALCULATION OF BELT LENGTH It can be downloaded from our homepage (www.montech.com). You can find the file...

Open the catalog to page 14

MAX CONVEYOR WITH END DRIVE GTB-K - CALCULATION FORMULAS Calculation of lateral guide length L Lc Calculation of sliding plate length LG GTB with 2 deflection rollers Ø 60 mm: LC = L – 154 mm TB with 1 deflection roller Ø 60 mm and 1 nose bar: LC = L – 194 mm GTB-K with 2 deflection rollers Ø 60 mm: LG = L – 140 mm GTB-K with 1 deflection roller Ø 60 mm and 1 nose bar: LG = L – 86 mm Calculation of belt length An Excel table is used for calculating the belt length. It can be downloaded from our homepage (www.montech.com). You can find the file Gurtlä nge GTB ... .xls under Support Service

Open the catalog to page 15

MAX CONVEYOR WITH END DRIVE GTB-K - SUPPORT SPACING CALCULATION L Length of profile lateral Spacing between supports Loading of belt per 1000 mm. The total loading over the entire length of the conveyor must not exceed 125 kg maximum in conveying mode, refer also to table of loading limits, page 13. Weight per meter Y Due to high surface loading, additional supports are necessary to increase the stability of the sliding plate. The optimum number of supports is calculated from the above diagram. Determination of dimension X 1. Determine belt load per meter (e.g. 50 kg). 2. Choose the curve...

Open the catalog to page 16All MONTECH catalogs and technical brochures

-

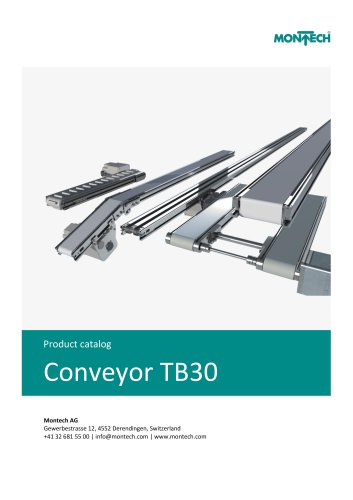

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

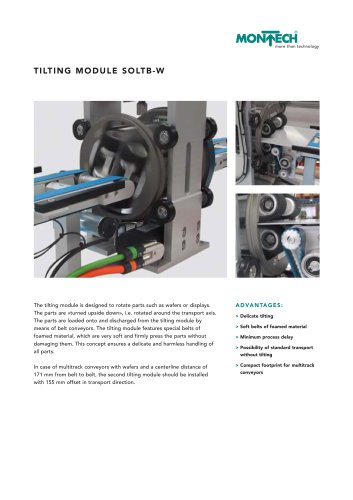

TILTING MODULE SOLTB-W�

2 Pages

-

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

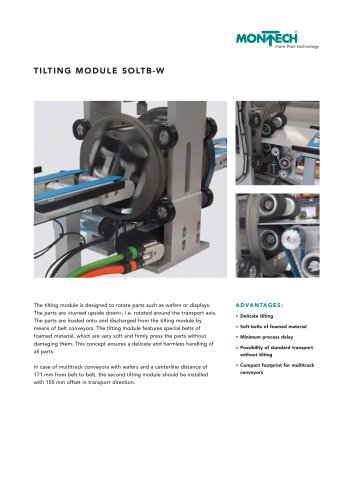

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

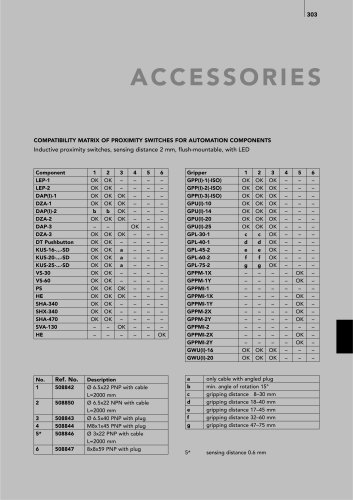

Automation – Accessories

6 Pages