Catalog excerpts

2 Montech AG has stood for innovation in the automation industry since1963. As a global player with headquarters in Switzerland, we base our success on maintaining flexibility and closeness to customers around the world. Montech offers ordinary and configurable conveyors in three differentversions and an asynchronous conveyor system. The products are based on our many years of experience and are knownfor their high quality in almost every industry. >

Open the catalog to page 2

3 CONTENTS PRODUCT DESCRIPTION4 TECHNICAL DATA6 WORKPIECE HOLDER WT8 CONVEYOR TB/TBD10 BYPASS CONVEYORS BPBE13 BELT COUPLING BKE15 BELT FABRICATION17 CONVEYORS COMPONENTS19 FIXED CURVE 90 KFE26 MOVABLE CURVE 90а KBEA/KBE28 ROTARY DIVERTERS UR-18031 BYPASS BPEA/BPE37 TRANSFER GATE WEE40 INDEXING DEVICE IVE42 INDEXING DEVICE IVEB44 POSITIONING UNIT PVE46 ACCESSORIES49 > Modifications may be made withoutnotice. size="-2">

Open the catalog to page 3

The single-belt transfer system from Montech is an asynchronous transfersystem whose function is to automatically guide workpieces through thenecessary workstations according to their asssembly sequence.The workpieces to be processed are attached to standardized workpieceholders made of high-strength plastic and are carried on single-belt con-veyors.The modular system makes it possible to implement the automationprocess step-by-step. Subsequent modifications can be made with mini-mum expenditure. >

Open the catalog to page 4

5 Bypass BPEAFixed curve 90 KFE Positioning unit PVE Belt coupling BKE Typical application criteriaare: Е assembly automation and logistics overall weight per workpiece holder up to 2.5 kgՕ system arrangement inline˻ and/or offline˻ repeatabilityձ 0.05 mm four workpiece holders: 80 x 80, 115 x 115, 160 x 160 and 225 x 225 mm To ensure a high degree of flexibility, we recommend the use of the profilesystem Quick-Set as a substructure. It is based on a dovetail clampingprinciple, requires no drilling or pinning, and can be used universally. >

Open the catalog to page 5

Ambient temperature +10 to +40 CRel. humidity< 95% (without condensation) Air puritynormal workshop atmosphereNoise level[dBA]< 70 Degree of protection of componentsIP 54 R > WTE in IVE/IVEB/PVE[mm]б 0.05 Workpiece holder WTE sizes80x80 mm (weight: 170 g)115x115 mm (weight: 360 g) 160x160 mm (weight: 690 g)225x225 mm (weight: 1660 g)Max. weight WTE 80, 115, 160 (with load)[kg]2.5 Max. weight WTE 225 (with load)[kg]5 Max. torque on WTE in IVE/IVEB[Nm]5 Max. pressure on WTE in IVE/IVEB[N]120 Max. pressure on WTE in PVE*[N/mm > 2 ]15Operating pressure[bar]56 Operating medium air, oiled or...

Open the catalog to page 6

The workpiece holder WTE made from high-strength plastic is available infour standard sizes: 80 x 80, 115 x 115, 160 x 160 and 225 x 225 mm. Depending on the design of the pallet transfer system and the preferreddirection of transport, version A or mirrored version B is used. The permis-sible total weight of each workpiece holder, including workpiece receiverand product, is 2.5 kg. >

Open the catalog to page 8

G 8 1 7 ABC 20 H 10D4 10 E F Version AVersion B All drawings are available at www.montech.com for download. WTE 80x80 WTE 115x115WTE 160x160WTE225 x 225 for TB-105for TB-140for TB-185for TB-250 A80115.0160225.0 B40057.5080112.5 C17025.0045025.0 D80115.0160225.0 E19019.0019019.0 F24024.0024024.0 G30057.0072077.0H55090.0135200.0 Ref. No. WTE 80x80WTE 115x115WTE 160x160WTE 225 x 225Version A 49609496104961156307 Version B 49639496384963656306 >

Open the catalog to page 9

The conveyor both modular and proven in design forms the basis of thetransfer system. Chassis widths of 105, 140, 185 and 250 mm are used for the respective workpiece holders. The conveyors are driven by a 3 x 230/400 V central spur gear drive. Belt speeds can be varied simply and economically between 7.5 and19.9m/min using conversion kits.The construction is precise, stable and durable. All steel parts are nickelplated or made from non-corroding materials; deflecting rollers are stain-less, and the drive rollers are coated with vulcanized rubber. >

Open the catalog to page 10

A 10.5 C B 0.25 X 0.25 > M50 L4=99֘G80F=122.2 6 1.5 14 G80F = ؘ 122.2 40 9 16(4) 12 2.5 5.5 11 > 11.5 328 A Direction of travel All drawings are available at www.montech.com for download. leftrightH = horizontal drive V= vertical drive 42.5 V 70 35 > 11.5 H 175 V 144 H 245 > TypeTB-105TB-140TB-185TB-250 A [mm]105140185250 B 0.5 mm 081116161226 C084119164229 X075090135200LHorizontal drive min. 425 mm, vertical drive min. 324 mmmax. 10 m і Belts over 10 m long on request size="-1">

Open the catalog to page 11

40 9 16 12 (4) 2.5 5.5 11 25 16 D 16 25 > 11.5 328 A Direction of travel All drawings are available at www.montech.com for download. leftrightH = horizontal drive V= vertical drive 11.5 42.5 175 245 > TypeTBD-105TBD-140TBD-185TBD-250 A [mm]105140185250 B 0.5 mm 081116161226 C084119164229 D023058103168LHorizontal drive min. 425 mm, vertical drive min. 324 mmmax. 10 m і Belts over 10 m long on request size="-1">

Open the catalog to page 12

The bypass belt permits the installation of two parallel conveying sectionswith only one drive unit. The distance between the two conveyor belts is12mm. Consequently, the inward and outward transfer elements (seecatalog, pages 37 to 39) can be installed in the bypass belt for construction of a bypass. >

Open the catalog to page 13

TB conveyor end with deflection roller, single-beltRef. No. TB-105 56990 TB-140 56991 TB-185 56992 TB-250 56993 TBD conveyor end with deflection rollers, dual-beltRef. No. TBD-105 56994 TBD-140 56995 TBD-185 56996 TBD-250 56997 >

Open the catalog to page 19

TB drive unit horizontal, single-beltRef. No. TB-105 54332 TB-140 57996 TB-185 57997 TB-250 57998 TB drive unit vertical, single-beltRef. No. TB-105 54333 TB-140 58001 TB-185 58002 TB-250 58003 Motor support for vertical driveRef. No. TB-105 to TB-250 56531 >

Open the catalog to page 20

BPBE conveyor end with deflection roller Ref. No. TB-105 56990 TB-140 56991 TB-185 56992 TB-250 56993 Chassis binder BPBE Ref. No. BPBE 55145 BPBE drive unit horizontal Ref. No. TB-105 56907 TB-140 56908 TB-185 56909 TB-250 56910 >

Open the catalog to page 22

23 BKE conveyor end with deflection >

Open the catalog to page 23

The kit for fixed curve 90ڰ KFE can simply screwed onto the conveyorprofile.A finger protection device between the conveyors is also installed manually;it ensures optimum operational safety. In only a few minutes, the 90connection can be installed. The fixed curve allows queing while within the curve. This keeps the controlsystem simple and saves costs as there is no need for stoppers in front ofthe curves. As an alternative to two fixed curves, with 180а deflections, the rotarydiverter UR-180 can be used. >

Open the catalog to page 26All MONTECH catalogs and technical brochures

-

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

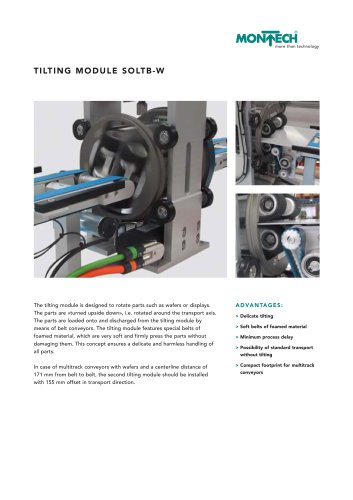

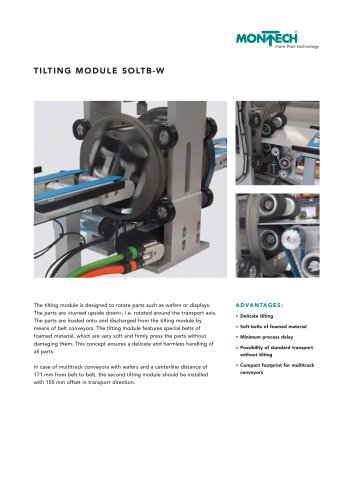

TILTING MODULE SOLTB-W�

2 Pages

-

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

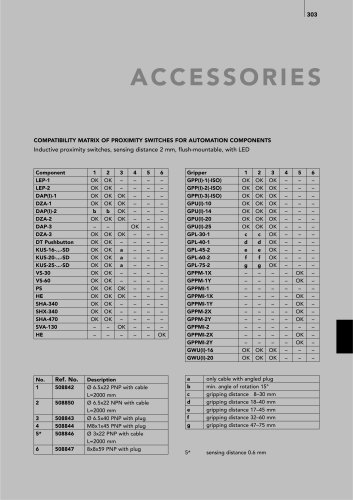

Automation – Accessories

6 Pages