Catalog excerpts

Montech AG has stood for innovation in the automation industry since 1963. As a global player with headquarters in Switzerland, we base our success on maintaining flexibility and closeness to customers around the world. Montech offers ordinary and configurable conveyors in four different versions and an asynchronous conveyor system. The products are based on our many years of experience and are known for their high quality in almost every industry.

Open the catalog to page 2

3 CONTENTS Modifications may be made without notice. 08/2010 KTB CALCULATION FORMULAS 10 KTB TECHNICAL DATA 9 KTB-K SINGLE-BELT 14 KTB PRODUCT DESCRIPTION 7 KTB-M SINGLE-BELT 18 KTB-K DUAL-BELT 22 KTB-M DUAL-BELT 26 KTB ACCESSORIES 30 INTRODUCTION 4 GTB CALCULATION FORMULAS 122 GTB TECHNICAL DATA 121 GTB-K END DRIVE 134 GTB PRODUCT DESCRIPTION 119 GTB-M CENTER DRIVE 138 GTB-T DRUM DRIVE 143 GTB ACCESSORIES 146 TB CALCULATION FORMULAS 78 TB TECHNICAL DATA 77 TB SINGLE-BELT HORIZ. 84 TB PRODUCT DESCRIPTION 75 TB SINGLE-BELT VERT. 88 TBD DUAL-BELT HORIZ. 92 TBD DUAL-BELT VERT. 96 TTBD HORIZ....

Open the catalog to page 3

4 OUR CONVEYOR CONFIGURATOR UNDER WWW.MONTECH.COM By visiting www.montech.com, you can access our Conveyor configurator, in two versions On the basis of your specific requirements and desires the Product Based Configurator proposes a conveyor according to the «Best Price principle». All necessary data for the solution of your requirements of transportation are queried in linear order. False configurations are excluded in advanced by conducting a plausibility check by the program. If you already know which type of conveyor you need; you will choose the Conveyor Based Configurator option....

Open the catalog to page 4

5 COMPONENT KITS A novel concept from Montech: conveyors as component kits. All parts of the component kit are available from stock (except for belts and sliding plates – these are provided also by the customer). This concept offers you more flexibility in the construction of conveyors, in the adaptation of our conveyors as customer-specific solutions and in assembly – of course we also still supply completely assembled conveyors.

Open the catalog to page 5

6 For the high-quality component kits, we provide simple assembly instructions and our complete CE-compliant operating instructions. You can download all 2D and 3D construction data of the conveyors free of charge from our website. We will support you with thorough training of your assembly personnel for assembly of the conveyors. We look forward to cooperating with you. Call us. Phone +41 32 681 55 00, www.montech.com, info@montech.com or Phone USA +1 704 655 6400 OUR SERVICE PACKAGE Simple mounting instructions Training of your personnel Internet support

Open the catalog to page 6

7 Minidrive conveyors KTB are used to carry parts to or from the various manufacturing stations, or combined to form complete production lines. Thanks to the compact design and integrated control, the minidrive conveyor is the ideal solution for many applications. – the minidrive conveyors conform to CE recommendations – we provide a 2 year warranty from date of delivery – available with end and center drive The belt is driven by a regulated, brushless 24 V DC motor with variable speed and selectable direction. The switchable electric motor brake is durable and considerably reduces run-out...

Open the catalog to page 7

8 The drive position in the end drive is continuously pivotable through 270°. At the top position, parts can be conveyed to a height of 40 mm. The maximum length is 5 m. The durable and user-friendly keypad is the interface between user and minidrive conveyor. The three-digit illuminated display shows the ACTUAL speed of the minidrive conveyor. The intelligent control electronics regulate the belt speed independently of load. The belt speed can be varied in the standard version. The following types are available: Version L v = 0.4–7.6 m/min in steps of 0.1 m/min Version S v = 1.2–21.0 m/min...

Open the catalog to page 8

9 MINIDRIVE CONVEYORS KTB TECHNICAL DATA Ambient temperature +10 to +40 °C Rel. Humidity < 95% (without condensation) Air purity normal workshop atmosphere Noise level < 55 dBA Protection category of the drive unit IP 40 Version L S Belt speed 0.4 – 7.6 m/min 1.2 – 21.0 m/min Increments 0.1 m/min 0.2 m/min Motor Type brushless external-rotor DC motor Rated voltage 24 V DC Operating voltage 18 to 28 V DC Rated current 2.8 A Max. current consumption 3.6 A (at start) Gear Type two-stage spur gear Maintenance none needed Connection Connecting cable 4-pin, coupling angled at 90° Cable...

Open the catalog to page 9

10 MINIDRIVE CONVEYORS KTB CALCULATION FORMULAS FOR CHASSIS, GLIDING PLATE, AND BELT LENGTHS L Lc L Lc End drive Center drive End drive Center drive Calculation of chassis length Chassis length Lc = L – 149 mm Lc = L – 120 mm Calculation of gliding plate length Gliding plate length LG = L – 150 mm LG = L – 121 mm Calculation of belt length KTB with 2 deflection rollers Ø 30 or Ø 40 mm G = (2 x L + 44 mm) x 0.995 G = 2 x L + 167 mm KTB with 1 deflection roller Ø 30 mm and 1 nose bar not possible G = 2 x L + 185 mm KTB with 2 nose bars not possible on request KTB with additional tensioning...

Open the catalog to page 10

11 Structure of our code: 11/0075/02432/1 KTB end drive Conveyor definition: KTB-105KLS, L= 1200 mm, belt type FAB-2E according to formula on page 10: G = (2 x L + 44 mm) x 0.995 = 2431.78 mm (round up or down) Belt definition 11/0075/02432/1 KTB center drive Conveyor definition: KTB-80L, L= 2380 mm, with 1 x deflecting roller Ø 30 mm and 1 x nose bar, belt type ENI-5EE according to formula on page 10: G = (2 x L + 185 mm) = 4945 mm Belt definition 15/0050/04945/1 LIST OF BELT CODES CALCULATION EXAMPLES Connection code (see code below) Belt length (always 5-digit) Belt width (always...

Open the catalog to page 11

12 HRVT-101 Manufacturer’s designation FNB-5E FAB-2E FNI-5E ENI-5EE TF-NRN HNB-5E HAT-5E Thickness [mm] 1.3 0.7 0.9 1.2 0.35 1.3 1.5 Dimensions [kg/m2] 1.5 0.7 0.9 1.2 0.5 1.5 1.8 Min. drum Ø [mm] R41) R41) R41) R41) 30 R41) 25 k1% [N/mm] 5 2 5 5 5 5 5 kperm. [N/mm] 8 3 8 8 5 8 8 ìG (Conveying mode)2) 0.25 0.25 0.25 0.25 0.2 0.25 0.25 ìG (Buffering mode)2) 0.5 0.5 0.5 0.5 0.4 0.5 – Operating temp., cont. [°C] –15/80 –30/80 –30/80 –30/80 –200/260 –15/80 0/80 Operating temp., briefly [°C] –20/110 –30/110 –30/110 –30/100 –200/260 –20/110 –10/110 Field of use L, Ch, L, Ch, L, Ch, Mo, El, HT,...

Open the catalog to page 12All MONTECH catalogs and technical brochures

-

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

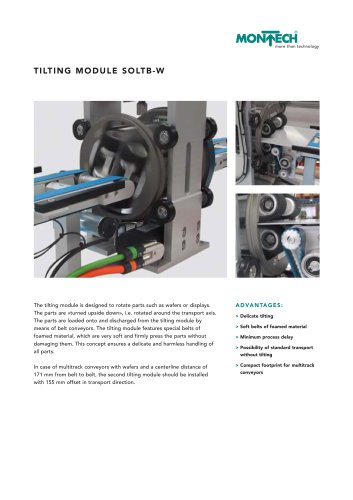

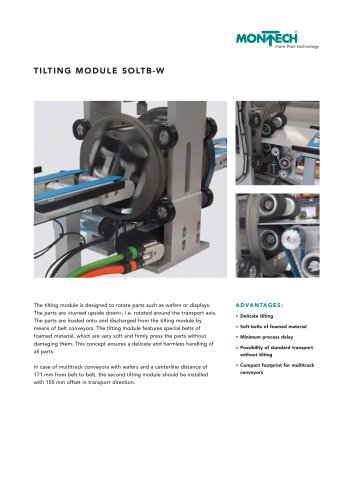

TILTING MODULE SOLTB-W�

2 Pages

-

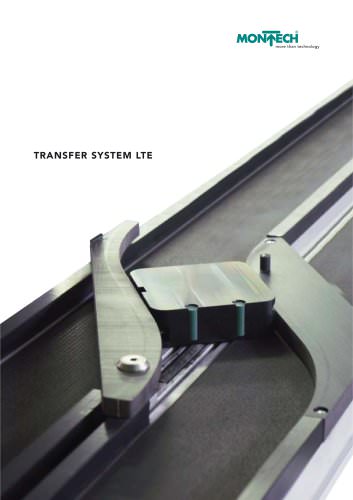

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

Automation – Accessories

6 Pages