Website:

MONTECH

Website:

MONTECH

Catalog excerpts

Product catalog Conveyor TB30 Montech AG Gewerbestrasse 12, 4552 Derendingen, Schweiz +41 32 681 55 00 | info@montech.com | www.montech.com

Open the catalog to page 1

CUSTOMIZED SOLUTIONS Watch industry Electronics industry Construction industry Mechanical engineering Plastic industry Printing industry Automotive suppliers Medical industry Automotive suppliers Solar industry Medical industry Automotive supplier Mechanical engineering Airport industry Airport industry Electronics industry

Open the catalog to page 2

Modifications may be made without notice. PRODUCT DESCRIPTION TECHNICAL DATA DRIVE OPTIONS END DRIVE DIMENSION DRAWINGS CONVEYOR TB30 WITH BRUSHLESS DC-MOTOR DIMENSION DRAWINGS CONVEYOR TB30 WITH THREE-PHASE MOTOR CONVEYOR BELTS CLEATED BELTS LOAD LIMITS ANGULAR JOINT BELT SUPPORT TB30 COMPONENTS ACCESSORIES

Open the catalog to page 3

The conveyors are either as single belt or as dual belt versions available. For transporting larger pallets and other dimensionally stable products, it is possible to use the tandem conveyor: here, two conveyors are connected by means of a vibration-reducing, clearance-free elastomer coupling and driven by only one motor (other versions on request). The drive unit can easily and freely be positioned on the chassis, whereby a position close to the belt exit is recommended. The tensioning systems enable a precise adjustment of the initial belt tension and belt tracking. A number of different...

Open the catalog to page 4

Center drive Center drive End drive (Motor available on right or left side) End drive (Motor available on right or left side) Three-phase motor (fixed conveying speed) Brushless DC-Motor (variable conveying speed) Center drive End drive, right version End drive, left version * also available with cleated belts

Open the catalog to page 5

PRODUCT DESCRIPTION CONVEYOR TB30 SINGLE BELT Different standard lengths are available, while the length can be defined in one-millimeter steps according to specific customer requirements. The drive system transmits the power at low loss and without slipping to the belt. For heavy loads, especially in buffering mode, all belts can be provided with a gliding plate integrated in the chassis (from chassis width 60 on upwards). For the drive you have the choice between a brushless DC motor for variable speeds and a three-phase motor for fixed speeds.

Open the catalog to page 6

PRODUCT DESCRIPTION CONVEYOR TB30 DUAL BELT The conveyor TB30 dual-belt is suitable for standard applications as well as specific uses, including: – operations from the bottom side (for instance, visual inspection or manipulation) – conveying sensitive products (the support measures 2x16 mm only). With a powerful drive, strong belts and modular components, this type of conveyor is ideal for many applications. Different standard widths are available, while the length can be defined in one-millimeter steps according to specific customer requirements. The distance between the belts can also be...

Open the catalog to page 7

PRODUCT DESCRIPTION CONVEYOR TB30 TANDEM The conveyor TB30 tandem is particularly suitable to carry large pallets and other cumbersome items with stable shape. The solution consists of two belts connected by means of an elastomer coupling, thus driven costefficiently by one single motor. The gap between the two belts can be defined as required, up to 1,000 mm. With modular components, this type of conveyor is ideal for many applications. Different standard widths are available, while the length can be defined in one-millimeter steps according to specific customer requirements. The drive...

Open the catalog to page 8

TECHNICAL DATA CONVEYOR TB30 Ambient temperature Rel. humidity Air purity Noise level Drive Brushless DC-Motor Connection Voltage/frequency Nominal rating Rated current Category of protection Gear reduction ratio Conveying speed +10 to +40 °C < 85% (without condensation) normal workshop atmosphere < 60 dBA by external controller 1x200-240V, 50Hz / 1x100-120V, 60Hz 120 W 0.78 A motor IP65 / controller IP20 10, 15, 30 variable (refer to p. 10) 8 cycles per minute Start-Stop Three-phase motor Voltage/frequency Nominal rating Rated current Category of protection Gear reduction ratio Conveying...

Open the catalog to page 9

Conveying speed brushless DC-motor [m/min] [m/min] [m/min] [m/min] [m/min] [m/min] Conveying speed Three-phase motor i=10.18 Ref.No. 66692 66349 Typ Center drive (3x400 V / 50 Hz) Center drive (3x460 V / 60 Hz)

Open the catalog to page 10

Weight brushless DC-Motor with gliding plate Weight Base length L = 1000 mm Single belt Dual belt Weight three-phase motor with gliding plate Weight Base length L = 1000 mm Single belt Dual belt

Open the catalog to page 11

DRIVE OPTIONS Brushless DC-Motor with external controller 1 x 200-240 V, 50 Hz 1 x 100-120 V, 60 Hz Controller - variable speed when operating manually (stepless) - predefining of up to four different speeds when operating over I/O’s - simple switching of direction of rotation - configurable acceleration ramp - ON-OFF function Connecting cable motor <-> controller Available in lengths 1, 5 and 10 m Three-phase motor 3 x 400 V, 50 Hz 3 x 460 V, 60 Hz for constant conveying speeds In our standard product range, we have two different motors available for the drive. When variable speed is...

Open the catalog to page 12

END SECTION Different end sections are available for selection. Depending on the application, the diameter of the deflection rollers can vary – ø20, ø30 or ø40 mm. For a smooth and safe transport of small parts - especially when transferring from parts from one conveyor to the next - a end section with a knife edge with radius R4 mm can be selected. The dimensions of the end selections can be found on pages 14 – 21. End section End section with deflection roller Ø 30 mm, single belt Center drive End section with deflection roller Ø 30 mm, dual belt End section with deflection roller Ø 20...

Open the catalog to page 13

DIMENSION DRAWING CONVEYOR TB30/M BRUSHLESS DC-MOTOR 60 mm for end section with deflection roller or knife edge / 90 mm for end section with tension roller (more tension path) 90 mm for end section with deflection roller or knife edge / 120 mm for end section with tension roller (more tension path) Typ A chassis B conveying width ±0.5 i) C gliding plate D belt distance X belt width ii) F lateral guide width width for conveyors with lateral guide fixed. Information about conveying width with lateral guide adjustable on page 22. Only for single belt. Belt width for dual belt version is always...

Open the catalog to page 14All MONTECH catalogs and technical brochures

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

Conveyor TB30

57 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

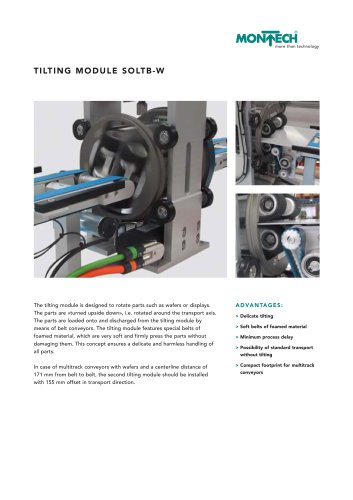

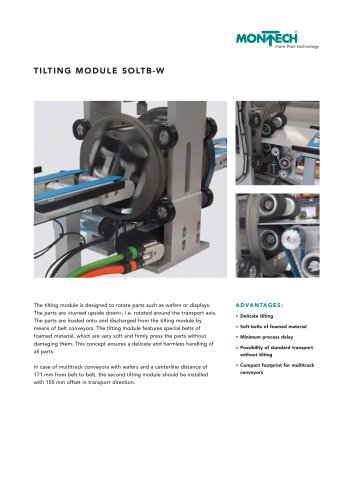

TILTING MODULE SOLTB-W�

2 Pages

-

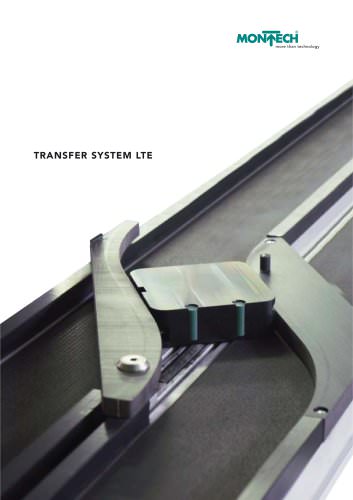

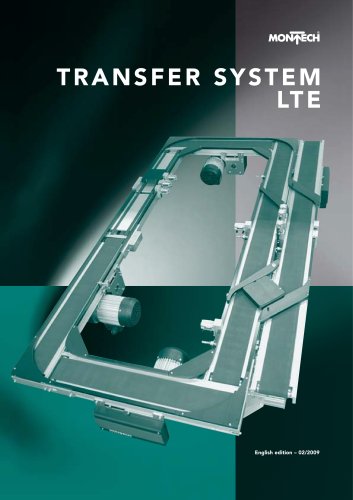

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

Automation – Accessories

6 Pages