Website:

MONTECH

Website:

MONTECH

Catalog excerpts

BASIC CONVEYORS BTB PRODUCT DESCRIPTION BTB PRODUCT DESCRIPTION BTB TECHNICAL DATA BTBD-M DUAL-BELT In spite of a compact drive unit, up to 40 kg can be transported. BTBD-K DUAL-BELT The following chassis widths are available: 45, 60, 80, 105, 140 185 and 250 mm. BTB-M SINGLE-BELT The belt is driven by an induction motor with spur gear unit maintenancefree. The conveyor can run at five different speeds and, optionally, it is available in single- and dual-belt versions. Thanks to the inverter the the speed can be set up countinuously variable BTB-K SINGLE-BELT – the basic conveyors conform to CE recommendations – we provide a 2 year warranty from date of delivery – available with end and center drive Basic Conveyors BTB are used to carry parts to or from the various manufacturing stations, or combined to form complete production lines. Thanks to the compact design, the basic conveyor is the ideal solution for many applications.

Open the catalog to page 1

BASIC CONVEYORS BTB PRODUCT DESCRIPTION BTB-K single-belt end drive BTB-M single-belt center drive BTBD-K dual-belt end drive BTBD-M dual-belt center drive Frequency converter The center drive is suitable for long conveyor belts up to 10 m. The deflection roller diameter is only 30 mm. The drive unit can be positioned anywhere along the free chassis length. The drive position in the end drive is continuously pivotable through 270°. At the top position, parts can be conveyed to a height of 70 mm. The maximum length is 5 m.

Open the catalog to page 2

BASIC CONVEYORS BTB TECHNICAL DATA Ambient temperature normal workshop atmosphere Noise level Protection category of the drive unit Motor Nominal power output Operating voltage Nominal current Gear spur gear Maintenance Material none needed aluminium, anodized natural Deflecting rollers stainless steel, plastic POM Drive roller Drive unit stainless/nickel-plated steel, aluminum, plastic ABS Protective plate Belt speeds aluminium, anodized natural Belt speeds with frequency converter with gliding plate Weight (base L = 1000 mm) Type Basic Conveyor Basic Conveyor with dual-belt

Open the catalog to page 3

BASIC CONVEYORS BTB CALCULATION FORMULAS FOR CHASSIS, GLIDING PLATE, AND BELT LENGTHS Center drive Calculation of chassis length Chassis length Calculation of gliding plate length Gliding plate length Calculation of belt length BTB with 2 deflection rollers

Open the catalog to page 4

BASIC CONVEYOR BTB BELT FABRICATION Version 1 You order the belt yourself from the manufacturer in the table below. You determine the belt length using the formula at the bottom of Version 2 Montech procures the belt for you according to the list of belt codes LIST OF BELT CODES Connection code (see code below) Belt length (always 5-digit) Belt width (always 4-digit) Belt number (see code below) Connection code 1 = endless flexproof Connection code 2 = endless thermofix Connection code 3 =open beveled Connection code 4 = cut square CALCULATION EXAMPLES BTB end drive Conveyor definition:...

Open the catalog to page 5

BASIC CONVEYOR BTB BELT TYPES HRVT-101 Manufacturer’s designation Thickness Operating temp., cont. Operating temp., briefly Method of transport Horizontal Buffering Rejection of goods Inclined Surface of conveying side Color of conveying side k1% Required force for 1% elongation kperm. Maximum permissible force µG Coefficient of friction – in buffering mode: belt to product (steel) – in conveying mode: belt to sliding substructure Food Chemistry Pharmaceuticals Mounting systems, general Electronics industry (electrically conductive) Effect of oil and grease For high operating temperatures...

Open the catalog to page 6

BASIC CONVEYORS BTB DETERMINATION OF THE LOAD LIMITS Load limits of the belt mG To ensure that the chosen Basic Conveyor optimally fulfills the specific conditions of use, all influencing factors must be taken into account. The maximum permissible loading of a Basic Conveyor is limited by two elements: Element 1: Permissible belt loading (mG perm. see below) Element 2: Load limit of the drive (mA perm. see page 48) 1. Determination of the permissible belt loading force (mG perm. using the two data: belt type and belt width X (in mm). Conveying mode FNB-5E Belt width Permissible belt load mG...

Open the catalog to page 7

BASIC CONVEYORS BTB DETERMINATION OF THE LOAD LIMITS Load limits of drive mA 2. Determination of the permissible load limits of the drive (mA perm. using the three data: Belt speed v [m/min], coefficient of friction µG1), drive mode. Evaluation: For the maximum permissible loading of the Basic Conveyor, the lower of the two values of mG and mA is always critical. Belt speed Load limit Permissible belt load mA perm. [kg] as a function of µG1) Drive mode Permissible starting load in % of mA perm. 3 x 230 V, with freq. converter Coefficient of friction µG, see page 46

Open the catalog to page 8

BASIC CONVEYOR DIMENSIONS FOR END DRIVE SINGLE-BELT All drawings are available at www.montech.com for download. Front drive Drive mode L: Total length incl. belt, tolerance ± 2 mm. Right drive (also available with left drive). Rear drive is an unfavorable drive mode – use only when really necessary. conv. width min. 300 mm / max. 5 m – belts over 5 m long on request

Open the catalog to page 9

BASIC CONVEYORS COMPONENTS FOR END DRIVE SINGLE-BELT BTB-K end with deflection roller, single-belt BTB-KR drive unit, single-belt BTB-KL drive unit, single-belt

Open the catalog to page 10

Chassis for gliding plate Gliding plate stainless * customer-specific in mm, several plates possible When ordering chassis for gliding plate and glide plate without assembly, the gliding plate is attached only per customer’s request.

Open the catalog to page 11

BASIC CONVEYORS COMPONENTS FOR END DRIVE SINGLE-BELT BTB gear motors Induction motor MY BASIC CONVEYOR WITH END DRIVE SINGLE-BELT BTB-K conveyor end drive unit chassis / chassis for gliding plate gliding plate

Open the catalog to page 12

BASIC CONVEYOR DIMENSIONS FOR CENTER DRIVE SINGLE-BELT All drawings are available at www.montech.com for download. conv. width min. 360 mm / max. 10 m – belts over 10 m long on request

Open the catalog to page 13

BASIC CONVEYORS COMPONENTS FOR CENTER DRIVE SINGLE-BELT BTB end with deflection roller, single-belt BTB drive unit, single-belt

Open the catalog to page 14All MONTECH catalogs and technical brochures

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

Conveyor TB30

57 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

CONVEYOR TB30

57 Pages

-

RB40 Roller Conveyor

18 Pages

-

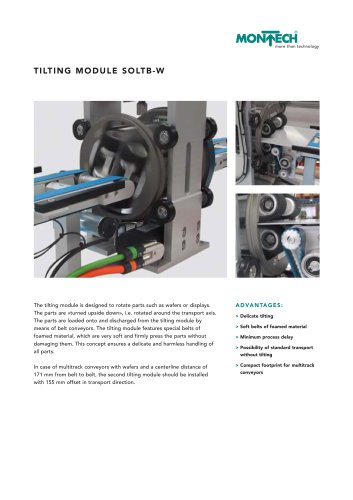

TILTING MODULE SOLTB-W�

2 Pages

-

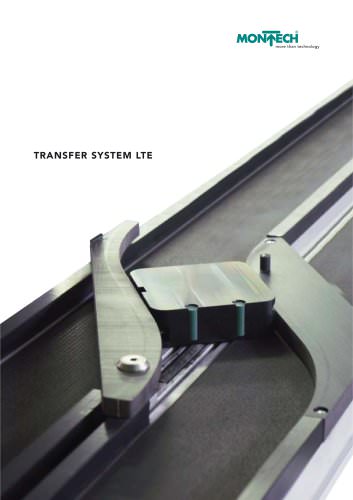

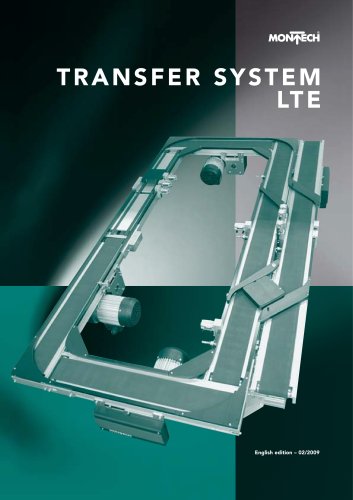

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

Automation – Accessories

6 Pages