Catalog excerpts

LINEAR UNITS LEP CONTENTS PRODUCTDESCRIPTION1215 APPLICATIONS 16֖17 LINEAR UNITS18 >

Open the catalog to page 3

12 > LINEAR UNITS LEP PRODUCT DESCRIPTION The Linear UnitsLEP are designed for horizontal and verticalmounting.The drive is provided by a standard ISO-CETOP pneumatic cylin-der, which can be exchanged with ease from the rear housing.Together, the hardened precision round bars recessed in the enclosed section of the slide and the running rollers of the case body form the backlash-free, adjustable guide system. >

Open the catalog to page 5

13 in front behind The stroke is limited by stops, which contain a fine adjustment and hydraulic shock absorbers. The switching status is indicated by integral LEDs that are visiblefrom the outside through holes in the case.The end positions are scanned by stationary, inductive proximityswitches (included). >

Open the catalog to page 6

14 The cable and hose routing is enclosed using a standard protectivehose (size 1) or a power supply chain (size 2).All cables are combined on a terminal strip in the horizontal LinearUnit. All Linear Units use Quick-Set > dovetails > ή to allow fast mounting andsimple adjustments (see Quick-Set chapter from page 338). Thedovetails are arranged on both sides of the case to allow the LEP to be used for transfer (confined fitting conditions). >

Open the catalog to page 7

15 version A version Breturn spring The encapsulated form of construction eliminates danger pointsand ensures a quite process.The Linear Units are available in two versions. Version A includes aretracted and adjustable extended position. With version B an additional (second) adjustable extended position can be obtained.For weight compensation, LEPs intended for vertical mounting areprovided with a return spring. In the event of an emergency stopor drop in compressed air pressure, the vertical slide is drawn auto- matically to the upper end position. >

Open the catalog to page 8

16 > APPLICATIONS Pick-and-Place application; mounted on Quick-Set > under-frame with horizontal and vertical Linear Unit LEP, Rotary Drive DAPl with internal air feed and Double-Acting Grip- per GPDl. Press charging; attachment provided with vertically applied Stroke Unit HE, horizontal Linear Unit LEP and with Quick-Set > ή , as well asAngleGripper GW-180. >

Open the catalog to page 9

17 Workpiece loading and unloading; provided with Universal Slide US and Linear Units LEP for vertical and horizontal motion and attached revolver head. (Assembled with Quick-Set > ,Rotary Drive DAP and Preci- sion Parallel Gripper GPP). Revolving head; provided with Quick-Set > ή elements, a vertical Linear Unit LEP, a Rotary Drive DAP and two Precision Parallel Grippers GPP. >

Open the catalog to page 10

18 > LINEAR UNITS LEP HORIZONTAL/VERTICAL SCOPE OF DELIVERY Linear Unit, including two shock-absorbers, two exhaust-air throttles, two proximity switches for A-versionand five proximity switches for B-version, protective hose PG 29 or power supply chain and operating instructions. > SUITABLE ACCESSORIES Special accessoriesfrom page 38 Accessoriesfrom page 302 Quick-Set > from page 338 >

Open the catalog to page 11

19 Horizontal units > POINTS OF ACTION OF FORCES AND TORQUES (F > z .L > y ) > adm. = (F > y .L > z ) > adm. Vertical units (F > x . L > y ) adm. = (F > y . L > x ) > adm. The effective static sum of the forces occurring (+F > z or F > z ) can bedetermined with due allowance for the attached mass, the operat- ing pressure, the set stroke and the setting of the return spring from the force diagrams. >

Open the catalog to page 12

21 Linear Units LEP-60-1A/B vertical Stroke40 mmOperating pressure5 bar Attached weight(e.g. gripper + fingers + product): 2.5 kg StipulationThe attached weight (2.5 kg) will be moved to the vp˻ position with pres-sure loss (0 bar). 1)Inward force when retracted (stroke = 0, pressure = 0 bar) =25 N25 N ** = 0 N(line a))2)Lines a) ֖ b) c) lead to a spring setting S > F of 26 mm3)Stroke 40 mm; line d)4)Inward force when retracted (stroke = 0, pressure = 5 bar) =101 N֖25 N ** = 76 N(line e))5)Inward force when extended (stroke = 40 mm, pressure = 5 bar) =114 N25 N ** = 89 N(line f) und...

Open the catalog to page 14

38 > SPECIAL ACCESSORIES HOSE HOLDER Used when pneumatic hoses and/or electric cable must be takenfrom any unit to a point provided for hose connection PG-29. Mounted with an SP-32E-40 on the dovetail system.Typ SH-29 42334 Example: Direct attachment of a slide to a horizontal Linear Unit. > European projection POWER SUPPLY CHAIN ATTACHMENT SET This is necessary when a power supply chain is to be used insteadof the standard protective hose. The scope of delivery includes the connection set for the power supply chain, all Quick-Set > fixingangles and sections necessary and a cover cap for...

Open the catalog to page 31

39 > SERVICE ACCESSORIES RUSH-TYPE HAND GUN for easy relubrication of LEPs, SHAs and SVAs via lubricating nipples. 504720 > OIL CONTAINER (filled), 100 ml filled with oil Klber Paraliq P460, suitable for all Montech automation components 504721 >

Open the catalog to page 32All MONTECH catalogs and technical brochures

-

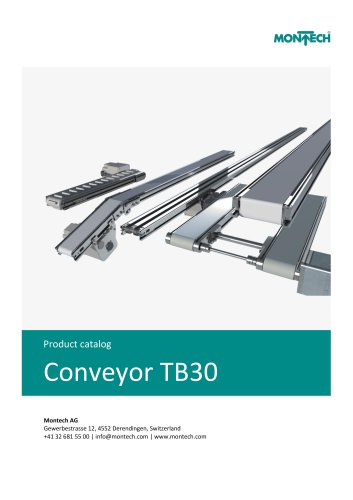

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

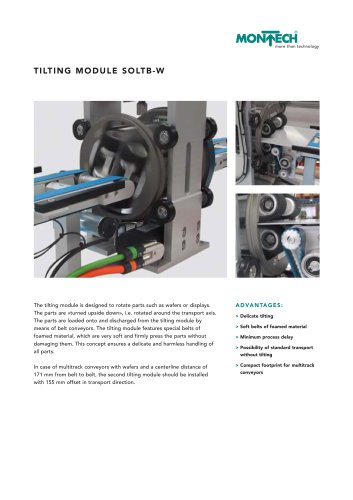

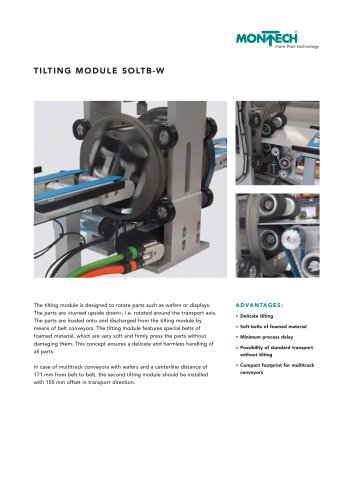

TILTING MODULE SOLTB-W�

2 Pages

-

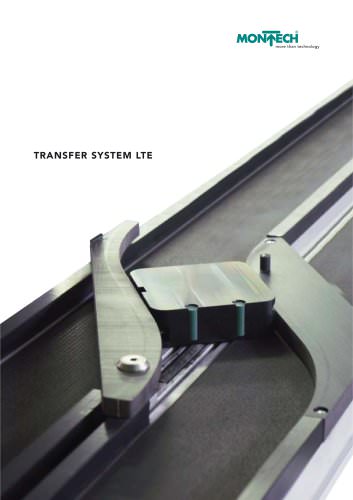

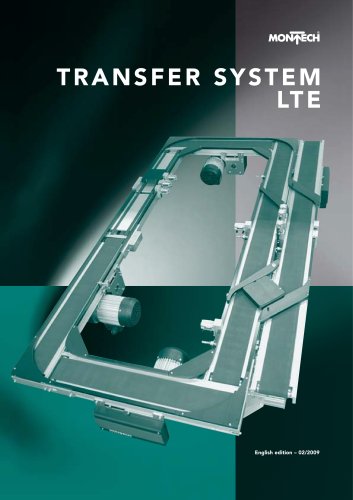

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Grippers

63 Pages

-

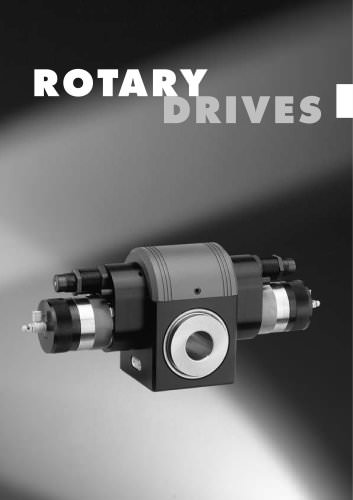

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

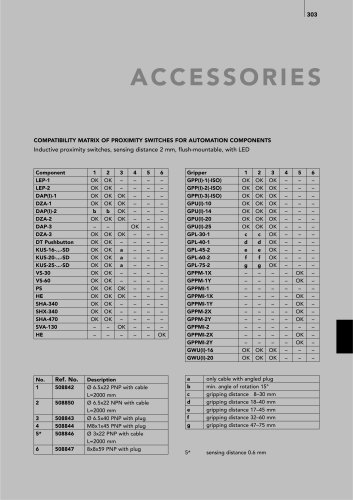

Automation – Accessories

6 Pages