Catalog excerpts

With its electrical handling components, Montech is now offering some-thing new: an electrical alternative to its tried-and-tested pneumatic units. The variety of functions open up a broad range of applications.The KUSE slides are used for linear movements, the DAE-60 rotary drivesfor rotational movements, and for gripping we recommend the GPE parallel gripper and the GWE angular gripper.All components have built-in brushless, electronically commutated DCmotors that require no maintenance.Thanks to the position control, the KUSEs and DAEs offer optimal repeatprecision. An optional holding...

Open the catalog to page 2

PARALLEL GRIPPERGPE PRODUCT DESCRIPTION4 TECHNICAL DATA6 TRAVEL TIMES6 DIMENSIONED DRAWING7 LOAD CALCULATIONS8 SCOPE OF DELIVERY9 CONTENTS ANGULAR GRIPPERGWE PRODUCT DESCRIPTION10 TECHNICAL DATA12 TRAVEL TIMES12 DIMENSIONED DRAWING13 LOAD CALCULATIONS14 SCOPE OF DELIVERY16 ACCESSORIES GPE AND GWE17 ROTARY UNITDAE-60 PRODUCT DESCRIPTION18 TECHNICAL DATA20 TRAVEL TIMES21 DIMENSIONED DRAWINGS22 LOAD CALCULATIONS24 SCOPE OF DELIVERY26 ACCESSORIES27 COMPACT UNIVERSAL SLIDEKUSE PRODUCT DESCRIPTION28 KUSE-830 KUSE-1033 LOAD CALCULATIONS36 SCOPE OF DELIVERY39 ACCESSORIES40 EC MOTOR CONTROLLERECMR...

Open the catalog to page 3

The electric parallel gripper GPE is designed for interior and exteriorclamping. The home position can be set so that the gripper is open orclosed.The GPE is driven by a brushless, electronically commutated DC motor. It is driven by a toothed belt on a ball screw. This enables fast, low-noise opening and closing (a plastic cushion provides end position shock absorp- tion). To protect the gripper against soiling, the mechanism is closed.The GPE has a rugged, low-friction clamping jaw guide which absorbs themain forces of cylinder rolls. The grippers are extremely compact and havetwo bore...

Open the catalog to page 4

Compact The specific arrangement of the drive elements has made it possible toachieve a narrow GPE design. This enables it to be manipulated in smallplaces. Practical The closed mechanism permits deployment of the GPE almost anywhere. Precise Direct transmission produces low backlash operation that results in repeatprecision of 0.05 mm. Installation position The installation position is freely selectable. Fast setup The device can be mounted with our Quick-Set elements. This makesmounting and adjustment fast, easy and flexible. Threaded and positioning bores are available as an alternative....

Open the catalog to page 5

Order no.: 57833Scope of delivery: 1 Electric parallel gripper GPE with EC motor, and 3m motor-data cable.The cable is towable, wired on one side and fastened to the GPE with ascrewed cable gland.1 EMCR controller, parameterized and fitted with terminals. 1 CD-ROM with commissioning software for Windows and OperatingInstructions in German, English, French and Italian. >

Open the catalog to page 9

The electric angular gripper GWE is designed for exterior clamping. The GWE is driven by a brushless, electronically commutated DC motor. It isdriven by a toothed belt on a ball screw. This enables fast, low-noise open-ing and closing (a plastic cushion provides end position shock absorption).The special shape of the jaw drive crank generates very high gripping forcesfor a parallel gripping finger position without a self-locking effect. Theopening angle is adjustable.The grippers are extremely compact and have two bore holes for inductiveproximity switches for end position detection. The...

Open the catalog to page 10

Compact The specific arrangement of the drive elements has made it possible toachieve a narrow GWE design. This permits it to be manipulated in smallplaces. Practical The jaw opening position can be infinitely adjusted from 15 to 180 and is cushioned by an elastic stop. In many cases handling movements are madeunnecessary thanks to the maximum opening angle. Precise Direct transmission produces low backlash operation that results in repeat precision of б0.05 mm. Installation position The installation position is freely selectable. Fast setup The device can be mounted with our Quick-Set...

Open the catalog to page 11

MoyMoy MozMoz Mox Lz FsFs LxLxLxLxFozFozFoyFoy Ly F > S :[N]Clamping force per gripper fingerF > oy , F > oz :[N]Static forces L > x , L > y , L > z :[mm]Distances over which force actsM > ox , M > oy , M > oz :[Nmm]Static moments F > S [N]see clamping force diagram F > oyadm. [N]80 F > ozadm. [N]400 L > xadm. [mm]60 L > yadm. [mm]60 L > zadm. [mm]120 M > ox adm. = (F > oy .L > z ) + (F > oz .L > y )[Nmm]2000 M > oy adm. = F > oz .L > x [Nmm]6000M > oz adm. = (F > S .L > y ) + (F > oy .L > x )[Nmm]3000 When M > ox , M > oy , and M > oz act simultaneously, each moment can reach its...

Open the catalog to page 15

Order no.: 57834Scope of delivery: 1 Electric angular gripper GWE with EC motor, and 3m motor-data cable. The cable is towable, wired on one side and fastened to the GWE with ascrewed cable gland.1 EMCR controller, parameterized and fitted with terminals. 1 CD-ROM with commissioning software for Windows and OperatingInstructions in German, English, French and Italian. >

Open the catalog to page 16

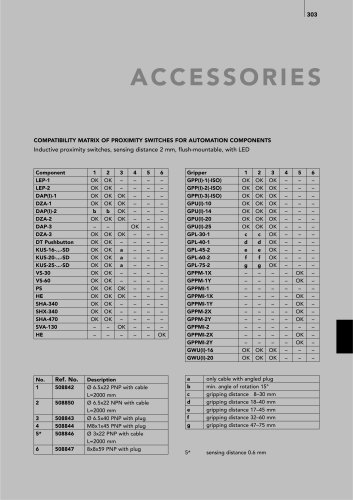

The inductive proximity switchesto be installed must fulfill the fol- lowing conditions: ֖ Switch gap 2 mm Flush-mountable ֖Minimum casing length (6.5 mm): GPE: 27 mm GWE: 19 mm GPEGWE Other Quick-Set elements are listed in our ثQuick-Set catalogue.SLL-20-40 Ref. No. > ۘ6.53.5 PNP ؘ 6.5 mm with LED, protection against short circuits and reverse pinconnection, switch gap 2 mm, flush mountable, Length L = 2000 mm 508842 > 22L pluggable M8x1 508843 > 6.5 31 40 for 3-pin proximity switch, highly flexible, screwable M8x1 > 1) L = 5 m, with socket straight on one side 504610 L = 5 m, with socket...

Open the catalog to page 17

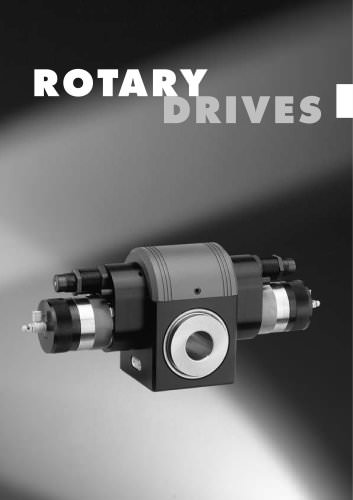

The electrical rotary unit DAE-60 is designed for rotational movements.Toothed belts and angular gears achieve a high transmission ratio resultingin high output torques. It is driven by a brushless, electronically commu-tated DC motor with integrated encoder. The built-in inductive proximity switch is for setting the zero point of the drive shaft for the reference run.The standard supplied cables are 3m long, internally wired and perma-nently fastened to the device with screwed cable glands and strain relief.The cables are attached to the supplied plug-in terminals of the...

Open the catalog to page 18All MONTECH catalogs and technical brochures

-

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

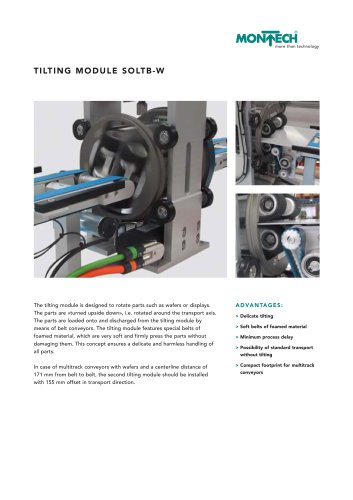

TILTING MODULE SOLTB-W�

2 Pages

-

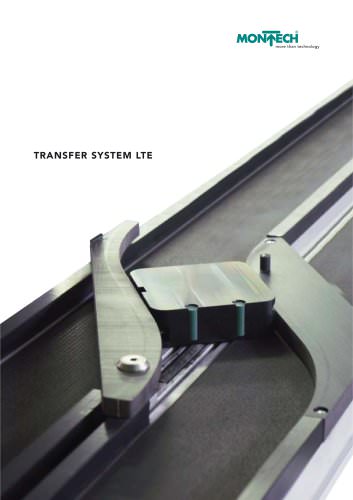

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

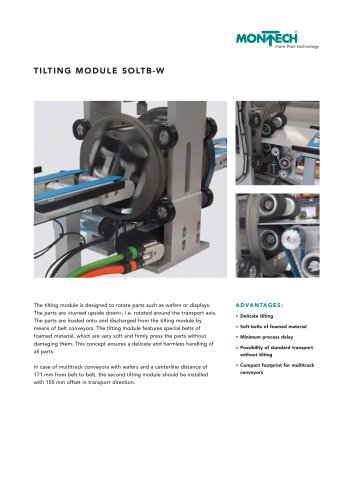

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

Automation – Accessories

6 Pages