Catalog excerpts

170 > COMPACT UNIVERSAL SLIDES KUS DESCRIPTION The Compact Universal Slide KUS has a robust design with veryhigh rigidity and a long life.At strokes of min. 20 mm to max. 240 mm, the maximum installationmass is 10 kg.In three sizes with piston diameters from 16 to 25 mm, four strokelengths are available. >

Open the catalog to page 5

171 Ball bearings Adjustable end stops (maximum absorption).Adjustable end stops (minimum absorption).Adjustment of the absorptionscrew. Stop adjustmentCage for ball synchronization. The high rigidity is achieved by ball bearings with a gothic profile.Ball synchronization is ensured by means of a cage with integratedlubricant reservoir.Hydraulic shock absorbers act as end stops.The absorption characteristics can be adapted to the application,guaranteeing an optimal cycle time.Both end stops are continuously adjustable by 20 or 40 mm,depending on the size. >

Open the catalog to page 6

172 Proximity switch for retractedposition.Proximity switch for extendedposition. Air connectionsDovetail mount and fixingbores.Compensating spring The two end positions can be detected with two inductive proximi-ty switches. In the case of a stroke adjustment, the proximityswitches dont need to be adjusted.Pluggable air connections with adjustable exhaust throttles at theback of the slide ensure optimum accessibility.For maximum installation flexibility, the slide has both Quick-Set > Ү dovetail mounts, threads and positioning holes on three sides. For vertical use, a compensating spring...

Open the catalog to page 7

173 > COMPACT UNIVERSAL SLIDES KUS SCOPE OF DELIVERY Compact Universal Slide with two hydraulic shock absorbers, two integrated holders for inductive proximity switches, two exhaust throttles with plug-type connection and a comprehensive operating instruction. > SUITABLE ACCESSORIES Special accessoriespage 186 Accessoriesfrom page 302(see also assembly instructions from page 176)Quick-Set > from page 338 Three sizes with piston diameter of 16, 20 and 25 mm. >

Open the catalog to page 8

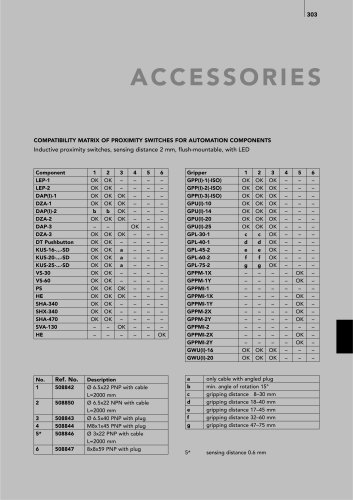

176 e.g. inserter with revolver head: > ASSEMBLY INSTRUCTIONS A KW-40 bracket with two SLL-55-40 clamping elements is used asan additional fixing element for the vertical KUS. When installing a projecting load (L > z direction) on the end plate, it is essential to provide additional fixingon the slide to prevent vibrations. Fixings of this type can be realized simply and quickly by using Quick- Set > elements. > SLL-55-40KW-40 KUSKUSSLL-55-40 Inductive proximity switches: The inductive proximity switch to be installed must fulfill the follow- ing conditions:Ζ Sensing distance:2 mm...

Open the catalog to page 11

186 > SPECIAL ACCESSORIESINSTALLATION KITS FOR COMPENSATING SPRING Tension spring with clamping bolt and two hexagon nuts for installa-tion for vertical application: Ref. No. Installation kit for compensating spring to KUS-16-20-SD 51631 Installation kit for compensating spring to KUS-16-40-SD 51632 Installation kit for compensating spring to KUS-16-60-SD 51633 Installation kit for compensating spring to KUS-16-80-SD 51634 Installation kit for compensating spring to KUS-20-40-SD 51635 Installation kit for compensating spring to KUS-20-80-SD 51636 Installation kit for compensating spring to...

Open the catalog to page 21All MONTECH catalogs and technical brochures

-

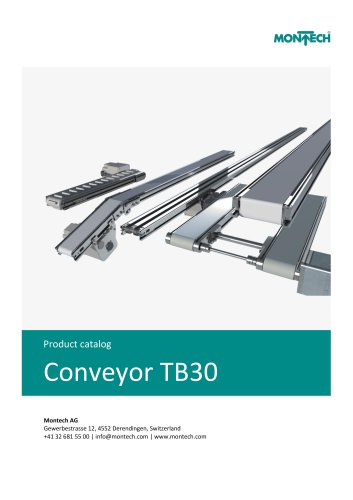

CONVEYOR TB30_2022

62 Pages

-

PROFILE SYSTEM QUICK-SET QS

68 Pages

-

SAFETY DEVICES

30 Pages

-

MAX CONVEYORS GTB

28 Pages

-

TB40 Conveyor

45 Pages

-

RB40 Roller Conveyor

18 Pages

-

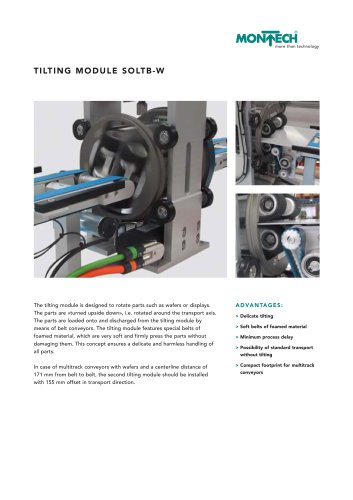

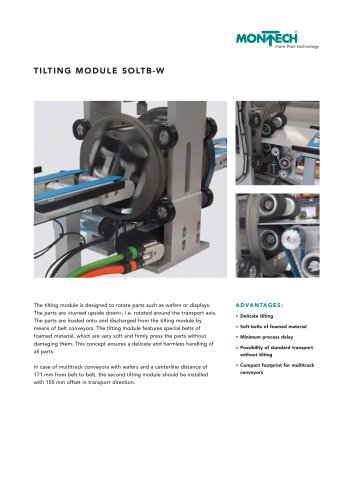

TILTING MODULE SOLTB-W�

2 Pages

-

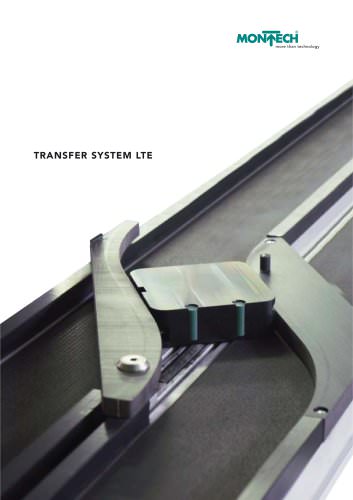

Transfer System LTE

52 Pages

-

Multitrack Conveyor MTB

2 Pages

-

Vacuum Conveyor SOLTB-V

2 Pages

-

Centering Conveyor SOLTB-Z

2 Pages

-

Short Conveyor SOLTB-K

2 Pages

-

Unloading Conveyor SOLTB-E

2 Pages

-

Removal Module SOLTB-ASM

8 Pages

-

Special Conveyor SOLTB

2 Pages

-

Conveyor TB40

24 Pages

-

Transport System LT40

40 Pages

-

Max Conveyors GTB

50 Pages

-

Conveyor for cleanrooms TBR

3 Pages

-

Conveyors TB

54 Pages

-

Basic Conveyors BTB

35 Pages

-

Minidrive Conveyors KTB

36 Pages

Archived catalogs

-

Tilting Module SOLTB-W

2 Pages

-

Conveyors Manual

154 Pages

-

Montrac Manual

100 Pages

-

Mounting System – Quick-Set

116 Pages

-

Conveyors – Transfer System LTE

52 Pages

-

The World of Conveyors

16 Pages

-

Automation – Linear units LEP

32 Pages

-

Automation – Grippers

63 Pages

-

Automation – Rotary drives DAP

34 Pages

-

Automation - Lifting Devices HE

11 Pages

-

Automation – Accessories

6 Pages