Catalog excerpts

“Setting The Standard For Supplier Excellence” Microwave Solids Flow Monitors M o d e l s S F D - 2 & SFI M Best Value In Solids Flow Detection Superior Application Versatility Excellent Sensitivity Indicate Flow/No-Flow In Chutes, Feeders and Pipelines On/Off Flow Detector (SFD-2) Analog Output Indicator (SFI) Hazardous Location Approval

Open the catalog to page 1

The SFD-2 and SFI use low power microwaves to sense motion within the chute or pipeline being monitored. Microwaves are virtually unaffected by ambient noise and light, heat, humidity, pressure, vacuum, high or low temperatures or dust. This provides maximum effectiveness in typical industrial application environments. These advantages over sonic or mechanical flow monitors make microwave technology the best choice for solids flow monitoring. Senses Light And Heavy Materials, Small And Large Particles Non-Contact Sensor Detects Flow Through Most Non-Metallic Surfaces Non-Intrusive Flush...

Open the catalog to page 2

TRANSCEIVER (SENSOR) M Powder coated Nema 4 cast aluminum construction Monitor’s Solids Flow Detector and Indicator can be used in a variety of applications to detect flow/no-flow conditions of powders and bulk solid materials. The selection of either SFD2 Solids Flow Detector or the SFI Solids Flow Indicator is based upon the type of output required (relay or analog). M Approved for Class II hazardous areas M Meets applicable FCC regulations M Screw-on/off cover Typical applications include: M Detection of a partial or full plug in a conveying line M Teflon ® process seal is standard M...

Open the catalog to page 3

STAINLESS STEEL ADAPTERS Four different mounting adapters can be used to provide a stainless steel process contacting surface. The adapter can be of either 1-1/2" NPT or Tri-Clamp ® food grade construction. GALVANIZED HALF-COUPLING Monitor provides a galvanized half-coupling which can be welded to the chute or pipe for mounting the transceiver. Half Coupling: P/N 17-3111 LOCKNUT The optional locknut provides flexibility in the depth of the mounting of the transceiver to ensure that the process seal is flush with the inside of the conduit in which the target material flows. Lock Nut: P/N...

Open the catalog to page 4

POWER SUPPLY OPTIONS 1 = Power Supply/ Cond.Board Only 2 = Power Supply/ Cond. Board in Fiberglass Enclosure with Lights SEALS 1 = Teflon ® 2 = Ryton ® SEALS 1 = Teflon ® 2 = Ryton ® SENSOR APPROVALS 1 = Hazardous Locations (North America) (Sensor ONLY) SENSOR APPROVALS 1 = Hazardous Locations (North America) OPERATING VOLTAGE 1 = 24 VDC (15-30 VDC acceptable) OPERATING VOLTAGE 1 = Universal 100-240VAC( ±10%) ACCESSORIES Locknut for securing housing in mounting coupling 17-3305-1 Saddle Coupling with Gasket Half Coupling, Galvanized Steel 17-3305-3 Adapter, T304 S.S., 1-1/2" NPT, Teflon ®...

Open the catalog to page 5

TRANSCEIVER (SENSOR) Power Requirement: SFD-2 SFI Enclosure: Enclosure Protection: Ambient Operating Temperature: SFD-2 SFI Process Temperature: Process Seals: Pressure Ratings: Process Connection: Conduit Connection: Detection Range: Sensitivity: Minimum Velocity: Output: SFD-2 SFI Isolation (SFI Only): Indicators: Emission: Approvals: Provided by power supply/conditioning PCB 15-30VDC, 100mA max. Die-cast aluminum, beige polyester powder coated NEMA 4, IP66 -40˚ to +185˚ F (-40˚ to +85˚ C) -13˚ to +185˚ F (-25˚ to +85˚ C) 250˚ F (121˚ C) if ambient air temp. below 150˚ F (65˚ C) TFE...

Open the catalog to page 6

Monitor Technologies LLC warrants each SFD-2/SFI it manufactures to be free from defects in material and workmanship under normal use and service within two (2) years from the date of purchase. The purchaser must give notice of any defect to Monitor within the warranty period, return the product intact and prepay transportation charges. The obligation of Monitor Technologies LLC under this warranty is limited to repair or replacement at its factory. This warranty shall not apply to any product which is repaired or altered outside of the Monitor Technologies LLC factory, or which has been...

Open the catalog to page 7

44W320 Keslinger Road T P.O. Box 8048 T Elburn, IL 601 19-8048 T 800-766-6486 T 630-365-9403 T Fax 630-365-5646 www.flexar.info T www.monitortech.com T www.monitortech.typepad.com T monitor@monitortech.com

Open the catalog to page 8All Monitor Technologies catalogs and technical brochures

-

TC-1 & TC-3

2 Pages

-

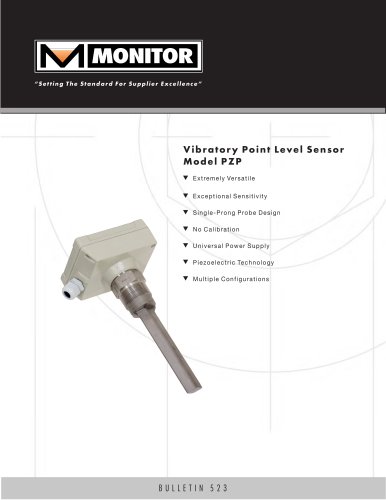

PZP Vibratory Level Probe

4 Pages