Catalog excerpts

APPLICATION TOOLING General Information Crimp Tooling Asia Pacific Morth Crimp Tooling access more part numbers download sales drawings, ___ product specifications, B~% t ft M ^^^f 3D models, place sample ■ ■ ■ \J ■ requests, and more. one company > a world of innovation

Open the catalog to page 1

General Information Introduction to Crimp Technology Developed to replace the need to solder terminations, crimping technology provides a high quality connection between a terminal and a wire at a relatively low applied cost. The methods for applying crimp terminations depend on the application and volume, and range from hand-held devices to fully-automated systems. The application methods include a basic hand tool, a press and die set, a stripper crimper or a fully automatic wire processing system. But no matter what method is used, the setup of each tool is critical for achieving a...

Open the catalog to page 2

Introduction to Crimp Technology Terminology (Continued) Extrusions (Flash) These are the small flares that form on the bottom of the conductor crimp resulting from the clearance between the punch and anvil tooling. If the anvil is worn or the terminal is over-crimped, excessive extrusion results. An uneven extrusion may also result if the punch and anvil alignment is not correct, if the feed adjustment is off, or if there is insufficient/ excessive terminal drag. Insulation Crimp (Strain Relief) This is the part of the terminal that provides both wire support for insertion into the housing...

Open the catalog to page 3

Introduction to Crimp Technology Shut Height The distance, at bottom dead center on a press, from the tooling mounting base plate to the tooling connection point on the ram of the press. Associated Materials Caliper A gauge, consisting of two opposing opposing blades, for measuring linear dimensional attributes. Application Tooling Eye Loop A magnification tool, normally 10x power or greater, which is used to aid visual evaluation of a crimp termination. Crimp Micrometer This is a micrometer specifically designed to measure crimp height. The measurement is taken in the center of the crimp...

Open the catalog to page 4

Insulation Displacement Technology Tooling Introduction Insulation Displacement Technology (IDT) is a wire termination technique in which an insulated wire is pressed into a terminal slot smaller than the conductor diameter, displacing the insulation and forming an electrical contact between the terminal and conductor. Insulation displacement offers 3 major advantages over other termination techniques: • Electrical connectors are supplied to the customer with the terminals loaded into their final positions. This feature results in customer labor savings as additional operations are not...

Open the catalog to page 5

Molex Crimp Tooling Within the family of Molex Crimp Tooling there are three levels: • Manual Crimp Hand Tools • Semi-Automatic Crimp Presses and Tools • Fully-Automatic Crimp Wire Processor Tools Manual Crimp Hand Tools These products are used for prototype and field repair work. These tools are not designed for production work. Application Tooling Type 2 • Advanced ergonomic design with superior mechanical gain and lower handle forces which increases productivity • High-strength, through-hardened alloy steel construction • Ratchet with safety release that ensures consistent performance •...

Open the catalog to page 6

Industry standard air-feed crimp press is ideal for descrete wire and cable applications Molex’s TM-3000 Universal Crimp Press provides an effective method of applying a wide range of side and rear-feed terminals to pre-stipped discrete wire and cable. The TM-3000 press is an inexpensive, electrically-controlled, direct-drive press designed for mid-volume, semi-automatic bench operations. This industry standard press will accept the most common industry standard applicators in the market place, thereby reducing tooling costs and providing production flexibility. This Molex air-feed crimp...

Open the catalog to page 7

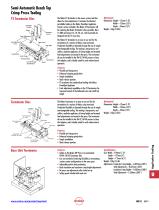

Semi-Automatic Bench Top Crimping Presses Features • Utilizes Molex Base Unit and TM-40/42 Terminator Dies and notching dies • Meets OSHA safety and noise requirements • Includes external work lamp • Minimum electrical and mechanical maintenance • Used 3BF Presses can be purchased on a rebuild basis only and are subject to availability Specifications Size without Reel Arm: Width—711mm (28") Current—5.5A Tonnage: 26.7kN (3 tons) 10 AWG Stroke Length: 38.10mm (1.500”) Shut Height: Adjustable Rate: Up to 2500 terminations per hour, dependent on operator speed and application Note: 3BF...

Open the catalog to page 8

Semi-Automatic Bench Top Crimp Press Tooling Matrix Active Semi-Automatic Press and Active Tooling Matrix Molex T2 Terminator Active Molex Terminator Active Molex FineAdjust Applicators Active Molex Mini-Mac Applicators Active Industry Standard Applicators Inactive Semi-Automatic Press and Active Tooling Matrix Molex T2 Terminator Active Molex Terminator Active Molex† Standard Die Inactive Molex FineAdjust Applicators Active Molex Base Unit Adapter Active Application Tooling Molex T2 Terminator Active Molex Mini-Mac Applicators Active Industry Standard Applicators *Inactive means Molex no...

Open the catalog to page 9

Semi-Automatic Bench Top Crimp Press Tooling FineAdjust Applicator Insulation Cam Conductor Cam Drag Frame Feed Finger Track Adjustment Base Plate The Molex FineAdjust Applicator is an improved version of the Molex Mini-Mac Applicator. The FineAdjust will be replacing the Mini-Mac where possible. Most 14 AWG and lower (16, 18, 20, etc.) will be designed into the FineAdjust Applicator over time. Features • Fine adjustment allows users to achieve target with little effort by adjusting on increments of 0.15mm (.0006") for conductor crimp height and .063mm (.0025") for insulation height •...

Open the catalog to page 10

Semi-Automatic Bench Top Crimp Press Tooling Insulation Punch Striker Conductor Punch Track Adjustment Back Track Adjustment Front Drag Frame Rear Cover Wire Stop Front Cover Terminal Track Cut Off Plunger and Retainer Anvil Mount Terminator Dies Insulation Punch Striker Track Adjustment Back Conductor Punch Feed Finger Track Adjustment Front Rear Cover Wire Stop Drag Finger/ Anti-Back Up Finger Terminal Track Cut Off Plunger and Retainer Anvil Mount Anvils Base Unit Terminator The Molex T2 Terminator is the newer version tool that allows for track adjustment. It contains the identical...

Open the catalog to page 11All Molex catalogs and technical brochures

-

Pre-Crimped Leads

4 Pages

-

HDMI Type-A Connectors

2 Pages

-

Brad® MX-PTLtm M12

2 Pages

-

Premo-Flex Hot Bar Soldering

2 Pages

-

Premo-Flex FD19

2 Pages

-

SlimStack

11 Pages

-

mPm

4 Pages

-

Brad Nano-Change

3 Pages

-

Strain-Relief Cord Grips

2 Pages

-

Outlet Boxes

3 Pages

-

Combo Antennas

2 Pages

-

MTP* /MPO ADAPTERS

11 Pages

-

DATA CENTER OPTICAL ASSEMBLIES

14 Pages

-

Molex Switch Products

1 Pages

-

Non-Magnetic

1 Pages

-

Vacuum

2 Pages

-

FCT Catalog

490 Pages

-

Crimp Flange

1 Pages

-

Cable Assembly

2 Pages

-

Fiber Optics

6 Pages

-

HBMT ™

1 Pages

-

Array-BeamTM

2 Pages

-

Woodhead® Product Catalog 37

358 Pages

-

C-Grid® and SL?

66 Pages

-

Milli-Grid?

69 Pages

-

KK® Product Overview

47 Pages

-

Storage Connectors

20 Pages

-

Processor and IC Sockets

3 Pages

-

Memory Module Sockets

6 Pages

-

Edge Card Connectors

8 Pages

-

Memory Card Connectors

6 Pages

-

Modular Plugs and Jacks

24 Pages

-

Transportation Products

56 Pages

-

Backplane Products

48 Pages

-

FFC/FPC Connectors

34 Pages

-

Power Connectors

115 Pages

-

Pitch PCB and Wire Connectors

64 Pages

-

Brad® mPm® DIN valve connectors

48 Pages

-

I/O Products

94 Pages

-

RF/Microwave Coaxial Products

43 Pages

-

Printed Circuit Products

11 Pages

-

Fiber Optic Products

27 Pages

-

Industrial Products

78 Pages

-

Brad® Automation Catalog

447 Pages

Archived catalogs

-

Profibus Selection Guide

10 Pages

-

BradConnectivity Selection Guide

24 Pages

-

Ethernet Selection Guide

12 Pages

-

Cable Grips

36 Pages

-

Portable Outlet Boxes

22 Pages

-

Wiring Devices

86 Pages

-

Portable Lighting

39 Pages

-

Brad Harrison Passive Media

24 Pages

-

Pushbuttons, Instruments

14 Pages

-

Electric Cord and Cable Reels

18 Pages

-

Ethernet products

26 Pages

-

Profibus products

40 Pages

-

DeviceNet products

68 Pages