Catalog excerpts

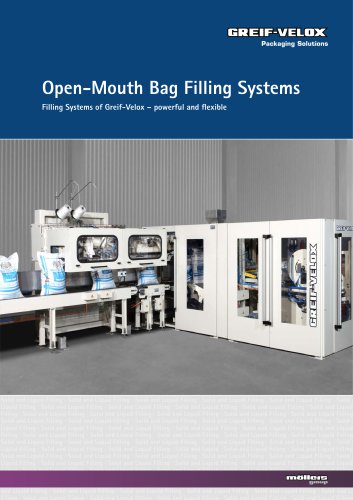

Valve Bag Filling Systems Filling Systems of Greif-Velox – an all-round clean package Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid a Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid a Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid a Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid · Solid and Liquid Filling · Solid and Liquid Filling Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid a Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid a Liquid Filling · Solid and LiquidSolid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling · S and Liquid Filling · Solid and Liquid Filling · Solid and Liquid Filling ·

Open the catalog to page 1

German engineering – globally in use. This makes the filling of valve bags efficient and economically advantageous From a single bagging unit to a complete logistics solution. Our valve bag filling system will match your needs Good engineering for good results We offer you the best suitable bag filling system to your capacity demand. The modular design with one to six filling spouts and a maximum capacity of 1600 bags/h let the machines master various bagging volumes. Greif-Velox systems use pneumatic packer, impeller packer, gravity-type packer and vacuum packer - depending on the product...

Open the catalog to page 2

packaging solutions Supplementary components The bagging plants can be completed with accessories for automated empty bag placing and valve welding for hermetic bag closure. A wide range of equipment for inspection and marking does top off the supply such as sample takers, metal detectors or check weighers for inspection and labelers or ink-jet systems for marking. • Greif-Velox delivers your bagging system optimized to your needs. • Use of proven machine components. • Expandability and optimal room use by individual engineering. ... to an all-round clean package.Filling systems for valve...

Open the catalog to page 3

German engineering – globally in use. Free-flowing, sticky, adherent, bridging products, finest powder, granular products or stones: For each product the right filling technology Pneumatic packer type BVP Pneumatic packer type BVPV BVP for the filling of light and powdered media of 30 µ to 5 mm. BVPV for the filling of heavy and granular products as well as mixed products of 50 µ to 12 mm. • p to 350 bags/h per packer unit, up to 6 in-line packers u • p to 400 bags/h per packer unit, up to 6 in-line packers u automatic control of conveying air, own air compressor and flexible lining...

Open the catalog to page 4

Gross weighing gravity packer BVR BVR for free-flowing granular products • weighing ranges 10 - 30 kg / 12,5 - 50 kg • up to 100 bags/h per packer unit For manually placed valve bags without additional sealing. Net weighing gravity packer NVR NVR for free-flowing grainy or granular products • weighing ranges 10 - 30 kg / 12,5 - 50 kg • up to 600 bags/h per packer unit For manually or automatically placed valve bags with our without additional sealing. Gross weighing vacuum packer VELOVAC Dust-free filling of extremely light bulk solids of low density as for instance fumed silica, pigments...

Open the catalog to page 5

German engineering – globally in use. Automatic Bag Placer VALVOMAT Greif-Velox‘ VALVOMAT automatically places valve bags on up to four in-line spouts at a maximum rate of 1000 bags/h. No adjustments are necessary to handle both paper or plastic bags nor for varying bag and valve widths. The VALVOMAT is applicable for bag lengths from 380 to 900 mm and bag widths from 380 to 700 mm. Each valve bag placer system includes an empty bag magazine, optionally available with bag singling for label application

Open the catalog to page 6

With filling systems of Greif-Velox you are optimally prepared by all means Special tasks call for special equipment – or additions Valve bag sealing VALVOSEAL The VALVOSEAL of Greif-Velox provides a reliable closure immediately after filling. That means no dust escape at discharge and further transport of the bag. The ultrasonic welding is applicable for paper and plastic bags and safe in dust-Ex areas too. To protect against hazardous dust in the filling area or to protect the product against environmental effects, Greif-Velox offers completely encased installations. The filling area may...

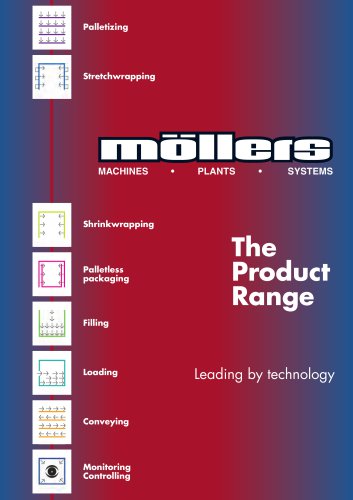

Open the catalog to page 7All Möllers catalogs and technical brochures

-

HSB-2600

4 Pages

-

2in1 Series_2022

13 Pages

-

HSA-Vario

16 Pages

-

Seminare

16 Pages

-

PLS-C

16 Pages

-

PSH-1 / PSH-2 / PSH-Vario

12 Pages

-

Automatic stretch hooder

16 Pages

-

Bag Loading Systems

11 Pages

-

Full Line. High Quality.

32 Pages

-

FIBC Filling Systems

6 Pages

-

Palletizing Systems

16 Pages

-

Palletless Packaging Lines

16 Pages

-

R&D Center

9 Pages

Archived catalogs

-

2in1 Series_2011

13 Pages