Solutions for the chemical and petrochemical industry. Innovative. Individual. High-Performance.

32Pages

Catalog excerpts

Solutions for the chemical and petrochemical industry. Innovative. Individual. High-Performance. Purple – the Colour of Innovation.

Open the catalog to page 1

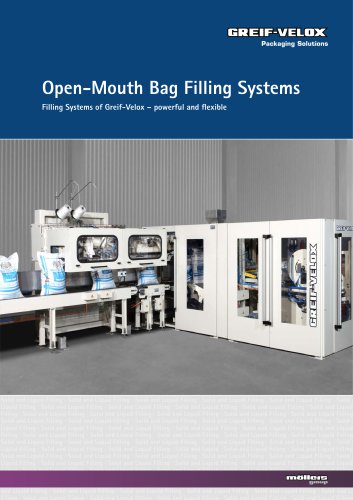

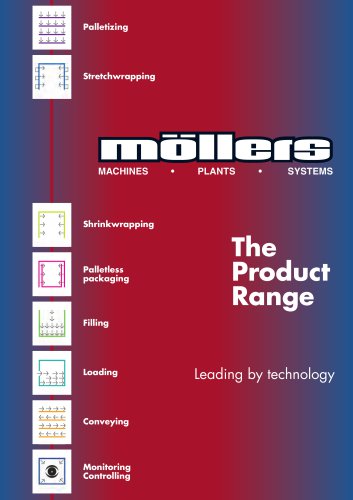

MÖLLERS GROUP: TECHNOLOGY LEADER WITH A HEAD-START ON EXPERIENCE. Full Line – High Quality since 1952: Möllers Group develops and manufactures plant and machinery for the entire spectrum from material filling through palletizing and packaging to loading. With production facilities in Beckum, in the USA, in Lübeck and associate companies in Russia, Singapore as well as worldwide representatives and agents in all important industrial locations, Möllers Group is well-positioned internationally and is the leader in many of its product secto

Open the catalog to page 2

Introduction Where much is expected, competence, experience and innovative strength count. Möllers Group Full Line. High Quality. Engineering and Project planning Progress through competence – right from the start. Solved efficiently – from enquiry to turnkey. Bagging Reliable total solution for dosing, weighing, filling, and closing of containers. Precise filling for chemicals and petrochemicals. Palletizing Expertly palletized. Securely transported. Robot solutions for palletizing and depalletizing. Wrapping Hood stretch technology: Packaged with film. Dispatched with security. Shrinking...

Open the catalog to page 3

Where much is expected, … ... competence, experience and innovation count. The chemical and petrochemical industry is not only unique in its broad product range, but also in the demands which prevail in the handling of filling, packaging and loading processes. With the often highly-sensitive products suppliers need to depend on reliable plant and machinery solutions which individually adapt to the challenges in hand – be they Product factors such as high temperatures, variable bulk densities, different particle sizes and flow characteristics or contamination or Context factors such as...

Open the catalog to page 4

MÖLLERS GROUP Full Line. High Quality. Individual solutions which are specially tailored to your sector. Total solutions which guarantee economic, smooth-running production procedures. Quality which is not only first-class, but offers everything you need – and all from a single source. The ”Full Line – High Quality“ Möllers Group concept represents this every day worldwide in a thousand applications. Success down the whole line ... Möllers Group unites the most important capabilities for the chemical and petrochemical industry under one brand: from advice, planning and design, through...

Open the catalog to page 6

... meets quality with security. We know: the chemical and petrochemical industry is a sector which demands an extreme degree of attentiveness and precision of its As an experienced partner to the chemical and petrochemical sector, we support you with the same degree of sense of responsibility which characterizes your daily work. We help you to maximize machinery lifetimes within the entire filling, palletizing, packaging and loading process - for greater economy across the entire process line. Customer-oriented, rapid to respond and flexible: We're glad to be there for you! Machines ■...

Open the catalog to page 7

ENGINEERING & PROJECT PLANNING PROGRESS THROUGH COMPETENCE – RIGHT FROM THE START. At Möllers, innovation has a colour – and a motto: Purple – the Colour of Innovation. Every day we design and realize new, innovative solutions for our custom

Open the catalog to page 8

ENGINEERING & PROJECT PLANNING How high the priority of the factor ”power of innovation“ is in our group of companies is also vouched for by the ever increasing number of patents which are accredited to us throughout Germany, but also in Europe and beyond, as well as for the American market. As our customer this means for you: With every Möllers Group plant and machine you profit from our know-how gained over decades. And you can rely on a tailor-made solution which is exactly that: tailored to your needs. Control and visualization technology by Möllers Group: Systematically structured....

Open the catalog to page 9

ENGINEERING & PROJECT PLANNING SOLVED EFFICIENTLY – FROM ENQUIRY TO TURNKEY. As an integral constituent of modern industrial processes, filling and packaging equipment must function reliably. Its high availability and smoothly-running operation make a decisive contribution to the economics of the process chain. The prerequisite for this: qualified plant-engineering. From enquiry to solution: Each machine and plant component which we develop for you has a secure basis: the unique know-how of our project engineers and designers. Profit from engineering capabilities which think ahead – and...

Open the catalog to page 10

ENGINEERING & PROJECT PLANNING Also all further steps up to completion of your machinery technology are optimally matched to one another and are performed with maximum efficiency. Our capabilities for you commence with ascertaining your specific plant requirements and set the course for our cooperation. This finds its successful conclusion in the handover and commissioning of your turnkey packaging line – from a single mould and in premium quality which we are responsible for as total supplier. Möllers Group Engineering – your benefits: dependable construction flexible solutions ...

Open the catalog to page 11

RELIABLE TOTAL SOLUTIONS FOR DOSING, WEIGHING, FILLING AND CLOSING OF CONTAINERS. The complexity of filling procedures in the chemical and the petrochemical industry is high: Varying bulk densities, flow characteristics and viscosities demand continuous, precisely functioning machinery for the entire process of dosing, weighing, filling and closing. FFS – Form Fill and Seal filling system

Open the catalog to page 12

With a broad spectrum of filling machines for bulk materials and liquids, Möllers Group has adapted itself to the special needs of the chemical and petrochemical industry. Filling machines for bulk materials Chemical bulk materials are positioned in the range of 0.03 kg/dm³ to 2.0 kg/dm³ and at a particle grain size of 20 μ to 10 mm. They can be toxic, explosive, abrasive or aggressive and possess varying flow characteristics. On custumer request, Möllers Group develops the optimum filling machine for each application whilst taking into consideration product characteristics and packaging...

Open the catalog to page 13All Möllers catalogs and technical brochures

-

HSB-2600

4 Pages

-

2in1 Series_2022

13 Pages

-

HSA-Vario

16 Pages

-

Seminare

16 Pages

-

PLS-C

16 Pages

-

PSH-1 / PSH-2 / PSH-Vario

12 Pages

-

Automatic stretch hooder

16 Pages

-

Bag Loading Systems

11 Pages

-

Full Line. High Quality.

32 Pages

-

FIBC Filling Systems

6 Pages

-

Valve-Bag Filling Systems

8 Pages

-

Palletizing Systems

16 Pages

-

Palletless Packaging Lines

16 Pages

-

R&D Center

9 Pages

Archived catalogs

-

2in1 Series_2011

13 Pages