Catalog excerpts

Transport security for valuable goods

Open the catalog to page 1

Palletized loads protected by shrink film for transport Palletized goods are exposed to large forces of acceleration during transportation and handling, and must be protected against distortion, interlocking with adjacent loads or collapse of the load. In many branches of industry throughout the world shrinkpackaging of pallets has proved to be a highly reliable and adaptable method for protecting the most varied industrial goods. Protecting pallets with shrink film is an environmentally friendly and, at the same time, an economical method: minimum use of multiple recycable packing...

Open the catalog to page 2

The universal model range of the Mollers tubular film wrapping machines offers the possibility to select the machine according to the output requirements and local situation of the packaging plant. Also the option to use two or even three types of film in succession is a part of the system flexibility which offers the client the efficiency of the investment in the future. It is possible to change the width of the tube or the thickness of the film as well as to select between different printedor coloured films.

Open the catalog to page 3

Safety electric shrink frame The type of shrink film heater most used at present is the shrink frame, which is characterized by its rapid readiness for service. Electric shrink frames also offer the advantage of not giving off any combustion gases; they are therefore used wherever gas-heating is not permitted on safety grounds or is not wanted. Mollers safety electric shrink frames are also designed for low energy consumption and fulfill the strictest safety requirements. The optionally deliverable explosionproof model can also be used in spaces where the surrounding air is...

Open the catalog to page 6

The Mollers fully automatic tubular film wrapping . machine, type gas-heated Combi-FSA, combines the tubular film wrapping machine with the Mollers safety gas-heated shrink frame as spacesaving, failsafe unit. The also hereby applied enclosed thermal shrinking system with vertical heat guiding system and tem-peratuc monitoring fulfills highest safety requirements. The gas-heated shrink system is characterized by its rapid heating-up process and allows even in the compact design high average outputs of up to 100 pallets/h. All Mollers Combi-FSA machines can be fitted with the patented...

Open the catalog to page 9

Mollers engineers have been dealing with the technology of palletizing and protecting pallets for transport for decades during which they have gathered extensive know-how in the use of film of packaging. The wide experience they have accumulated also forms the basis for the development of the Combi shrink- / stretchpackaging technology which, with their great number of possible combinations, ensure high user flexibility. Combi shrink-/stretchwrapping systems can provide palletized loads with shrink or stretch hoods, and can also make up palletless despatch units with the Mollers Reverse...

Open the catalog to page 11

The economic and environmentally friendly palletless shrink wrapped package according to the Mollers Reverse Hood Shrinkwrapping System is everything in one - despatch unit, secure for transport and protection against weather. Reverse hood shrinkwrapped packages consist ex-# clusively of the loading good and the shrink film hood, which is formed out of two hoods, the inner hood and the reserve hood. The hoods tighten the stacked packing units together and form a stable and self-supporting load unit which can be handled without any problems with fork lift trucks and cranes. Reverse hood...

Open the catalog to page 13

Sleuerung Fin Schrmnpfprozeft gestarlet For the operator the important characteristics of the plant control system are the clearly laid out process structure, the simple operating procedures with minimum need for intervention, the ability to examine the process operation at any time, and the system-integrated support with functions for maintaining plant availability. Mollers has the perfect answer to all these requirements by using process display systems which show the plant operator the current operating status, assist any operator interventions which may be necessary by...

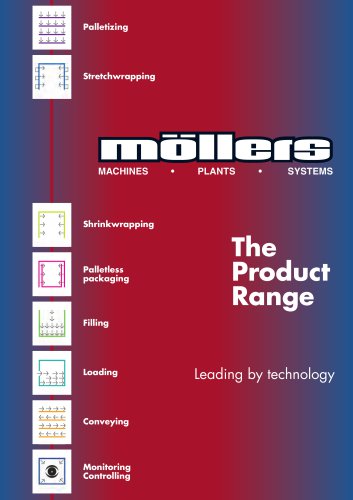

Open the catalog to page 15All Möllers catalogs and technical brochures

-

HSB-2600

4 Pages

-

2in1 Series_2022

13 Pages

-

HSA-Vario

16 Pages

-

Seminare

16 Pages

-

PLS-C

16 Pages

-

PSH-1 / PSH-2 / PSH-Vario

12 Pages

-

Automatic stretch hooder

16 Pages

-

Bag Loading Systems

11 Pages

-

Full Line. High Quality.

32 Pages

-

FIBC Filling Systems

6 Pages

-

Valve-Bag Filling Systems

8 Pages

-

Palletizing Systems

16 Pages

-

Palletless Packaging Lines

16 Pages

-

R&D Center

9 Pages

Archived catalogs

-

2in1 Series_2011

13 Pages