Catalog excerpts

Palletless Packaging Lines using the Möllers reverse hood stretch / shrink wrapping system Palletless packaging Palletless reverse hood packages – the cost saving transport unit

Open the catalog to page 1

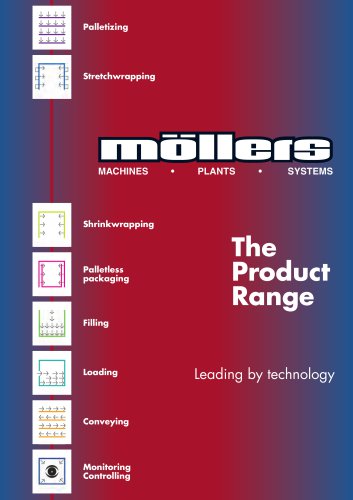

Palletless packaging Filling, palletizing, packaging, loading. The entire process from a single source . . . The palletless despatch unit – now a choice between: STRETCH- or SHRINK-wrapped ! It started with a visionary idea - eliminating the transport pallet by using the goods themselves as the load platform – the idea of the self-supporting despatch unit, robustly braced within a sealed enclosure of shrink film. Möllers engineers developed the reverse hood shrink system, and brought the new technology to market. The reverse hood shrink wrap load has proved its worth in countless...

Open the catalog to page 2

Plant engineering THE PALLETLESS DESPATCH UNIT using the 1 1 1 11J 1 LirJ fczd REVERSE HOOD . STRETCH / SHRINK , >_ t The transport pallet has undoubtedly become an indispensable element in rationalizing the supply chain and distributing goods efficiently. But the pallet is a costly logistics tool. Whether they are disposable pallets or a reusable ones, pooled pallets or your own, the procurement costs are high. Then there are significant costs for transporting and storing empty pallets. Inventory managment and pallet repairs involve additional cost, which is often significant. The...

Open the catalog to page 3

Palletless packaging Filling, palletizing, packaging, loading. The entire process from a single source . . . There are five steps in the production of a palletless stretch package 1. Goods stacked. Last layer (top layer) in a reduced stacking pattern 2. Base film applied THE DOUBLE CLAMP STRETCH 3. Inner hood drawn into position 4. Load turned through 180° The top layer now forms the base of the load 5. Reverse hood drawn into position. Load is ready for despatch The ultimate in reverse hood technology New advantages of the palletless stretch-wrapped load The energy-saving palletless...

Open the catalog to page 4

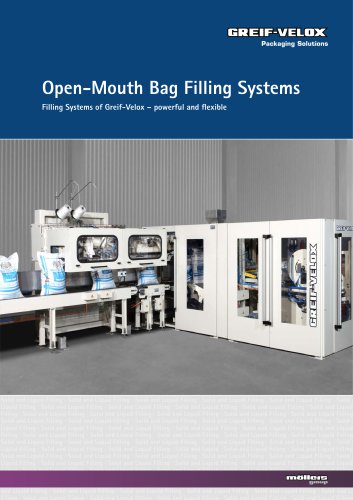

Roto-Packers and in-line packers for paper and plastic valve bags Reverse hood stretch loads are …. ... rugged for shipping by road, rail or sea ... ideal for bags and other containers, ... even for high loads and heavy weights ... suitable for transport on open vehicles, with fast loading and unloading ... storable outdoors in all weathers, ... even at the consignee (customer benefit that can be marketed by the supplier) . . . ... optimized for minimum film consumption ... made of environment-friendly recyclable material Flexible in use, secure investment Reverse hood stretch packaging...

Open the catalog to page 5

Palletless packaging Filling, palletizing, packaging, loading. The entire process from a single source . . . Six steps to prepare a palletless shrink-wrapped load for shipping 1. Goods stacked. Last layer (top layer) with reduced pack pattern 2. Inner hood drawn into position THE DOUBLE CLAMP SHRINK 3. Fork niches profiled on both sides of the top layer 4. Load turned 180". The top layer now forms the base of the package 5. Reverse hood drawn over 6. Fork niches reformed. The unit is ready for shipping The mother of all palletless film wrapped loads: Maximum freedom of choice with the...

Open the catalog to page 6

FFS bag filling machines, Pneumatic packers, Vacuum packers, Screw packers, Dump weighers, Open-mouth bag filling lines Tailor-made machines – flexible operation Möllers reverse hood shrink-wrapping lines are available with a capacity ranging from 20 to 90 packages per hour. Above: 1 Wrapping the inner shrink hood over the load 2 Forming the fork niches in the inner hood 3 Reforming the fork niches in the reverse hood Shrink-wrapping line PKS-1with integrated shrink frame By combining various film thicknesses and load cover formats with full-size or shortened reverse hoods, with a light...

Open the catalog to page 7

Palletless packaging Filling, palletizing, packaging, loading. The entire process from a single source . . . Warehousing free of charge: Reverse hood packages can be stored outdoors Open-air storage for reverse hooded loads is variable in size, pattern and position, and rapidly available as required The product is sealed tight in reverse hood loads, excluding moisture. This eliminates the harmful effect of water and atmospheric humidity. This functionality soon earned the reverse hood wrapped load a second role, enabling product to be stored in the open. A flat surface is sufficient; there...

Open the catalog to page 8

Automatic Palletizers Speedy loading of trucks and railcars: Reverse hood unit loads get moving Reverse-hood packages are resistant to the rigours of handling and transport. The tough film cover robustly encloses the goods, retains the shape of the load, and resists loading and unloading stresses. The tightly sealed unit loads thus provide a further advantage of this unique type of packaging: reverse hooded loads can be transported on open vehicles, since they are weather resistant. Open loading platforms of trucks and railcars are faster to access; many users have been pleased to find the...

Open the catalog to page 9

n~nm i ithus MACHINES • PLANTS • SYSTEMS Filling, palletizing, packaging, loading. The entire process from a single source . . . Reduced loading times cuts anchorage charges: Reverse hood packages get sea freight going Reverse hood shrink-wrapped loads have proved the ideal form of sea freight. Compared to loading loose bags in sling hoists, they can achieve many times the loading and unloading rate with fully mechanized handling, thanks to their greater volume, precise, stowable shape with high stack pressure resistance. Reduced loading times also cut port turnaround times and demurrage...

Open the catalog to page 10

Combi-FSA Shrink-wrapping machines Even after long and arduous journeys: Reverse hood packages arrive in good shape Sea voyages are not always gentle. But a well stowed cargo should be able to withstand rough seas. Reverse-hood packages satisfy this requirement, with all the features needed to arrive safe and sound – regardless of how often they are handled, the means of transport and the distances involved. Economical and environment-friendly Changing climatic conditions – cold and heat – have no significant effect on the transport and storage characteristics of the unit loads. Transport...

Open the catalog to page 11All Möllers catalogs and technical brochures

-

HSB-2600

4 Pages

-

2in1 Series_2022

13 Pages

-

HSA-Vario

16 Pages

-

Seminare

16 Pages

-

PLS-C

16 Pages

-

PSH-1 / PSH-2 / PSH-Vario

12 Pages

-

Automatic stretch hooder

16 Pages

-

Bag Loading Systems

11 Pages

-

Full Line. High Quality.

32 Pages

-

FIBC Filling Systems

6 Pages

-

Valve-Bag Filling Systems

8 Pages

-

Palletizing Systems

16 Pages

-

R&D Center

9 Pages

Archived catalogs

-

2in1 Series_2011

13 Pages