Catalog excerpts

Palettieranlagen englisch, ohne Textfarbe:Layout 1 Palletizing Systems Standard for economy and reliability in palletizing technology

Open the catalog to page 1

Palettieranlagen englisch, ohne Textfarbe:Layout 1 Filling, palletizing, packaging, loading. The entire process from a single source . . . When palletizing, economy and reliability set the standard. For this reason investments in top quality are not a luxury: Palletizing plants from Möllers Investment decisions on solid ground Top quality palletizing machines must process large volumes of packaging goods at high speed whilst treating sensitive goods with the utmost care and form exactly formed, stable pallet loads. Top quality palletizing machinery can be recognized by its suitability to...

Open the catalog to page 2

Palettieranlagen englisch, ohne Textfarbe:Layout 1 Plant engineering PLS, PFS, PGS & Co. – in detail and better overall: Möllers palletizers are tailored in every detail and in the sum of its capabilities to the multitude of demands in practice Plant-Engineering: Planned safety Palletless dispatch units: Maximum efficiency At the outset meticulous design, thereafter the overall supply and the installation, to hand-over – that is Möllers-Plant-Engineering, basis of perfect plant function. With application experience in numerous sectors we secure the long-lasting success of packaging...

Open the catalog to page 3

Palettieranlagen englisch, ohne Textfarbe:Layout 1 Filling, palletizing, packaging, loading. The entire process from a single source . . . Basis of perfectly tailored packaging plants: Palletizers with modular design Möllers palletizing machines are manufactured using modular design. This principle is the basis of perfect adaptability of the machines to the required throughput rates, to the type and to particular characteristics of the goods to be palletized and to operational fields of use. The high degree of extendability is at the same time one of the foundations for the erection of...

Open the catalog to page 4

Palettieranlagen englisch, ohne Textfarbe:Layout 1 In-line packers, 2 to 6 filling spouts Layer formation Example: 5-bag-layer Gentle, shock-free formation and layer transfer: Stable pallet loads are formed in this manner Möllers palletizing machines take care of the great susceptiblity to deforming of many packed goods thanks to their special method of operation. Buckling, tears and bulges must also be avoided at high operating speeds, so that exactly stacked, stable pallet loads are created. Significant components for this, in tailored combinations: Optionally employable turning devices:...

Open the catalog to page 5

PLS-C - The chemical palletizers . . . In the right format at a mouse click In the bulk material-producing industrial sectors the most various bag formats are used from which various packing patterns result. The typical module design of Mollers palletizers makes variable tailoring of the machines to predetermined packed-goods formats and pallet sizes possible. The most frequent bag lengths lie between 400 and 1100 mm, usual bag widths between 275 and 550 mm. The selection from the stored bag formats in the program and the ancillary layer patterns, as well as possibly assigned pallet sizes,...

Open the catalog to page 6

Palettieranlagen englisch, ohne Textfarbe:Layout 1 FFS bag filling machines, Pneumatic packers, Vacuum packers, Screw packers Dump weighers, Open-mouth bag filling lines to measure: PLS-C 1200, 1600, 2000, 2400, 3000 The PLS-C model series designated as chemical palletizers correspond, with their capacities of 1200, 1600, 2000, 2400 and 3000 bags per hour, to filling capacities as they are characteristic for the chemical basic material industry, the plastics producing petrochemical facilities and the fertiliser industry. Sliding plates with regulated air pressure Typical for chemical...

Open the catalog to page 7

Palettieranlagen englisch, ohne Textfarbe:Layout 1 Filling, palletizing, packaging, loading. The entire process from a single source . . . PLS-B – The high-speed palletizers . . . Favourites of the building materials industry With throughput rates of 1200 up to maximum 3000, 4000 and 4500 bags per hour, depending on the layer pattern employed, the model range PLS-B palletizing machines fulfil the requirements of the building material producers. Tailored to the relatively rigidly-formed kraft paper valve bags used in these industries, the B-series Möllers palletizers are often equipped with...

Open the catalog to page 8

Palettieranlagen englisch, ohne Textfarbe:Layout 1 PLS-B 1200, PLS-B 2000 PLS-B 2400, PLS-B 3000 PLS-B 4500 PLS-B Universal from the B-series are equipped with spacer conveyors. The employment of an installed double lower layer feeder for gentle transfer of the bag layers onto the slide plate serves not only the safety of the large palletizer capacity but also the greatest possible care for the bags. Universal-type for limp bags Building materials and building additives, apart from being filled in firm valve bags, are also filled in less sturdy bags such as plastic valve bags or open bags....

Open the catalog to page 9

Palettieranlagen englisch, ohne Textfarbe:Layout 1 Filling, palletizing, packaging, loading. The entire process from a single source . . . Alternative in the medium segment: PGS, the universal fork palletizer For many packed goods, the fork palletizer is a sensible alternative to the slide plate palletizing machines Built for decades and valued by many operators as a machine with decades-long experience of high availability, the PGS palletizing machine, in its current version, corresponding to the latest state-of-the-art, offers an important alternative to the slide plate palletizers. The...

Open the catalog to page 10

Palettieranlagen englisch, ohne Textfarbe:Layout 1 Palletizing at sight height and alternating on several pallets PFS – Floor Module Palletizer and Multi-Palletizer Palletizing machines of the PFS model range, apart from the characteristic advantages of all Möllers palletizers offer two special characteristics:1.The low-level design. PFS machines are configured from stand-alone modules which perform the palletizing process close to floor-level and at a height offering a good overall view. 2. The variable capacity spectrum. With their typical throughput rates, the PFS palletizers make...

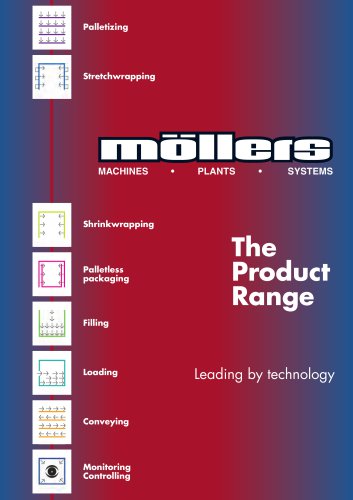

Open the catalog to page 11All Möllers catalogs and technical brochures

-

HSB-2600

4 Pages

-

2in1 Series_2022

13 Pages

-

HSA-Vario

16 Pages

-

Seminare

16 Pages

-

PLS-C

16 Pages

-

PSH-1 / PSH-2 / PSH-Vario

12 Pages

-

Automatic stretch hooder

16 Pages

-

Bag Loading Systems

11 Pages

-

Full Line. High Quality.

32 Pages

-

FIBC Filling Systems

6 Pages

-

Valve-Bag Filling Systems

8 Pages

-

Palletless Packaging Lines

16 Pages

-

R&D Center

9 Pages

Archived catalogs

-

2in1 Series_2011

13 Pages