Catalog excerpts

Machines, Plants, Systems for the Building Materials Industry

Open the catalog to page 1

Partner to the building materials industry Möllers is an excellent engineering partner Möllers and the building materials industry have a partnership that has proved its worth over decades. Conveying, storing, bagging, packaging and loading cement and other building materials, these are all operations where we have been providing engineering expertise to discerning customers for decades. We have built an outstanding reputation for Möllers throughout the world by planning and building reliable high-performance plant. Film-wrapped pallets for protection during transport Precise metering,...

Open the catalog to page 2

On call for clients, communication with the market Prompt service maintains the efficiency and availability of our clients' plants, and ensures longterm, cost-effective operation. Seminars, conferences and appearances at important trade fairs throughout the world keep us in contact Engineering expertise Plant and machinery Filling systems Palletless shrink wrapping systems Loading systems The Möllers control and display technology provides a dependable basis for monitoring complex process sequences, enabling precise intervention as necessary, rapid detection of the cause of any malfunction,...

Open the catalog to page 3

Packaging in the building materials production process: Engineering expertise is crucial Photo (installation): By kind permission of Dyckerhoff AG ̈ Product quality and delivery service are considered the prime competitive factors in the building materials industry. All production processes with their often numerous, increasingly highly automated and closely interlinked stages, have to accept and satisfy these market demands. Extremely high throughput rates, and sometimes a great variety of types and grades are other typical process parameters in building material plants that are subject to...

Open the catalog to page 4

Thinking about cement: Möllers is an excellent engineering partner ̈ Möllers is established worldwide as a competent specialist in plant engineering for packaging building materials. We think about cement; our knowledge and capability, our thinking and efforts are devoted largely to filling and bagging cement, other binders and dry mixes, aggregates, fillers and process materials, and fluid and pasty construction-chemistry products. Knowledge of the industry from over half a century’s experience We provide engineering with the benefit of over 55 years’ experience in the industry. Möllers...

Open the catalog to page 5

Conveying, storage, filling, distributing, packaging and loading: We are familiar with building materials ̈ The imperative of rationalisation has imposed far-reaching changes over recent decades on the filling, packaging and loading systems used in the building materials industry. Möllers has been a major contributor to this development. This has resulted in a product range extending from conveying bulk materials to various processes for handling bagged materials, including silo systems, bulk loading systems and bag filling systems. The breadth of the Möllers product range reflects the...

Open the catalog to page 6

Silo systems: Complete Möllers silo systems with bucket or pneumatic feed, and with aeration and extraction systems and integral filling facility Palletizing and securing pallet loads: Möllers automatic bag palletizing machines with output rates of up to 5,000 bags per hour. Möllers pallet shrink wrapping and transverse stretch hooder plant Palletless despatch units: Shrink-packaging plant using the Möllers reverse hood shrink system. Ruggedized packages – cost-effective and environment-frien

Open the catalog to page 7

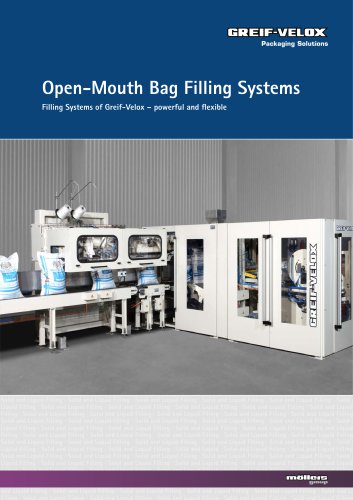

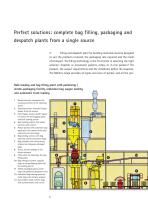

Perfect solutions: complete bag filling, packaging and despatch plants from a single source ̈ Filling and dispatch plant for building materials must be designed to suit the products involved, the packaging rate required and the mode of transport. The filling technology is the first factor in selecting the right solution: Impeller or pneumatic packers, rotary or in-line packers? The product, the output requirements and the conditions define the response. The Möllers range provides all types and sizes of packer, and all the per- Bulk loading and bag filling plant with palletizing /...

Open the catalog to page 8

Foreign body screen removes any large impurities from the material Möllers bucket elevators have repeatedly proved their worth for feeding storage silos and loading filling plant supply hoppers Horizontal feed gate for feeding the bag filling machine ipherals from foreign body screen through automatic bag applicators to valve sealing units and ancillary equipment such as checkweighers and bag checking stations. Which vehicles are to be loaded, what is the transport infrastructure like for product shipping, what degree of mechanisation is desired for loading? These questions must be answered...

Open the catalog to page 9

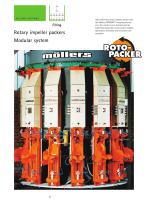

FILLING SYSTEMS Rotary impeller packers Modular system High-efficiency rotary impeller packer with the Möllers ROTRONIC® weighing electronics. The machines are characterized by high filling capacities and accurate weights, operational reliability and low power consumption

Open the catalog to page 10

Impeller roto-packer output with 50 and 25/35 kg bags, product CEM I 42.5 N 50 kg bags: 900 to 5,000 bags per hour 25 and 35 kg bags: 1,000 to 5,500 bags per hour 5 000 Typical filling module equipment ̈ Möllers rotary impeller packers are the best choice when it is a question of bagging cement and other very fine-grained products at medium to extremely high filling rates. They are built with 3 to 16 filling spouts and have horizontal impellers adapted to suit this specific type of product. The functional, modular method of construction makes it possible to produce cost-effective,...

Open the catalog to page 11

FILLING SYSTEMS Möllers Rotronic® packer control Coarse Flow · Vibration cut-out · Setpoint/ actual value comparison · Broken bag check · Coarse/fine flow changeover point Coarse Flow · Vibration cut-out · Setpoint/ actual value comparison · Run-on On-linecontrol · Selfoptimization · Optimization of the coarse/ fine changeover Point · Run-on correction On-linecontrol · Selfoptimization · Run-on correction Closed loop filling A high filling rate combined with consistent filling weight metering – this is principally the function of the electronic weighing system independently fitted to each...

Open the catalog to page 12All Möllers catalogs and technical brochures

-

HSB-2600

4 Pages

-

2in1 Series_2022

13 Pages

-

HSA-Vario

16 Pages

-

Seminare

16 Pages

-

PLS-C

16 Pages

-

PSH-1 / PSH-2 / PSH-Vario

12 Pages

-

Automatic stretch hooder

16 Pages

-

Bag Loading Systems

11 Pages

-

Full Line. High Quality.

32 Pages

-

FIBC Filling Systems

6 Pages

-

Valve-Bag Filling Systems

8 Pages

-

Palletizing Systems

16 Pages

-

Palletless Packaging Lines

16 Pages

-

R&D Center

9 Pages

Archived catalogs

-

2in1 Series_2011

13 Pages