Catalog excerpts

Rotary Impeller Packer Pneumatic Roto-Packer In-line Packing Machine Valve Bag Applicator

Open the catalog to page 1

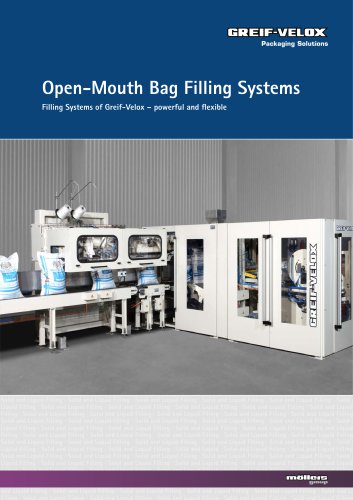

Automatic bag filling systems As one of the world’s leading suppliers of bag filling and packaging plant, Möllers produces valve bag filling machines with the most advanced engineering using almost all filling systems, configured as rotating packers, in-line packers and single packers, depending on the type of system. The Möllers range of bag filling machines is available with a wide variety of performance ratings, providing an efficient packaging solution for all materials. Electronic weighing systems are an integral component of Möllers packers, providing a high level of filling weight...

Open the catalog to page 2

Modular Impeller Roto-Packer Filling modules form the basic components The basic module of the Möllers impeller packer is the filling module. It combines the filling impeller with the filling spout, the bag holder and the weighing electronics as a complete bag-filling unit. The filling modules are mounted on a packer silo from which the material flows. The filling rate of a module is about 350 bags per hour for medium fineness cement. With a suitable number of filling modules on a packer silo, filling rates of 1,000 to 5,500 bags per hour are achieved. To make economic use of the high work...

Open the catalog to page 3

Möllers Rotronic® packer control Closed loop filling A high filling rate combined with consistent filling weight metering – this is principally the function of the electronic weighing system independently fitted to each filling module of a Möllers impeller packer. The electronic filling system controls the entire filling sequence, performing several functions directly affecting the precision of the filling process. The electronics constantly measures the flow characteristics of the product by the millisecond, matching the fine/coarse filling switch-over point to adjust the filling weight to...

Open the catalog to page 4

Efficient filling weight mean adjustment The sophisticated weighing electronics of the Möllers Rotronic® control unit fills the valve bags with a precision significantly above the calibration accuracy. However, separation loss is one of the unavoidable characteristics of the valve bag and its filling technology. It refers to the amount of product spilt from the valve when the bag is separated from the filling spout. It varies from bag to bag, it is compensated in the filling process by a set degree of product overfill. When variations outside the normal distribution The checkweigher...

Open the catalog to page 5

Pneumatic rotary and in-line packers The Möllers rotary packer with air filling system can be used for many bulk materials with poor flow properties and mixtures of coarse and fine particles or of particularly heavy and light components. Each filling module consists of a pressurized filling chamber with a cone-type closure valve, a level indicator, a pivoted filler pan bottom and the Möllers Rotronic® weighing system. pneumatic filling system are that blends to be filled do not separate, the elimination of mechanical strain on the product, low-dust filling due to low feed pressure, and the...

Open the catalog to page 6

Bag sealing before bag discharging The increasing demand for bag packs that can be handled without dirt requires hermetic sealing of the bag valves. The bag sealing system developed for this by Möllers seals the valves by ultrasound , to ensure clean handling along the supply chain. Each filling module is fitted with its own sealing unit. The sealing process comes immediately after the filling process and before the bag is discharged. The cleanly filled valve bag is removed from the filling spout, the valve is gripped by the sealing device and ultrasonically sealed. The bag is then...

Open the catalog to page 7

Impeller in-line packers Valve bag filling machines in in-line formation are made up with one to four filling spouts from the same filling modules as impeller Roto-Packers. The machines can be operated with manual bag feed and fully automatically with specially developed bag applicators. Their compact format provides great planning flexibility, with modest requirements in terms of building structure. Four-spout in-line packer in accordance with the Möllers module system Dedusting system Aeration cushion Impeller filling module Bag holder with vertical discharge 5 Weighing electronics Output...

Open the catalog to page 8

Automatic valve bag applicators Cassette magazines allow rapid changes between different types of bag The mode of operation of the Möllers valve bag applicators for rotating filling machines has been matched to the high bag filling rate of the Roto-Packer. Designed for a throughput of up to 4,500 bags per hour, it combines a high work rate with great precision – which is essential for intact application of the bags to the filling spouts passing in rapid succession in front of the bag applicator. The bag applicator can be fed with empty bags from various types of bag magazine. Cassette...

Open the catalog to page 9

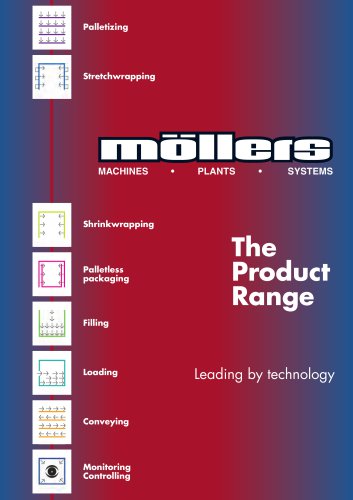

Exemplary packaging plants from a single source A Complete packaging systems Filled materials still have to be packed. An industrial packing process requires additional downstream operations to load and handle products efficiently and bring them to market quickly. Palletizing, pallet stretch and shrink wrapping and palletless stretch / shrink packaging using the extremely cost-effective Möllers reverse hood system are essential elements for efficient freight movement worldwide. Packaging plant for this comprehensive process capable of satisfying industrial demands in terms of integrability,...

Open the catalog to page 10

Producat® records the machine data at control level and prepares it for the data management level For highly automated palletizing and packaging plant to function smoothly, it must have an impeccable central control and monitoring system to reliably support the supervision functions with minimal manpower. The Producat® computer-based control and visual display program developed for this purpose by Mollers provides all the dialogue tools essential for operation, housed in a central terminal: 3. Diagnostic routines immediately and directly available if there is a fault, with optional link to...

Open the catalog to page 11All Möllers catalogs and technical brochures

-

HSB-2600

4 Pages

-

2in1 Series_2022

13 Pages

-

HSA-Vario

16 Pages

-

Seminare

16 Pages

-

PLS-C

16 Pages

-

PSH-1 / PSH-2 / PSH-Vario

12 Pages

-

Automatic stretch hooder

16 Pages

-

Bag Loading Systems

11 Pages

-

Full Line. High Quality.

32 Pages

-

FIBC Filling Systems

6 Pages

-

Valve-Bag Filling Systems

8 Pages

-

Palletizing Systems

16 Pages

-

Palletless Packaging Lines

16 Pages

-

R&D Center

9 Pages

Archived catalogs

-

2in1 Series_2011

13 Pages