Catalog excerpts

PURE. SUSTAINABLE. EFFECTIVE.

Open the catalog to page 1

VACUUM AND FILTER TROLLEY PAG E 1 0 EVAPORATORS WATER – A VALUABLE ASSET… Equipment for water recycling? Many business still think such systems are at most “nice-to-have.” yet the facts and figures and greater environmental awareness say something else: Nowadays, water recycling is an absolute “must have.” PAG E 2 0 ULTRAFILTRATION PAG E 3 6 A SOLUTION FOR EVERY PROBLEM PAG E 4 6 PRODUCTS AT A GLANCE PAG E 4 8 CONTACT PAG E 5 0 For info on our centrifuges and tramp oil separators, visit www.mkr-metzger.de or request the product brochures directly from us. Clean water is increasingly...

Open the catalog to page 2

MKR has developed into a worldwide operating company with more than 55 employees. 2015 Custom-fit: Four different evaporator systems for customised solutions Anderl and Thomas Metzger A SUCCESS STORY – TRADI TION BECOMES INNOVATION. A brilliant idea of the founder, Anderl Metzger, was the foundation stone: The MKR Metzger company can now look back on three successful decades, in which it developed from a one-man business into an internationally operating, innovative company. MANAGEMENT ANDERL AND THOMAS METZGER NUMBER OF EMPLOYEES OVER 55 (IN CONSULTING, DEVELOPMENT, DESIGN, SALES, SERVICE...

Open the catalog to page 3

FROM COMPETENT ADVICE THROUGH TO INTELLIGENT SOLUTION. We offer you a full service from A to Z. A D V I C E // SERVICE The MKR team has set itself the standard of providing competent customer advice under ecological and economical aspects. Depending on the initial situation, our customers’ priorities are economy, targeted problem solution and added value. L A B O R A T O R Y // DEVELOPMENT At the beginning there is an idea and the announced customer benefit. Fluids are analysed and documented in our own laboratory, so that we can then demonstrate the practicability of the idea in the MKR...

Open the catalog to page 4

UNBEATABLE ARGUMENTS – 6 REASONS FOR MKR. LOWER DISPOSAL COSTS MEAN HIGHER PROFI TS. With our MKR units you save costs, effort, time and energy. Our units enable high overall cost savings as well as a distinct productivity increase for your company. SAVE REPAIR COSTS MKR units enable top productivity for low energy consumption. You also save valuable working hours and relieve your employees’ workload. The simple and fast handling of the units also contribute to their effectiveness. Many of our customers are surprised by the durability of MKR units and the low repair costs. Furthermore we...

Open the catalog to page 5

VACUUM AND FILTER TROLLEYS VACUUM AND FILTER TROLLEYS 01 VACUUM AND FILTER TROLLEYS 01/1 THE CLEANING HOSE OPTION TECHNICAL DATA

Open the catalog to page 6

01/2 VACUUM AND FILTER TROLLEYS // THE ADVANTAGE S SAVE TIME AND COSTS FOR THE INDUSTRIAL SPRING CLEAN. VACUUM AND FILTER TROLLEYS VACUUM AND FILTER TROLLEYS 01/1 VACUUM AND FILTER TROLLEYS // THE PERFECT SOLUTION MAKE YOUR COMPANY MORE PRODUCTIVE. Fast and easy complete cleaning of all your machine tools Complete industrial cleaning was previously strenuous: With industrial vacuum cleaners, high-pressure cleaners, oil shovels, protective gloves and cloths were all used to get to grips with the dirt, some highly toxic, manually. Depending on the size of the operation, it can take hours of...

Open the catalog to page 7

VACUUM AND FILTER TROLLEYS VACUUM AND FILTER TROLLEYS 01/4 VACUUM AND FILTER TROLLEYS // APPLICATION & AREAS OF USE 01/6 VACUUM AND FILTER TROLLEYS // THE PROCE SS / DIAGRAM COMPLICATED? WRONG. Simply go to the machining plant and clean it in next to no time: That’s how easy it is with the mobile MKR units for complete cleaning. They can be used to extract, care and then return 500 litre of contaminated metalworking fluid to the production process in only 15 minutes, including cleaning the metalworking fluid tank. The high-performance MKR units type SF 250, SF 500, SF 700 and SF 1000...

Open the catalog to page 8

INTELLIGENTLY DESIGNED – 10 TECHNICAL HIGHLIGHTS. EASY OPERATION Easy and convenient operation of the three functions (extraction, high-pressure cleaning and draining). Our vacuum and filter trolleys are perfectly thought-through and are tailored to the needs of our customers. This guarantees effectiveness and time savings. HIGH-SUCTION VACUUM PUMP Efficient filter nonwoven with a particle rating of up to 60 µm. The integrated manual nonwoven reel ensures easy separation of the filter cake from the nonwoven. High-suction pump for extracting the process medium to be cleaned. At the same...

Open the catalog to page 9

VACUUM AND FILTER TROLLEYS THE TECHNOLOGY IN DETAIL. E-DRIVE OPTION E-DRIVE OPTION VACUUM AND FILTER TROLLEYS VACUUM AND FILTER TROLLEYS 01/8 VACUUM AND FILTER TROLLEYS // TECHNICAL DATA UNIT VALUE UNIT VALUE Main tank Swarf tray UNIT VALUE Swarf remover UNIT VALUE Swarf remover UNIT VALUE Main tank Swarf remover UNIT VALUE Main tank Main tank Swarf remover Clean tank Swarf remover Dimensions Main tank Main tank Suction head (stat.) mm WS Suction head (stat.) m WS m Suction head (stat.) m WS m Suction head (stat.) m WS m Suction head (stat.) m WS m Empty weight Suction capacity Empty weight...

Open the catalog to page 10

02/6 AREAS OF USE & PERFORMANCE CHARACTERISTICS

Open the catalog to page 11

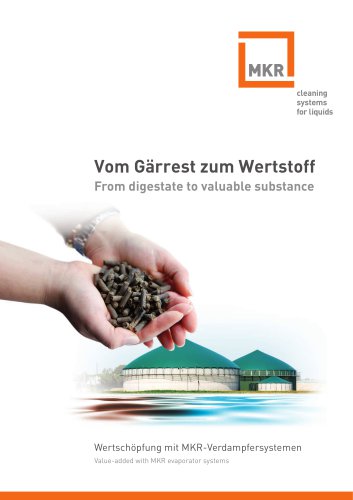

02/1 EVAPORATORS // THE PERFECT SOLUTION SAVE TIME, ENERGY AND UP TO 95% OF YOUR DISPOSAL COSTS. INCREASE THE EFFICIENCY OF YOUR PRODUCTION CYCLES. Effective wastewater treatment with the MKR evaporator technology Technically very well thought-through, intelligently designed and controlled, MKR evaporators (ET series) are now indispensable for production cycles with process media. Low energy consumption, maximum efficiency, lower material consumption (chemicals), top distillate quality, fast and easy maintenance and operability save you valuable time and money. You also relieve the workload...

Open the catalog to page 12

02/5 EVAPORATORS // THE PROCE SS / DIAGRAM HOW IS MORE EFFICIENCY MADE POSSIBLE? THROUGH MKR EVAPORATOR TECHNOLOGY. Mechanical vapour compression leads to continuous reuse of the energy contained in the steam. The evaporation heat exchanger of the evaporator with forced flow and consistent use of the heat from the distillate enable the low-energy consumption from 35 watt hours per litre. The compression control and integrated distillate aftertreatment by a coalescer product top distillate qualities. The evaporator operates fully automatically. The sensors monitor the process and prevent...

Open the catalog to page 13All MKR Metzger GmbH catalogs and technical brochures

-

UC 1

1 Pages

-

MKR Evaporator

8 Pages

-

Centrifuge OSD 500

2 Pages

-

Centrifuge OTC 350 VA

1 Pages

-

Centrifuge OTC 350

1 Pages

-

TM 450 UV

1 Pages

-

TB 250 VA

1 Pages

-

TB 250

1 Pages

-

SF 500

2 Pages

-

SF 250

1 Pages

-

MKR Cleaning Systems

20 Pages