Catalog excerpts

RV-SQ/RH-SQH Series Industrial Robots Supporting the Mitsubishi Electric INDUSTRIAL ROBOTS SUPPORTING THE MISTSUBISHI ELECTRIC List of SQ-series Models Supporting Classification Robot name System Configuration Hand curl tube Hand input cable Hand output cable (Optional) Air hand interface 2A-RZ365 (sink) / 2A-RZ375 (source) (Optional) Connection with peripheral devices Note 1) iQ Platform Programmable controller (*2) Connection cable between robot CPU and DU 2Q-RC-CBL Drive unit DU3-7x0 DU2-7x0 Solenoid valve set (Optional) Servo amplifier Vision sensor (Optional) Machine cable Personal computer cable (*2) Teaching pendant R32TB, R56TB (Optional) Personal computer *Must be prepared by the customer RT ToolBox 2 Robot total engineering support software (Optional) *1: The customer will select each sequencer unit. *2: For details, refer to the sequencer manuals. Note 1) Select an appropriate interface according to the I/Os or network function of the peripheral. HEAD OFFICE: TOKYO BUILDING, 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN Governmental export permits are required for the export of products used for strategic materials and service. This brochure has been issued in Feb. 2009. The contents of this brochure are subject to change for improvements without notice. Contact with Mitsubishi when referring to this brochure. RV-SQ/RH-SQH Series

Open the catalog to page 1

A New Concept Only Possible by Mitsubishi Electric. iQ Platform opens up the future of automation, by integrating, optimizing, and innovating the shop floor. An Evolution of the S Series. Functions 1 New teaching pendant (optional) Improved display performance and operability New enhanced teaching pendant (optional) No need to bring a PC to the site Enhanced teaching pendant [R56TB] Five times greater display performance (vs. R28TB) [VGA (640 x 480] touch panel] adopted You can use HMI tools equivalent to the RT tool box on the teaching pendant. Ergonomic design improves operability....

Open the catalog to page 2

A New Concept Only Possible by Mitsubishi Electric. iQ Platform opens up the future of automation, by integrating, optimizing, and innovating the shop floor. An Evolution of the S Series. Functions 1 New teaching pendant (optional) Improved display performance and operability New enhanced teaching pendant (optional) No need to bring a PC to the site Enhanced teaching pendant [R56TB] Five times greater display performance (vs. R28TB) [VGA (640 x 480] touch panel] adopted You can use HMI tools equivalent to the RT tool box on the teaching pendant. Ergonomic design improves operability....

Open the catalog to page 3

RV-SQ/RH-SQH Series Industrial Robots Supporting the Mitsubishi Electric INDUSTRIAL ROBOTS SUPPORTING THE MISTSUBISHI ELECTRIC List of SQ-series Models Supporting Classification Robot name System Configuration Hand curl tube Hand input cable Hand output cable (Optional) Air hand interface 2A-RZ365 (sink) / 2A-RZ375 (source) (Optional) Connection with peripheral devices Note 1) iQ Platform Programmable controller (*2) Connection cable between robot CPU and DU 2Q-RC-CBL Drive unit DU3-7x0 DU2-7x0 Solenoid valve set (Optional) Servo amplifier Vision sensor (Optional) Machine cable Personal...

Open the catalog to page 4All MITSUBISHI ELECTRIC AUTOMATION catalogs and technical brochures

-

FX-Family MELSEC PLC

104 Pages

-

MELFA Family

64 Pages

-

Compact PLC Family Catalogue

122 Pages

-

HMI-Family Visualisation Tools

90 Pages

-

The Automation Book

156 Pages

-

QS90SR2SP

4 Pages

-

Q/L-Family

114 Pages

-

ME96-NSR

32 Pages

-

ME96-SS Series

32 Pages

-

ECOWEBSERVER III

16 Pages

-

PRODUCT OVERVIEW

2 Pages

-

POWER & ENERGY PORTFOLIO

2 Pages

-

RV-2SD-SQ BROCHURE Ver. B

3 Pages

-

FX3S Brochure

6 Pages

-

GT14 Handy GOT Brochure

2 Pages

-

CNC DRIVES GENERAL CATALOG (V-M)

11 Pages

-

FX3GE Brochure

2 Pages

-

GT16 Handy Brochure

2 Pages

-

FX3U-ENET-ADP Brochure

4 Pages

-

ME96-SS Series Brochure

32 Pages

-

GT14 Brochure

3 Pages

-

F920GOT F930GOT Brochure

2 Pages

-

FX2NC-ENET-ADP Brochure

2 Pages

-

FX3U-1PG Brochure

2 Pages

-

LOW VOLTAGE SWITCHGEAR

12 Pages

-

Safety & Flexibility

16 Pages

-

MR-MQ100 Single Axis Motion

4 Pages

-

LD77MH Simple Motion Module

12 Pages

-

ST Series

4 Pages

-

GOT1000

13 Pages

-

F900

16 Pages

-

E1000

12 Pages

-

QE81-WH Energy Module

8 Pages

-

ME96-NSR Energy Meter

32 Pages

-

CC-Link

29 Pages

-

EnergyPAQ

2 Pages

-

M70 Series

8 Pages

-

C70 Series For iQ Platform

19 Pages

-

M700V Series

11 Pages

-

WS Series Circuit Breaker

192 Pages

-

WS-V Series

260 Pages

-

QS Safety PLC and CC-Link Safety

56 Pages

-

Q Series

31 Pages

-

MES Interface IT

7 Pages

-

Q Series Redundant System

31 Pages

-

iQ Sequence Controller

33 Pages

-

Inverter family

20 Pages

Archived catalogs

-

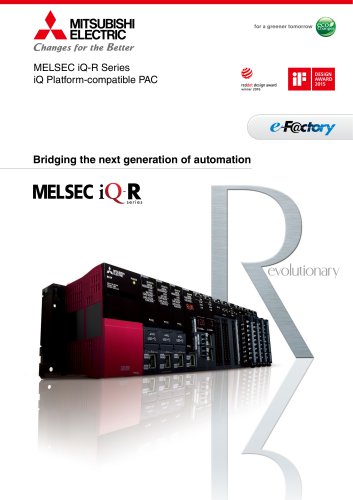

MELSEC iQ-R series/System Q/L series

152 Pages

-

FX3UC

4 Pages

-

L Series

4 Pages

-

COGNEX

2 Pages

-

Programmable Logic Controllers

28 Pages

-

MELFA Industrial Robots

50 Pages

-

Frequency Inverters

8 Pages

-

Global and open Field Network

12 Pages

-

Control Units

8 Pages

-

Melsec PLC

85 Pages