Catalog excerpts

Mitsubishi Programmable Controllers MELSEC PROCESS CONTROL / REDUNDANT SYSTEM

Open the catalog to page 1

MELSEC process control is a flexible, highly reliable platform with advanced functionality designed to cost-effectively meet the needs of a wide range of industries. INDEX Needs & Solutions 03 Application Examples 05 Lineup 11 MELSEC Process Control Products 15 Reduce costs Mitsubishi Electric automation products give users the flexibility to configure their systems according to their needs, unlike a distributed control system (DCS), which is developed by the vender from the initial design phase. This can greatly reduce initial and running costs. Implement sophisticated process control...

Open the catalog to page 2

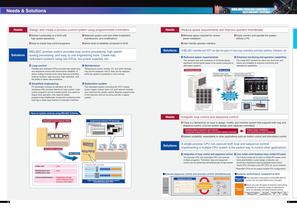

Design and create a process control system using programmable controllers. I Similar functionality to a DCS with high speed operations I Easy to create loop control programs I Reduced system cost (low initial investment, I Same level of reliability compared to DCS MELSEC process control provides loop control processing, high speed analog processing, and easy to use engineering tools. Create fully redundant systems using two CPUs, two power supplies, etc. Process and redundant CPUs provide high-speed loop and sequence control with phenomenal reliability. Q series analog modules have many...

Open the catalog to page 3

Application Examples Food processing Fine chemical manufacturing Applications previously requiring separate sequence and temperature control can now be controlled using a single process CPU. When a GOT is used in conjunction with the system, a space-saving, superior monitoring and control solution can be created. Mitsubishi Electric products help to provide integrated solutions for process automation and factory automation. Our process oriented products are well suited for manufacturing chemicals, such as medicines, paint, cosmetics, and detergent. Initial and running costs can be reduced...

Open the catalog to page 4

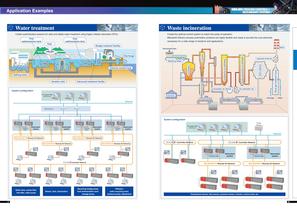

Application Examples Water treatment Waste incineration Create sophisticated systems for safe and stable water treatment using highly reliable redundant CPUs. Create the optimal control system to match the scale of operation. First sedimentation tank Mitsubishi Electric process automation products are highly flexible and ready to provide the core elements final sedimentation tank necessary for a wide range of solutions and applications. Park Sludge treatment facility Stack Settling basin Advanced treatment facility Melting furnace Aeration tank System configuration PC based HMI Fuel tank...

Open the catalog to page 5

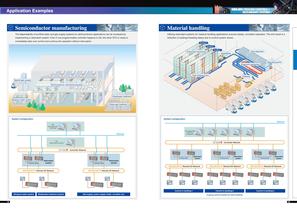

Application Examples Semiconductor manufacturing Material handling The dependability of purified water and gas supply systems for semiconductor applications can be increased by Utilizing redundant systems for material handling applications ensures steady, consistent operation. The end result is a implementing a redundant system. Even if one programmable controller happens to fail, the other CPU is ready to reduction in loading/unloading delays due to control system issues. immediately take over control and continue the operation without interruption. Building 3 Building 2 Building 1...

Open the catalog to page 6

Lineup Reduce costs by combining FA (Factory Automation) and PA (Process Automation) in the same platform. PC for monitoring and engineering PX Developer P.31 (Process control FBD software package) Design, debug, modify, and monitor FBD (Function Block Diagram) loop control programs. GX Developer MX Component P.39 GT SoftGOT1000 P.40 (ActiveX® (MELSEC programmable controller programming software) library for programmable controller communication) The primary programming, debugging, maintenance, and troubleshooting engineering tool for process and redundant CPUs. Allows user programs (on the...

Open the catalog to page 7

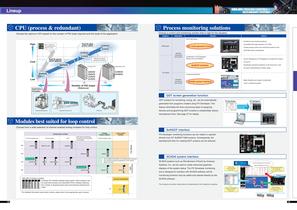

Lineup CPU (process & redundant) Process monitoring solutions Choose a control and monitoring solution that is right for the situation. Choose the optimum CPU based on the number of PID loops required and the scale of the application. Category Application Solution Feature GOT1000 Series · Excellent environmental resistance High Great for plant process control Other companies' loop controllers with program control Q25PRHCPU · Create process control and monitoring screens for the Q25PHCPU GOT1000 series automatically Q12PRHCPU General monitoring and control Q12PHCPU MELSEC-Q Series process...

Open the catalog to page 8

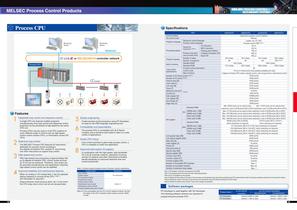

MELSEC Process Control Products CC-LfnklE or MELSECNET/H controller network Integrated loop control and sequence control_ • A single CPU can execute multiple programs simultaneously, thus loop control and sequence control programs can be processed at high-speed by the same • Process CPUs may be used in multi-CPU systems to cover different areas of control such as high-speed motion control (motion CPU), or information control (PC Extensive loop control_ • The MELSEC Process CPU features 52 instructions dedicated for process control including a two-degree-of-freedom PID, sample PI,...

Open the catalog to page 9

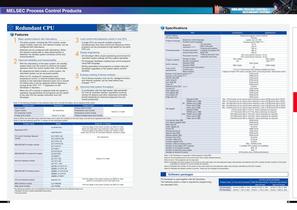

MELSEC Process Control Products Redundant CPU Redundant CPU, network, and power supply systems are provided to support various system configurations specific to application requirements. Redundant local I/O system Redundant remote I/O system The CPU directly accesses I/O modules. Ideal for systems requiring high-speed response. Monitoring Station Monitoring Station Monitoring Station or MELSECNET/H controller network Switching hub Ideal for distributed systems with multiple remote I/O stations. Monitoring Station Monitoring Station Switching hub Monitoring Station Monitoring Station or...

Open the catalog to page 10

"I Basic system/network with redundancy_ ' • The basic system, including the CPU module, power supply module, base unit, and network module, can be configured with redundancy. • Networks can be configured with redundancy. When the network module fails or cable disconnection is detected, the standby system continues control and Improved reliability and maintainability_ • With the redundancy of the basic system, the standby system takes over the control to continue the system operation when the control system fails. (Hot standby) • By replacing the failed module or entire system, the...

Open the catalog to page 11All MITSUBISHI ELECTRIC AUTOMATION catalogs and technical brochures

-

FX-Family MELSEC PLC

104 Pages

-

MELFA Family

64 Pages

-

Compact PLC Family Catalogue

122 Pages

-

HMI-Family Visualisation Tools

90 Pages

-

The Automation Book

156 Pages

-

QS90SR2SP

4 Pages

-

Q/L-Family

114 Pages

-

ME96-NSR

32 Pages

-

ME96-SS Series

32 Pages

-

ECOWEBSERVER III

16 Pages

-

PRODUCT OVERVIEW

2 Pages

-

POWER & ENERGY PORTFOLIO

2 Pages

-

RV-2SD-SQ BROCHURE Ver. B

3 Pages

-

FX3S Brochure

6 Pages

-

GT14 Handy GOT Brochure

2 Pages

-

CNC DRIVES GENERAL CATALOG (V-M)

11 Pages

-

FX3GE Brochure

2 Pages

-

GT16 Handy Brochure

2 Pages

-

FX3U-ENET-ADP Brochure

4 Pages

-

RV-SQ-RH-SQH BROCHURE Ver. B

4 Pages

-

ME96-SS Series Brochure

32 Pages

-

GT14 Brochure

3 Pages

-

F920GOT F930GOT Brochure

2 Pages

-

FX2NC-ENET-ADP Brochure

2 Pages

-

FX3U-1PG Brochure

2 Pages

-

LOW VOLTAGE SWITCHGEAR

12 Pages

-

Safety & Flexibility

16 Pages

-

MR-MQ100 Single Axis Motion

4 Pages

-

LD77MH Simple Motion Module

12 Pages

-

ST Series

4 Pages

-

GOT1000

13 Pages

-

F900

16 Pages

-

E1000

12 Pages

-

QE81-WH Energy Module

8 Pages

-

ME96-NSR Energy Meter

32 Pages

-

CC-Link

29 Pages

-

EnergyPAQ

2 Pages

-

M70 Series

8 Pages

-

C70 Series For iQ Platform

19 Pages

-

M700V Series

11 Pages

-

WS Series Circuit Breaker

192 Pages

-

WS-V Series

260 Pages

-

QS Safety PLC and CC-Link Safety

56 Pages

-

Q Series

31 Pages

-

MES Interface IT

7 Pages

-

iQ Sequence Controller

33 Pages

-

Inverter family

20 Pages

Archived catalogs

-

MELSEC iQ-R series/System Q/L series

152 Pages

-

FX3UC

4 Pages

-

L Series

4 Pages

-

COGNEX

2 Pages

-

Programmable Logic Controllers

28 Pages

-

MELFA Industrial Robots

50 Pages

-

Frequency Inverters

8 Pages

-

Global and open Field Network

12 Pages

-

Control Units

8 Pages

-

Melsec PLC

85 Pages