Catalog excerpts

2 Wire EDM in a new dimension The answer to future industrial standards 3

Open the catalog to page 2

highest precision Highest precision by innovative and highly reactive direct drive. Ultra fine surface by digitally controlled finishing. Best parallelism by user-friendly technology management. Optimum shape precision by intelligent automatic functions. Best energy efficiency ever by new energy saving modes. You need the last u in precision? You need surface qualities of 0.05 u Ra? The completely new developed, innovative and load-free Tubular Direct Drive communicates ultra-fast via optic fibres with the CNC and the high-speed amplifiers (Swift Optic Communication). As a result of this,...

Open the catalog to page 3

6 Swift Optic Communication Most innovative drive technology for most demanding applications. CNC control 1. System communication in real time 2. Highly dynamic reaction (shortest possible reaction time) New developed high speed servo amplifiers – 4 times faster! Tubular Direct Drive Convincing machine construction The extremely reactive response behaviour of the tubular direct drive needs an ultra-fast communication between CNC, servo amplifiers and drives itself (Swift Optic Communication). • The balanced construction and the ring-like force field of the tubular direct drive avoid...

Open the catalog to page 4

8 The Advance CNC control - the new standard in wire erosion The Advance control based on the Mitsubishi CNC M700 is captivating due to its user-friendliness and reliability. In spite of its complex range of functions, it can be operated intuitively via a control concept based on Windows XP. The logical menu structure and uncomplicated design allow you to quickly and reliably achieve your goal. You can run a 2D or 3D simulation of your program before or during the processing. The optimal generator setting creates the expert system E.S.P.E.R from your processing parameters. Evaluation,...

Open the catalog to page 5

:em. 3D data in Parasolid format and 2D data stored as DXF ge: quickly and easily move from set-up Loading the existing 3D data for your work piece in Parasolid format is easy as the Advance Control can process your original data in multiple formats. Using the integrated 3D CAM system, you can generate the eroding contours directly from your 3D Parasolid model and then transmit them to the built-in 2D CAM program. The 2D CAM generates the NC program from these specifications, which can also still be adjusted. Needless to say, you can also import 2D CAD data in DXF or IGES format directly...

Open the catalog to page 6

12 Optimised for best user-friendliness You do not want to loose time for the search of unnecessary mistakes? The electronic manual which is integrated in the CNC control helps you, e.g. by time meter and pictures, to organise necessary services in advance. In case of occurring alarm messages, they are analysed and the items to be checked are displayed. Photos and graphics help you to localise the maintenance points. You expect an optimum access to the working area? The automated vertical sliding door as well as the 3-sides lift tank ensure optimum access without using additional space....

Open the catalog to page 7

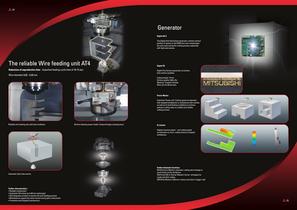

14 Generator Digital AE II The Digital Anti-Electrolysis generator controls vertical position of sparks on the EDM wire and compensates the wire wear during the cutting process, especially with high work pieces. The reliable Wire feeding unit AT4 Reduction of unproductive time - Superfast feeding cycle time of 10-15 sec. Digital FS Digital Fine Surface generator to achieve best surface qualities. Wire diameter 0,05 - 0,30 mm Cutting height: 10 mm Surface quality: 0,05 µ Ra Material: Tungslen Carbide Wire: 0,2 mm Brass wire Power Master Automatic Power and Cutting speed acceleration with...

Open the catalog to page 8

16 Lateral view Front view Working Table Footprint All indications in mm The dimensions may vary according to equipment. Modell Travel Path X Y Z Travel Path U V Max.Taper Angle Work piece dimensions X Y Z Work piece weight Wire diameter Max. power consumption Total weight Min. door opening mm mm mm kg mm kVA kg mm 400 x 300 x 220 ± 60 x ± 60 15° / 200 mm 810 x 700 x 215 500 0,05 - 0,30 13,5 3.060 1.700 x 1.965 17

Open the catalog to page 9

Lateral view Front view Working Table The dimensions may vary according to equipment.

Open the catalog to page 10

Official technology and application partner of Mitsubishi Electric DIN EN ISO 9001:2000 Certificate: 09 100 4371 MITSUBISHI ELECTRIC EUROPE B.V. • German Branch • FA-Mechatronics EDM Gothaer Str. 8 • 40880 Ratingen • Phone +49 - (0)2102 - 486 - 6120 • Fax +49 - (0)2102 - 486 - 7090 edm.sales@meg.mee.com • www.mitsubishi-edm.de Technical changes reserved. E 06.09 - 225 088

Open the catalog to page 11All Mitsubishi EDM catalogs and technical brochures

-

MV-R CONNECT

32 Pages

-

SG-R SERIES

29 Pages

-

MX600

19 Pages

-

MP CONNECT

32 Pages

-

mvs

48 Pages

-

mvr

23 Pages

-

EA8-S

2 Pages

-

EA-V Advance catalogue

17 Pages

-

FA-S Advance Series

20 Pages

-

MV-S

15 Pages

-

MV-R

17 Pages

-

ImageBrochure

11 Pages

-

BA

10 Pages

-

MV-Series

2 Pages

-

FD20 catalogue

2 Pages

-

ED24 catalogue

2 Pages

-

EA-series catalogue

2 Pages

-

BA Series catalogue

10 Pages

-

product overview

2 Pages

Archived catalogs

-

FA-S Advance

21 Pages

-

FA-S Advance Dutch

21 Pages

-

BA8

8 Pages

-

EA

2 Pages

-

EA 12V

11 Pages

-

PA20

8 Pages