Catalog excerpts

Wire-cut EDM – Ready for Production

Open the catalog to page 1

36 model series since 1964. Mitsubishi Electric. . . . . . . . . . . . . . . . . . . . . 5 Highlights . . . . . . . . . . . . . . . . . . . . . . . . . . 7 . . Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Tubular Shaft Motor. . . . . . . . . . . . . . . . . . . 11 Generator technology . . . . . . . . . . . . . . . . . 13 Precise Finish Circuit. . . . . . . . . . . . . . . . . . 15 Wire threading. . . . . . . . . . . . . . . . . . . . . . . 17 Simple operation. . . . . . . . . . . . . . . . . . . . . 19 Intelligent user guidance . . . . . . . . . . . . . . . 21 Remote...

Open the catalog to page 3

patent applications per year produced wire-cut EDM machines

Open the catalog to page 4

If you’ve got grand designs, you need someone strong you can count on. Since 1970, a growing throng of European companies have therefore been t urning to high-performance EDM machines from world market leader Mitsubishi Electric. Only by producing components in-house is it possible to tailor them perfectly to the intended task. Mitsubishi Electric resorts to its own controls, semicon ductors, motors and other items, which are adapted in detail to all requirements. The only thing you notice is that it works – and often for many decades after purchase. If you want to invest soundly in a...

Open the catalog to page 5

ODS OPTICAL DRIVE SYSTEM The speed of light ... ... for communication by fibre optics. The Tubular direct drives with their highly responsive control on the main axes fully exploit the benefits of high communication speed. No heat, no maintenance and no contact – just extra precision for good. At Mitsubishi Electric, this is known as “Changes for the Better”. Continued on page 11 PFC PRECISE FINISH CIRCUIT Extra precision and speed thanks to the generator that not only thinks, but also thinks ahead. If you want to achieve better results with fewer recuts, you need the right blend of...

Open the catalog to page 6

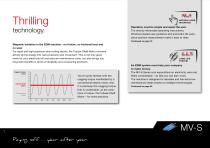

NATURAL USER INTERFACE Operation must be simple and assist the user. The directly retrievable operating instructions, Windows-based user guidance and automatic 3D workpiece position measurement make it easy to relax. Magnetic levitation in the EDM machine – no friction, no frictional heat and no wear For rapid and high-precision wire-cutting results, the Tubular Shaft Motor converts almost all the energy into nano-precision axis movement. This is not only good news for your electricity bill and reduces maintenance costs, but also brings you long-term benefits in terms of durability and...

Open the catalog to page 7

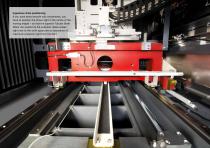

Ingenious drive positioning If you want extra-smooth axis movements, you have to position the drives right in the centre of the moving weight – so that the superior Tubular Shaft Motor can exploit its full potential. Glass scales right next to the work space are an assurance of maximum precision right from the start.

Open the catalog to page 8

Tons of solidity cast in steel. Solid machine body The specially selected Meehanite casting ensures durability that can be measured in decades and copes with high workpiece weights day after day. The rugged machine bed takes even the severest punishment in its stride – unlike many a less expensive material. Ergonomics in the work space The three-sided work table is ergonomically built on the Z = 0 level. This way workpieces can be perfectly positioned, even without clamping elements. Highgrade stainless steel components and the stainless steel tank ensure dependability and maintenance...

Open the catalog to page 9

The Tubular Shaft Motor converts energy directly into motion, without contact, without maintenance and above all without loss of precision – long-term. Combined with the 400 % faster fibre-optic- ased b control, this superior technology can truly show what it is capable of. The 12-year genuine manufacturer warranty on positioning accuracy is a guarantee of top-level durability. Your company’s technological edge has a name: Tubular Shaft Motor – from world market leader Mitsubishi Electric. Find out more about it here: www.mitsubishi-edm.de/tsm

Open the catalog to page 10

ODS OPTICAL DRIVE SYSTEM on positioning accuracy. Perfect drive What was it about the main X and Y axes of conventional drive systems that bothered developers at Mitsubishi Electric? The need for lubrication, the friction and frictional heat, power consumption, backlash, the cogging moment and above all the possible wear. Only a non-contact drive overcomes these drawbacks from the outset and is thus an assurance of better results and enhanced dependability over decades. Full speed of light The Mitsubishi Electric polymer optical fibres have decisive advantages – not only over conventional...

Open the catalog to page 11

Better tness straigh

Open the catalog to page 12

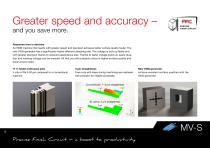

PFC PRECISE FINISH CIRCUIT Getting a grip on radii and corners On small inner and outer corners and complicated geometries, Corner Master 3 comes to your aid. You merely define your priorities, and optimisation is performed accordingly. Comparison of corner accuracies Conventional corner control Examples of Power Master machining applications Examples of workpieces Inner corner 60° (R: 0.2 mm) Stepped workpiece Stepped workpiece Workpiece with cross bores and cavities Better straightness and shape accuracy With precise control of the electrical discharge position, material is only removed...

Open the catalog to page 13

Twice-as-fast spark detection The high-speed digital control works up to twice as fast as traditional machines. This prevents wire breakage and increases machining speed noticeably at the same time.

Open the catalog to page 14

Greater speed and accuracy – and you save more. PFC PRECISE FINISH CIRCUIT Response time is decisive An EDM machine that reacts with greater speed and precision achieves better surface quality faster. The new V350 generator has a significantly higher effective sampling rate. The voltage is built up faster and with greater precision thanks to reduced capacitance loss. Thanks to faster voltage build-up, spark duration and working voltage can be lowered. All that you will probably notice is higher surface quality and lower power costs. 17 % faster multi-pass jobs 4 cuts of Ra 0.30 µm compared...

Open the catalog to page 15All Mitsubishi EDM catalogs and technical brochures

-

MV-R CONNECT

32 Pages

-

SG-R SERIES

29 Pages

-

MX600

19 Pages

-

MP CONNECT

32 Pages

-

mvr

23 Pages

-

EA8-S

2 Pages

-

EA-V Advance catalogue

17 Pages

-

FA-S Advance Series

20 Pages

-

MV-S

15 Pages

-

MV-R

17 Pages

-

ImageBrochure

11 Pages

-

BA

10 Pages

-

MV-Series

2 Pages

-

FD20 catalogue

2 Pages

-

ED24 catalogue

2 Pages

-

EA-series catalogue

2 Pages

-

BA Series catalogue

10 Pages

-

NA Essence catalogue

11 Pages

-

product overview

2 Pages

Archived catalogs

-

FA-S Advance

21 Pages

-

FA-S Advance Dutch

21 Pages

-

BA8

8 Pages

-

EA

2 Pages

-

EA 12V

11 Pages

-

PA20

8 Pages