Catalog excerpts

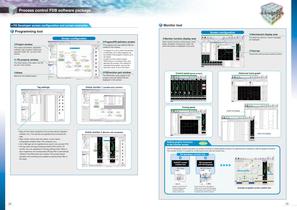

Ңހ Process instructions for advanced loop control such as two degree of freedom PID, sample PI and auto-tuning instructions. ➁ High-speed PID operation realizing an increase in the number of control loops. ■ Design of a system with outstanding cost performance is realized, providing an alternative to a conventional DCS system. > With included features such as, channel isolation, high accuracy, high resolution, range of alarm and input signal detection functions, the scope of application processes are increased. > Increased loop scale ➀ Loop control programs can be created easily by pasting...

Open the catalog to page 2

MELSEC Process Control Design a process control system using DCS with PLCs. (The PLC requires sufficient loop control and analog processes for the process application.) Օ Easily design modify and maintain a system containing both loop control and sequence control.Conventional process control systems were designed using separate controllers for loop control and sequence control. Easily create loop control programs. > ՕSoftware for each controller is different.Program for data transmission between controllers is complicated. Design, modify, and maintenance of programs was time consuming. Օ...

Open the catalog to page 3

MELSEC Process Control Personal computer for monitoring and engineering (FBD software package for process control) > Personal computer for engineering Process CPU (MELSEC PLC Programming software) > RS-232/USB Analog module Analog module I/O module Process CPU > MELSECNET/H, Ethernet (10/100Mbps) ՕRemote I/O module Process CPU Display device ՕRemote master station Channel isolated/non-isolated analog module ՕI/O module > MELSECNET/H remote I/O network Loop control ՕSequence control Remote I/O module > ՕRemote I/O module Channel isolated/non-isolatedanalog moduleՕI/O module >

Open the catalog to page 4

MELSEC Process Control > Same as programming toolPC/AT compatible personal computer running Windows NT4.0 or 2000. Display resolution 800 x 600 or higher.Օ Number of process CPU modules under monitor: Maximum 8 CPU modules (up to eight process CPU modules under monitor from one personal computer.) Number of monitor tags : Maximum 3,840Specifications ItemA faceplate modeling on process regulator is displayed to monitor and adjust (change the operation mode, SV/MV values, etc.) the loop control tags and digital tags. The pop-up tuning screen can be opened from this screen. Օ 8...

Open the catalog to page 9

MELSEC Process Control The latest two alarms or event messages are displayed. > Each monitor function (control panel, trend graph, faceplate, tuning panel, alarm list, event list screen) is displayed in this area. The PX Developer monitor tool does not contain functions to create graphic screens. An optional tool is required to add the graphic functions. The monitor function is created by combining this tool with the monitor tool. > The programs and user defined FBs are created in this window. The project parameters, applicable modules, tags, program names and execution cycle, etc., are set...

Open the catalog to page 10All MITSUBISHI Automation catalogs and technical brochures

-

MELSEC iQ-R Series

120 Pages

-

MR-FAMILY

117 Pages

-

FR-A741

4 Pages

Archived catalogs

-

MELSEC iQ-R series/System Q/L series

166 Pages

-

MR-J4

4 Pages

-

Q/L-Family MELSEC Modular PLC

114 Pages

-

MR-J3-BSafety

4 Pages

-

FX3UC

4 Pages

-

HMI E1000

4 Pages

-

ST series

4 Pages

-

SPAC

2 Pages

-

SUPER AE-SW

4 Pages

-

Material Handling

28 Pages

-

203684

52 Pages

-

Data 2009

8 Pages

-

Data Redundant System Q Series

27 Pages

-

219952

28 Pages

-

Data CC-Link/LT Safety

136 Pages

-

LVS Family

116 Pages

-

MR Family

90 Pages

-

HMI Family

58 Pages

-

MELSEC STlite

4 Pages

-

MELSEC System Q

84 Pages

-

L series

4 Pages

-

FX Family

90 Pages

-

Micro controller ALPHA 2

4 Pages

-

Mitsubishi Magasine

20 Pages

-

the automation book

188 Pages

-

Automotive

20 Pages