Website:

Mitee Bite

Website:

Mitee Bite

Catalog excerpts

Workholding Specialists Manual Actu CAD FILES Available Online: MITEEBITE.COM

Open the catalog to page 1

Mission Statement Our goal is to serve our customers by providing a complete range of the best low profile clamps, of the highest quality at competitive prices and delivered on time. This promise is backed and supported by our knowledgeable technical and sales staff who are available to assist our distributors and customers. Company Profile Mitee-Bite Products LLC was founded in 1986 and is located in a rural setting in the lakes and mountain region of New Hampshire. We are the innovator of compact, low-profile edge clamps, which improve production in CNC machining centers. Our original cam...

Open the catalog to page 2

Table of Contents Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clamp Type . . . . . . . . . . . . . . . . Category . . . . . . . . . . . . . Page Fixture Clamps. . . . . . . . . . . . . . . . . . . . . . . . . . . Cam Action. . . . . . . . . . . . . . . . . Fixtures. . . . . . . . . . . . . . . . 4 Knife Edge Clamps. . . . . . . . . . . . . . . . . . . . . . . . Cam Action . . . . . . . . . . . . . . . . Fixtures. . . . . . . . . . . . . . . . 4 . Series-9 Clamps. . . . . . . . . . . . . . . . . . . . . . . . . . Cam Action. . . . . . . . . . . . . . . . . Fixtures....

Open the catalog to page 3

Original Fixture Clamps The cam action MITEE-BITE Fixture Clamp is made up of two simple components: a hardened steel socket cap screw with an offset head and a brass hexagonal washer. > Low-profile makes computer programming easier > Cam action provides fast, strong clamping > Small size allows more parts per load > Simple design keeps cost low NOTE: Clockwise rotation is recommended. Locating pin should be on the right of workpiece. Part Torque Holding Clamps Number A B C D E F G* (Ft/Lbs) Force Per Pack STAINLESS STEEL Knife Edge Clamps Knife Edge Clamps can be used instead of the...

Open the catalog to page 4

Series-9 Clamps This adjustable low profile, cam action clamp provides clamping of different size workpieces merely by rotating the clamp to one of its other edges. The clamps are .394 (10mm) high and use a 1/2-13 (M12) cam screw. Each of the six clamping surfaces is a different distance from the centerline by .0394 (1mm) as shown in the chart. Therefore, one Series-9 Clamp can hold parts that vary up to .240 (9.4mm) simply by rotating the clamp to a different clamping surface. ® Serrated or smooth edges ® Heat treated and plated ® 4,000 lbs. (17800 N.m.) holding force TORQUE VALUES AND...

Open the catalog to page 5

Uniforce® Clamps The compact, economical MITEE-BITE Uniforce® Clamp enables you to fixture more parts on the machine table. The specially designed steel wedge spreads the clamping force uniformly on both sides of the 7075-T6 aluminum channel. ® Increases production ® Minimizes tool changes ® Holds two parts with equilateral clamping action ® Ideal for clamping flat or round workpieces ® Reduces wasted space ® See Locating Rails on page 28 ® Easily mated to hydraulic pull cylinders ® Ideal for pallet changers Thread Size Maximum Spread Number of Clamps Per Pack D* - A milled slot wider than...

Open the catalog to page 6

Machinable Uniforce® Clamps The compact MITEE-BITE Uniforce® clamp is available with extra material on the clamping jaws so it can be machined to conform to the shape of your workpiece enabling you to fixture unusual applications easily. The specially designed steel wedge spreads the clamping force uniformly on both sides of the 7075-T6 aluminum channel. The locking plate properly expands the clamp, while making it rigid for machining. Machine to a slip fit of workpiece. Clamp retracts after removing locking plate to make it easy to load parts. Note: Locking plate is used only to machine...

Open the catalog to page 7

OK-VISE® Clamps THREE-DIMENSIONAL MACHINING Due to a low-profile design of OK-VISE® Clamps, it is possible to execute flexible three-directional machining of workpieces with one fastening. This ability to machine a workpiece in three planes means improved accuracy. PULL DOWN ACTION The single wedge clamps keep the workpieces steadily in place, not allowing upward or downward movement. The double-wedge clamps generate a pull-down action pressing the workpieces towards the fixture base. MACHINABLE JAWS Single-wedge clamps are also available with extended jaws that can be machined to suit the...

Open the catalog to page 8

OK-VISE® Clamps SINGLE-WEDGE OK-VISE® CLAMPS Strong lateral clamping with a single wedge design. Part Number Mounting Screw (included) Pressing Force of Jaws (Lbs) 2,000 5,500 5,500 14,500 24,900 *47100 and 47110 have smooth jaws. DOUBLE-WEDGE OK-VISE® Increased clamping force and the double wedge design pulls the workpiece down. Part Number Mounting Screw (included) Max. Pressing Hardness Torque Force of of Jaws (Ft/Lbs) Jaws (Lbs) HRC MACHINABLE SINGLE-WEDGE OK-VISE® CLAMPS Additional material is added to these machinable jaws. Part Number Pressing Force of Jaws (Lbs) SPECIAL MODEL...

Open the catalog to page 9

Pitbull® Clamps The revolutionary Pitbull® Clamp remains the lowest profile, highest holding force clamp in the industry today. High vertical and horizontal clamping forces are generated, considering the size of the Pitbull® Clamps. It uses a standard cap screw and an oil resistant O-ring. The Pitbull® Clamp is available in 5 sizes and several styles, a tool steel knife edge for aggressive stock removal, a tool steel blunt edge for general purpose and a brass version to help prevent marring the workpiece. See Locating Rails on page 28. Unique features of Pitbull ® Clamps: ® Extremely low...

Open the catalog to page 10

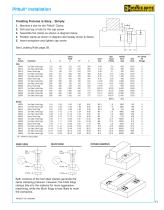

Pitbull® Installation Creating Fixtures is Easy... Simply: 1. 2. 3. 4. 5. Machine a slot for the Pitbull® Clamp Drill and tap a hole for the cap screw Assemble the clamp as shown in diagram below Position clamp as shown in diagram and loosely screw to fixture Insert workpiece and tighten cap screw Tool Steel, Knife Edge Tool Steel, Blunt Edge Brass, Blunt Edge Tool Steel, Knife Edge Tool Steel, Blunt Edge Brass, Blunt Edge Tool Steel, Knife Edge Tool Steel, Blunt Edge Brass, Blunt Edge Tool Steel, Knife Edge Tool Steel, Blunt Edge Tool Steel, Knife Edge Tool Steel, Blunt Edge Screw Size...

Open the catalog to page 11All Mitee Bite catalogs and technical brochures

-

Modular XYZ Xpansion® Pins

2 Pages

-

Loc-Jaw® Instructions

1 Pages

-

Fixturing for the Future

1 Pages

-

CATALOG 2017

52 Pages