Catalog excerpts

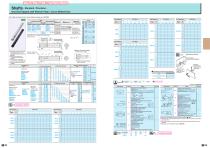

I For Pricing and Days to Ship,Please Configure Online) Shafts - Standard / Precision - One End Tapped with Wrench Flats / Cross-Drilled Hole (J)For Shafts w/o Wrench Flats or Cross-Drilled Hole, please see Bf3 R103 Annealing may lower hardness at wrench flats, cross-drilled hole and shaft end machined areas (effective thread length + approx. 10mm) Cross-drilled hole areas may be out of (^Circularity, Straightness, Perpendicularity Concentricity, Changes in Hardness B^" R97 (^Features of Low Temp. Black Chrome Plafnc ■ Shafts with Cross- work space. Bg | Part Numbed - fH - I^MMsql - [sc] - pT| - (LKC.etc.) ftfl [Configure Online] Alteration to L Dimension Tolerance [Application NotesI Applicable when L=200 or less for precision type. L dimensions can be specified in 0.1 mm increment for LKC. Set Screw Flat at One Location [ApplicationNotes| &Not applicable to precision shafts <8>Not available in combination with WFC. Set Screw Flats at Two Locations [ApplicationNotosl igjNot applicable to precision shafts. Orientation between set screw flats is random Not available in combination with FC. Second Set of Wrench Flats [Application NotoslOnly applicable to Shafts with Wrench Flats. Orientation between set screw flats is random. Change to Fine Tapped Thread [Application Notosl Applicable to D=12 or more 90-deg. Set Screw Flat at One Location | Application Notesl Only applicable to D=10 ~ 30. Not applicable to precision shafts. Not available in combination with WFiC 90-deg. Set Screw Flats at Two Locations [Application Hotes~| Only applicable to D=10 ~ 30. Not applicable to precision shafts. Not available in combination with FiC. Orientation between set screw Shaft Alteration [Application Notesl Only applicable to D=1 2,16,20,25 and 30. <8>Not applicable to precision shafts. Please see Shaft Alteration Overview for details if provided. EF R99 (J)When selecting multiple alteration additions, the distance between machined areas should be (J)The distance between wrench flats and cross-drilled holes should be greater than 2mm for Alterations may lower hardness. Please see EF R98

Open the catalog to page 1All Misumi America catalogs and technical brochures

-

ELECTRICAL & WIRING COMPONENTS

1992 Pages

-

Thrust Ball Bearings

1 Pages

-

Pan/Socket Head Cap Screws

1 Pages

-

Guides V-Shaped / Plate

1 Pages

-

Stopper Blocks

1 Pages

-

Stop Pins

1 Pages

-

Shafts Set Screw Grooved

1 Pages

-

Shafts Solid Type

1 Pages

-

High Precision Linear Shafts

1 Pages

-

Precision Linear Shafts

1 Pages

-

SHOT COUNTERS FOR MOLD

1 Pages

-

Lead Time Specials

12 Pages

-

Stainless Steel Products

8 Pages

-

Oil Free Bushings

1 Pages

-

Ball Splines

1 Pages

-

Shaft Collars -Wedge-

1 Pages

-

Shaft Collars -Slit-

1 Pages

-

Lead Screws

1 Pages

-

Linear Bushings

1 Pages

-

Shaft Collars

1 Pages

-

Shaft Supports

1 Pages

-

Dritti

1 Pages

Archived catalogs

-

Shafts -Both Ends Tapped-

1 Pages