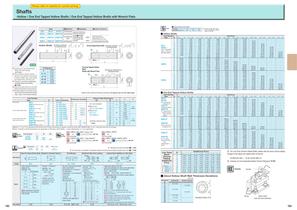

Shafts -Both Ends Tapped Hollow Shafts / Both Ends Tapped Hollow Shafts with Wrench Flats / One End Threaded Hollow Shafts / One End Threaded Hollow Shafts with Wrench Flats-

1Pages

Catalog excerpts

Please refer to website for current pricing. -Hollow / One End Tapped Hollow Shafts / One End Tapped Hollow Shafts with Wrench Flats- Black Chrome Plating ®Low temperature black chrome plating is not applied to the inside of hollow shafts, taps, bored holes and lateral holes, and may rust. (*) Changes in circularity, straightness. Circularity and outer diameter tolerance may not meet precision Annealing required for machining wrench flats and shaft end threading (effective thread length + approx. 10mm) may lower hardness. HollOW Shafts No Surface Treatment , u/ 0.4/ One End Tapped HollOW Shafts No Surface Treatment Shafts With Wrench flats machined areas ®About hollow shaft wall thickness deviations.EST please see on the right page ®When T1, T2 or T3 is selected as M, British Pipe CJ)Only "marked D and M dimensions are applicabl Thread mach ning is applied. (Ordering Code: MT1)®When Mx2.5+4: Steel Shafts. L and d dimensions in () are applicable. PSPJ / PSPJT / SPJ / SPJT ** Dia. 6 - 30 ** L, tap pilot hole may go through. PSPJ / PSPJT / SPJ / SPJT RSPJ/RSPJT /RSPTR SSPJ / SSPJT / SSPTR / PSPTR j^j |Part Number|" LT] " [K\ ' I sc I" (KKC.etc.) ® Alterations may lower hardness.R= R104 (*) For more than one alteration, the distance between machined areas should be greater than 2mm. EST P. 106 Revise P.P. Tolerance (Precision Grade) Alteration to L Dimension Tolerance Add Wrench Flats at Two Locations Lateral Hole Addition to One Side Outer diameter tolerance is Changes "LTolerance". One end or both ends are bored. (Used as pilot holes) Hole diameter VH7 is shown in Steel and Low Temp Chrome Plated Shafts. Two wrench flats will not be positioned in a coplanar relationship. Lateral hole added to one side. Lateral hole diameters are shown in the table below. I Ordering Code | One End RH5 Both Ends RH5-LH ®Two cross-drilled holes will not be oriented in a coplanar relationship. Hollow Shafts. One End Tapped Hollow Shafts Values in ( ) are for Stainless Steel Shafts. (J)The hollow I.D. "d" may vary due to the wall thickness deviations. (J)Not applicable to tapped end of "One End Tapped" type. SBurrs might remain inside after alteration. Hole positions are arbitrarily arranged with respect to other alterations. (3>Not applicable if interfering with other alterations. ■Volume Discount Rate For larger quantity orders "Days to Ship" may differ from publishec Hart Number | One End Tapped Hollow Shafts (J) For Low Temp Chrome Plated Shafts, please add low temp chrome plating charges to the above non-plated shaft unit prices. (J) Features of Low Temperature Black Chrome PlatingES" R118 | About Hollow Shaft Wall Thickness Deviations Deviation Value=A- Hollow Shaft (with side hole alteration]

Open the catalog to page 1All Misumi America catalogs and technical brochures

-

ELECTRICAL & WIRING COMPONENTS

1992 Pages

-

Thrust Ball Bearings

1 Pages

-

Pan/Socket Head Cap Screws

1 Pages

-

Guides V-Shaped / Plate

1 Pages

-

Stopper Blocks

1 Pages

-

Stop Pins

1 Pages

-

Shafts Set Screw Grooved

1 Pages

-

Shafts Solid Type

1 Pages

-

High Precision Linear Shafts

1 Pages

-

Precision Linear Shafts

1 Pages

-

SHOT COUNTERS FOR MOLD

1 Pages

-

Lead Time Specials

12 Pages

-

Stainless Steel Products

8 Pages

-

Oil Free Bushings

1 Pages

-

Ball Splines

1 Pages

-

Shaft Collars -Wedge-

1 Pages

-

Shaft Collars -Slit-

1 Pages

-

Lead Screws

1 Pages

-

Linear Bushings

1 Pages

-

Shaft Collars

1 Pages

-

Shaft Supports

1 Pages

-

Dritti

1 Pages

Archived catalogs

-

Shafts -Both Ends Tapped-

1 Pages