Website:

Magnetrol - AMETEK

Website:

Magnetrol - AMETEK

Group: AMETEK

Catalog excerpts

Side Mounting Liquid Level Switches DESCRIPTION Magnetrol® side mounting controls mount horizontally to any tank or vessel through a threaded or flanged pipe connection. Standard models are normally equipped with a single switch mechanism for high or low level alarm or control applications. Tandem models, with two switch mechanisms, are available for two-stage applications. FEATURES • Body material of cast iron, carbon steel or stainless steel • 300 series stainless steel float and trim • Threaded or flanged mounting • Specific gravity ratings down to 0.50 • Process temperatures to +1000° F (+538° C) • Choice of float size: • 21⁄2" (64 mm) • 21⁄2" × 4" (64 × 102 mm) • • • • Fuel tanks • Day tanks • Field-adjustable level differential • Flash tanks • Choice of switch mechanism: Dry contact Hermetically sealed Pneumatic • Choice of switch mechanism enclosure: NEMA 1 carbon steel for pneumatic TYPE 4X/7/9, Class I, Div. 1, Group C & D, polymer coated aluminum TYPE 4X/7/9, Class I, Div. 1, Group B, polymer coated aluminum • Scrubbers • Cooling towers • Dump valve controls • Condensate receivers • Boilers • Deaerators • Holding tanks

Open the catalog to page 1

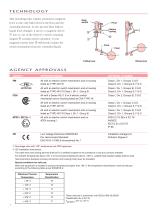

TECHNOLOGY Snap switch Side mounting units employ permanent magnetic force as the only link between the float and the switching element. As the pivoted float follows liquid level changes, it moves a magnetic sleeve ➀ into or out of the field of a switch actuating magnet ➁ causing switch operation. A non- Return spring magnetic barrier tube ¬ effectively isolates the switch mechanism from the controlled liquid. Falling level Rising level APPRoved ModeL APPRovAL CLASSeS All with an electric switch mechanism and a housing listed as TYPE 4X/7/9 Class I, Div 1, Groups C & D Class II, Div 1,...

Open the catalog to page 2

SPECIFICATIONS SWITCH SERIES B, C, D & R DRY CONTACT SWITCHES SERIES F, HS, 8 & 9 HERMETICALLY SEALED SWITCHES • Designs for AC and DC current applications • Ideal for use in salt and other corrosive atmospheres • HS is a positively pressurized capsule for entire mechanism and contacts • Process temperatures to +1000° F (+538° C) SERIES J & K PNEUMATIC SWITCHES SWITCH ENCLOSURES • Suited for applications where electrical power is not available • TYPE 4X/7/9 aluminum enclosures • Designed to meet Class I, Div. 1, Groups C & D and Class I, Div. 1 Group B • Bleed and non-bleed designs •...

Open the catalog to page 3

LEVEL INCHES The level differential may be adjusted by repositioning the jam nuts on the magnetic sleeve stem as shown below. Refer to the charts at right for the minimum and maximum levels obtainable. Upper jam nuts Guide washer Magnetic sleeve Magnetic sleeve stem A. top of attraction sleeve to top of stem B. top of attraction sleeve to bottom of bottom jam nut Pivot Pivot High level CL of control Float stem length minus approx. 3/4" Pneumatic Switches 1 NEMA 1: ⁄4" NPT This dimension equals stem length plus float length, minus 2.50 (64). This dimension equals stem length plus float...

Open the catalog to page 4

LEVEL DIFFERENTIAL VS. MOUNTING NOZZLE LENGTH The tables below may be used to determine the maximum level travel (differential) available between “Switch on” and “Switch off” actuations with mounting nozzles of different lengths. The differentials given occur with the minimum tank opening diameter listed for each model and are applicable to standard controls. Switch actuates rising level Level differential Switch actuates falling level Float Maximum Level differential Available with Several nozzle Lengths ➄ Model T52 with 3.12" Model T63 with 2.31" Model T62 Threaded with 3.06" Model T62...

Open the catalog to page 5

Models available for quick shipment, usually within one week after factory receipt of a complete purchase order, through the Expedite Ship Plan (ESP). MODEL NUMBER, MATERIAL OF CONSTRUCTION AND TANK CONNECTION Set Model Points Code Material of Construction description Cast Iron body, 300 Series SS trim, 400 Series SS sleeve Cast Iron body, 316 SS trim and sleeve Carbon Steel body, 300 series SS trim, 400 Series SS sleeve Carbon Steel body, 316 SS trim and sleeve 304 SS body, 300 Series SS trim and sleeve Pressure Rating➀ Tank Connection description 4" Cast Iron Square Flange 3" NPT 3" 150...

Open the catalog to page 6

ELECTRIC SWITCH MECHANISM AND ENCLOSURE Switch description All models with Material of All models with Material of Construction Code 1, Construction Codes 2, 3 & except model T64 4, except model T64 Process ➄ Temperature Set ≈ Contacts Range Points °F (°C) Class I, Div 1 Class I, Div 1 Groups C&D Series B Snap Switch Series C Snap Switch DPDT SPDT DPDT Series D DC Current -40 to +250 Snap Switch (-40 to +121) SPDT DPDT Series F -50 to +750 Hermetically Sealed (-46 to +399) Snap Switch SPDT DPDT Series HS Hermetically Sealed -50 to +550« 5-amp Snap Switch (-46 to +288) with Wiring Leads TyPe...

Open the catalog to page 7

QUALITY The quality assurance system in place at MAGNETROL guarantees the highest level of quality throughout the company. MAGNETROL is committed to providing full customer satisfaction both in quality products and quality service. The MAGNETROL quality assurance system is registered to ISO 9001 affirming its commitment to known international quality standards providing the strongest assurance of product/service quality available. Several Liquid Level Switches are available for quick shipment, usually within one week after factory receipt of a complete purchase order, through the Expedite...

Open the catalog to page 8All Magnetrol - AMETEK catalogs and technical brochures

-

Interface In The Field

14 Pages

-

Emulsion In The Field

9 Pages

-

PRODUCT LINE CATALOGUE

106 Pages

-

Aurora® Magnetic Level Indicator

28 Pages

-

Atlas™ Magnetic Level Indicator

24 Pages

-

STEAM DRUM LEVEL MATTERS

1 Pages

-

INTERFACE IN THE FIELD

1 Pages

-

Echotel® 355

4 Pages

-

Echotel® 335

4 Pages

-

Power Generation

16 Pages

-

Petroleum Refining

16 Pages

-

Natural Gas Processing

12 Pages

-

Seal Pots

4 Pages

-

Mass Flow Measurement

12 Pages

-

Interface Level Measurement

8 Pages

-

Heat Rate Awareness

8 Pages

-

Ethylene Applications

8 Pages

-

Thermatel® TD1/TD2

16 Pages

-

Kotron® 082

4 Pages

-

Enhanced Jupiter®

16 Pages

-

GEMINI™

32 Pages

-

Aurora®

32 Pages

-

Atlas™

24 Pages

-

Horizon TM Model 704

8 Pages

-

Eclipse® Enhanced 705 Hygienic

12 Pages

-

Eclipse® Enhanced 705

8 Pages

-

Pneumatic Tuffy®

12 Pages

-

Models T5x & T6x

8 Pages

-

Models T20/T21

12 Pages

-

Series B73 and Series 75

12 Pages

-

Series 3

24 Pages

-

Model J52

2 Pages

-

Model B40

4 Pages

-

TUFFY® II

12 Pages

-

Digital E3 Modulevel®

12 Pages

-

Floating Roof Detection

16 Pages

-

APM Pneumatic Modulevel®

12 Pages

-

Flue Gas Desulferization

8 Pages

-

Energy Management

4 Pages

-

API 2350 Overfill Prevention

8 Pages

-

PULSAR ® R96

1 Pages

-

Water & Wastewater

12 Pages

-

Displacer Switches

20 Pages

-

Displacer Transmitters

4 Pages

-

Guided Wave Radar

12 Pages

-

Magnetic Level Indicators

12 Pages

-

Magnetostrictive

16 Pages

-

Pulse Burst Radar

8 Pages

-

Thermal Dispersion

12 Pages

-

Ultrasonic Contact

4 Pages

-

Vibrating Rod Switches

4 Pages

-

R Series High Temp Switch

12 Pages

-

Series K Pneumatic Switch

8 Pages

-

J Series Pneumatic Switch

8 Pages

-

Liquid Displacer Level Switches

16 Pages

-

Crude Oil Processing

8 Pages

-

Product Line Quick Reference

8 Pages