Website:

Magnetrol - AMETEK

Website:

Magnetrol - AMETEK

Group: AMETEK

Catalog excerpts

Series 3 Liquid Level Switches ASME B31.1, ASME B31.3 and NACE Construction DESCRIPTION Series 3 float-actuated level switches meet ASME B31.1 or ASME B31.3 requirements. They are designed to provide critical alarm set points in clean liquid applications. FEATURES • NACE MR0175/MR0103 construction available for flanged cage models • 14-inch (356 mm) side/side process connections available as standard • Choice of sealed or flanged float chamber design • Service pressures up to 1680 psig (115.8 bar) for ASME B31.1 and 2240 psig (154.4 bar) for ASME B31.3 & NACE • Process temperatures up to +1000 °F (+538 °C) • Specific gravity ratings as low as 0.33 • Choice of TYPE 4X/7/9, Group B, C & D or EEx d IIC T6 housings • Agency approvals include FM, CSA, ATEX and SAA • ASME B31.1, B31.3 or NACE Certificate of Conformance supplied • ASME B31.1 model with Cr-Mo chamber • Choice of available switch styles, including dry contact, hermetically sealed, pneumatic bleed and non-bleed • Choice of single or multiple switches for single or staged applications • 1", 1/2" or 2" tank connections available in either NPT, socket weld, flanged side/side or flanged side/bottom configuration • Special materials of construction available upon request • Available with special coatings including Epoxy, Carbo Zinc® 11 Primer and Carboline Top Coat, Dimetcote® and Amercoat® • Optional high or low temperature insulation available ASME B31.1 construction for use on boilers and in power plants. • Feedwater heaters • Steam drums • Condensate drip pots • Flash tanks ASME B31.3 construction for use in refineries and petrochemical plants. • Gas/oil separators • Receivers • Knockout drums • Flare pots • Crude/salt water separators •

Open the catalog to page 1

TANK CONNECTIONS AND INSTALLATION DIMENSIONS In addition to the standard slip-on or weld neck R.F. flanges, many other process, vent and drain connections are available, including: • Socketweld • DIN Special flange gasket surface finishes are also available, and cages may be manufactured to allow special process connections. MATERIALS OF CONSTRUCTION Chambers and internal components on some models available in other metal alloys. • 304 SS • 316 SS • Carpenter 20® • Duplex Stainless Steel WELDING Stress reliev i ng of cha mber welds is available for flanged cage models and...

Open the catalog to page 2

A permanent magnet © is attached to a pivoted switch actuator ©. As the float or displacer ® rises with the liquid level, it raises the attraction sleeve © into the field of the magnet, which then snaps against the non-magnetic enclosing tube ©, actuating the switch ©. The enclosing tube provides a static pressure boundary between the switch mechanism and the process. On a falling level, an inconel spring retracts the magnet, deactuating the switch. MODEL APPROVED APPROVAL CLASSES All with an electric switch mechanism and a housing listed as TYPE 4X/7/9 All with an electric switch mechanism...

Open the catalog to page 4

SWITCH MECHANISMS AND ENCLOSURES SERIES B, C, D & R DRY CONTACT SWITCHES • Designs for AC and DC current applications • Process temperatures to +1000 °F (+538 °C) SERIES F, HS, 8 & 9 HERMETICALLY SEALED SWITCHES • Ideal for use in salt and other corrosive atmospheres • HS is a positively pressurized capsule for entire mechanism and contacts • Process temperatures to +1000 °F (+538 °C) SERIES J & K PNEUMATIC SWITCHES • Suited for applications where electrical power is not available • Bleed and non-bleed designs • Process temperatures to +400 °F (+204 °C) SWITCH ENCLOSURES • TYPE 4X/7/9...

Open the catalog to page 5

For float operated units, levels are dependent upon the NOTE: Actuation levels for saturate steam service ratings are shown for single switch units with 1" process connections only. specific gravity of the process media. Consult factory for units with two and three set point and 1)2" or 2"

Open the catalog to page 6

For float operated units, minimum specific gravity and actuating levels vary depending upon the material of construction code used with the unit. For displacer operated units, minimum specific gravity and actuating levels vary depending upon the temperature at which the unit is operated. NOTE: The minimum specific gravity and actuating levels shown are for single switch units with 1" process connections only. Minimum specific gravity and levels will change for multistage units and levels will change for units with 1/2" or 2" process connections. Consult factory for these changes. The level...

Open the catalog to page 7

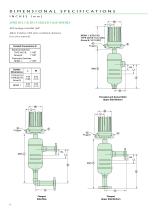

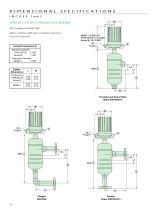

ASME B31.1 & B31.3 SEALED CAGE MODELS All housings rotatable 360°. Allow 8 inches (203 mm) overhead clearance for cover removal. Conduit Connections K Electrical Switches TYPE 4X/7/9: 1" NPT Group B: 1" NPT Pneumatic Switches 1 NEMA 1: ⁄4" NPT Outline Dimensions Threaded and Socket Weld Upper Side/Bottom M L L Flanged Side/Side Flanged Upper Side/Bottom

Open the catalog to page 8

SEALED CAGE MODELS — ASME B31.1 150# & 300# ANSI PRESSURE RATINGS ASME B31.3 ALL PRESSURE RATINGS CHAMBERS WITH 1- INCH CONNECTIONS INCHES 1" NPT Threaded Model & Socket Weld Code A B C B34 1" Flanged 1" Flanged Upper Side/Bottom Side/Side D F G J E H Std. 14" Std. 14" Std. 14" Std. 14" 8.76 3.63 13.84 12.87 — 6.38 17.95 — 13.62 — 6.38 18.70 — 1" NPT Thread & Socket Weld 1" Flanged 1" Flanged Upper Side/Bottom Side/Side D F G J B C E H Std. 14" Std. 14" Std. 14" Std. 14" 92 352 327 — 162 459 — 346 — 162 478 — CHAMBERS WITH 112 - INCH CONNECTIONS ⁄ INCHES 1 ⁄2" NPT Threaded & Socket Weld 1...

Open the catalog to page 9

ASME B31.1 & B31.3 SEALED CAGE MODELS All housings rotatable 360°. Allow 8 inches (203 mm) overhead clearance for cover removal. Conduit Connections K Electrical Switches TYPE 4X/7/9: 1" NPT Group B: 1" NPT Pneumatic Switches 1 NEMA 1: ⁄4" NPT Outline Dimensions Threaded and Socket Weld Upper Side/Bottom M L L Flanged Side/Side Flanged Upper Side/Bottom

Open the catalog to page 10All Magnetrol - AMETEK catalogs and technical brochures

-

Interface In The Field

14 Pages

-

Emulsion In The Field

9 Pages

-

PRODUCT LINE CATALOGUE

106 Pages

-

Aurora® Magnetic Level Indicator

28 Pages

-

Atlas™ Magnetic Level Indicator

24 Pages

-

STEAM DRUM LEVEL MATTERS

1 Pages

-

INTERFACE IN THE FIELD

1 Pages

-

Echotel® 355

4 Pages

-

Echotel® 335

4 Pages

-

Power Generation

16 Pages

-

Petroleum Refining

16 Pages

-

Natural Gas Processing

12 Pages

-

Seal Pots

4 Pages

-

Mass Flow Measurement

12 Pages

-

Interface Level Measurement

8 Pages

-

Heat Rate Awareness

8 Pages

-

Ethylene Applications

8 Pages

-

Thermatel® TD1/TD2

16 Pages

-

Kotron® 082

4 Pages

-

Enhanced Jupiter®

16 Pages

-

GEMINI™

32 Pages

-

Aurora®

32 Pages

-

Atlas™

24 Pages

-

Horizon TM Model 704

8 Pages

-

Eclipse® Enhanced 705 Hygienic

12 Pages

-

Eclipse® Enhanced 705

8 Pages

-

Pneumatic Tuffy®

12 Pages

-

Models T5x & T6x

8 Pages

-

Models T20/T21

12 Pages

-

Series B73 and Series 75

12 Pages

-

Model J52

2 Pages

-

Model B40

4 Pages

-

TUFFY® II

12 Pages

-

Digital E3 Modulevel®

12 Pages

-

Floating Roof Detection

16 Pages

-

APM Pneumatic Modulevel®

12 Pages

-

Flue Gas Desulferization

8 Pages

-

Energy Management

4 Pages

-

API 2350 Overfill Prevention

8 Pages

-

PULSAR ® R96

1 Pages

-

Water & Wastewater

12 Pages

-

Displacer Switches

20 Pages

-

Displacer Transmitters

4 Pages

-

Guided Wave Radar

12 Pages

-

Magnetic Level Indicators

12 Pages

-

Magnetostrictive

16 Pages

-

Pulse Burst Radar

8 Pages

-

Thermal Dispersion

12 Pages

-

Ultrasonic Contact

4 Pages

-

Vibrating Rod Switches

4 Pages

-

R Series High Temp Switch

12 Pages

-

Series K Pneumatic Switch

8 Pages

-

J Series Pneumatic Switch

8 Pages

-

Liquid Displacer Level Switches

16 Pages

-

Crude Oil Processing

8 Pages

-

Product Line Quick Reference

8 Pages